A press brake is a unique machine that allows to transform flat metal plates into numerous shapes. It essentially forces the metal sheet down so that it takes on the bend we want. This bend has a lot of significance in the world while constructing for metal products. A press brake can be used in different ways, mainly air bending and bottom bending or coining. Each method results in bends and shapes of different kinds.

A press brake is a clever, precise tool with which you can bend metal sheets into useful shapes. It produce basic designs such as U-bends, L- bends and Z-bends. These shapes are used in countless familiar objects. Besides that, the machine can produce flanges (those flat pieces protruding from other metal), slots and even holes wouldn't be a problem on this increase of metal sheet. Press Brake has more specialization because of this it can use in a various kind, so these are very assistive for the industries and workshops

Press brake: The press brake works by placing the flat metal sheet on top of its base, which is a level area where the metal lies. The operator, who is the person using that machine then selects correct tool and die. The tool and die are specialized pieces that assist in forming the metal correctly. Only after that the metal sheet is placed between tool and die, press brake moves on it to give particular shape bend. They also use a gauge to guarantee the aspect of bend is perfect. When the metal sheet has been perfectly bent, it comes out of the machine.

Press brakes are fantastic for they will accurately hold a metal sheet in-check, which you can then bend into various shapes. And they are very flexible, so it can use in the different gauge of metals. This means from anywhere are very thin aluminum sheets to much thicker steel sheets. The press brake guarantees that the metal bends properly, which allows for consistent shapes to be made repeatedly. Consistency is essential in manufacturing because it allows each part to be made the exact same way, every time.

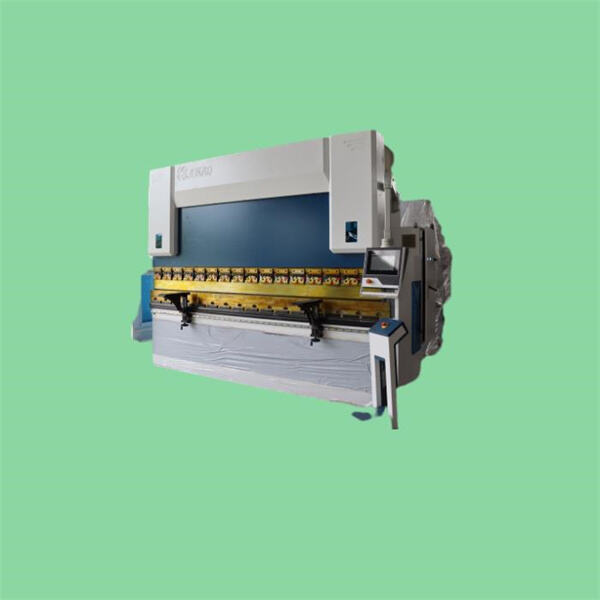

Brake technology has come a long way. Today, we have computerized machines known as CNC (Computer Numerical Control) machines. These sophisticated equipment can also be used to mold metal into precise angles and forms. This would allow the operator to enter a desired pattern in computer programming, and let the machine do rest of everything. This will save a significant amount of time and prevent mistakes that might occur during manual bending. Bending programs can even be remembered by CNC machines. This feature allows you to easily create many copies of the part without reconfiguring everything.

One of the highlights is that it now offers an ATC - or automatic tool changer. This special tool allows the operator easily and quickly switch tools This is beneficial for it saves time and makes everything run faster. Rather than spending a lot of time changing tools, the operator can instead just get back to bending metal.

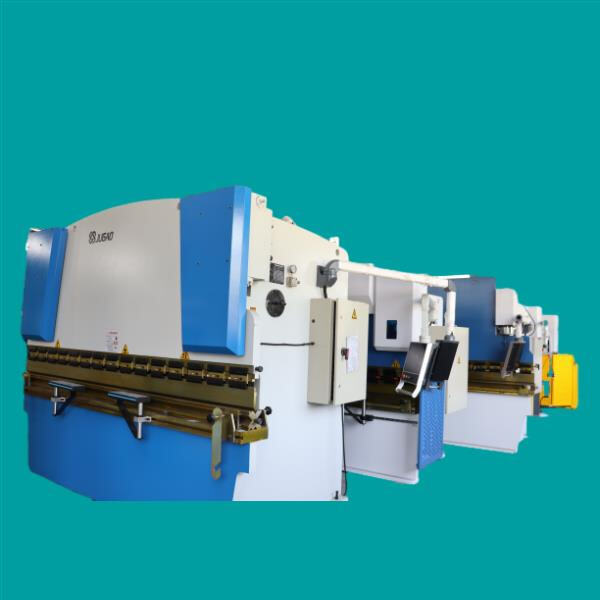

Press brake metal forming Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.

Press brake metal forming brakes ideal complex bending operations high pressure accuracy laser cutting machines able deal range different materials efficient high-precision cutting capabilities; Rolling machines, thanks excellent forming capabilities effective production, satisfy needs large variety clients. Needs mass production. Pipe bending machines suitable various pipe processing due flexibility bending dependable performance. essentials industrial technology help manufacturing sector tackle various challenges efficiency, accuracy flexibility.

recognize importance service sales Press brake metal forming advancement. laser cutting machines, rolling machines, pipe bending machines, products, provide full range after-sales assistance includes Spanish after-sales services, ensure customers worry-free use. continue invest product development upgrade using latest technologies. helps meet evolving customer requirements keep top position market.

Quality Builds Press brake metal forming: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.