One such specialized appliance used in the metalworking industry is a hydraulic metal brake. Special-purpose machines, which are used to manufacture goods or components and assembly with dedicated tools like hydraulic press equipment that is designed for bending metal sheets at the certain angles of accuracy.

Hydraulic Metal Brakes: Hydraulic metal brakes are just like manual models but offer an automatic operating system ensuring that the clamping, bending and release mechanisms work in tandem with one another. They are therefore more efficient and dependable in contrast to a few of the other metal brakes you can buy. These machines bend the metal sheets through hydraulic systems, so that these are pressed with desired pressure and get turned into specified shapes as required - always delivering high-grade quality.

A hydraulic metal brake is a boon to businesses that deal with the fabrication of metals as it saves downtime, adds value and economizes most procedures. These machines allow workers to form lots of complicated bends in metal sheets very quickly and accurately - this time savings translates into price financial benefits throughout the assembly method.

Besides, the hydraulic sheet metal brake used in fabrication shops are very user-friendly and is low on maintenance-padding making it a must-have for any fabricator. Operators can help squeeze maximum performance from this equipment and extend its productive life with some very basic courtesies.

For working in a hydraulic metal brake safety should be at first place, so use all the protective gadgets such as gloves, glasses and earplugs (and dust mask, but this one is not that important) Moreover, precise measurement of the metal sheet before bending it reduces waste and uses resources efficiently.

Crucial to reaching the desired result is setting both which waythe metal needs to be bent and how much pressure there will needto be across a given thickness; this dictates blade-gap. Operators can use the hydraulic system to carefully apply pressure, and then simply remove it once the metal sheet has been properly bent.

If you own a hydraulic metal brake, here are some ways to keep it performing efficiently and effectively through regular maintenance. This will involve tasks such as: Oil level check, Machine clean down and blade inspection to look for any ware on the blades. Similarly when you use the right blades and accessories for your metal type, it increases the amount of precision in bends while simultaneously reducing damage to material.

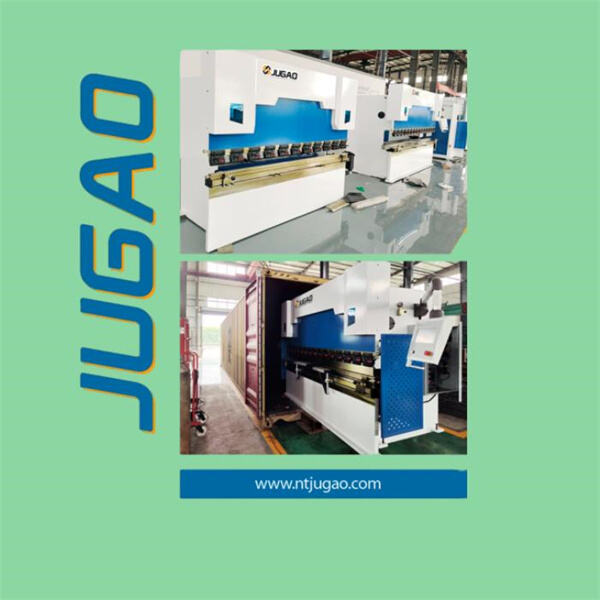

understand importance RD support after-sales. provide full assortment after-sales service include Spanish-speaking after-sales Hydraulic metal brake well as other products. continuing invest development products update latest technology. helps us meet evolving customer requirements keep position leader market.

Quality Builds Trust. believe sheet metal equipment make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines strive provide top-quality products ease anxiety customers.We respond rapidly market Hydraulic metal brake using effective supply chain production management. ample inventory, delivery time shortened one week, allows rapid acquisition equipment gaining advantage market.

Press Hydraulic metal brake renowned efficiency accuracy used many metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting fulfill requirements complex patterns; Rolling Machines specialized forming metal sheets ensure top quality production. Pipe Bending Machines offers flexible pipe bend solutions. product line focuses efficiency, precision, stability help customers improve production efficiency product quality.

Hydraulic metal brake efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.