Sheet Bending Machine- a valuable Add-on to Industrial Operation

Metal sheet bending machines are very helpful across many industries as tbey help not only to bend metal sheets, but also helps in making the process more efficient and precise. In this article, we take a deep dive into the importance of these machines, and discuss relevant information about how to use sheet metal bending machine effectively, pick out your best choice suited for your needs and also explore top brands alongside models in the market with latest technological developments so far.

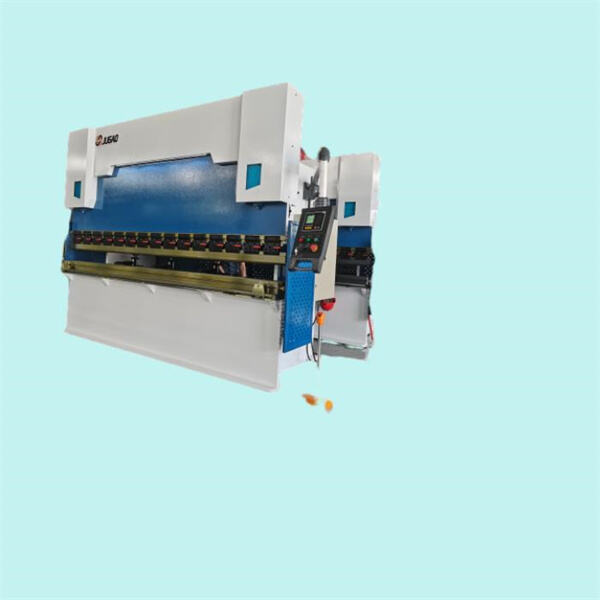

The Press Brake is one of the most used machines - it is hydraulic and can perform bending on different formats for metal sheet. There are two types - the mechanical press brake, used for smaller tasks, and the hydraulic press brake preferred for large industrial process.

One popular machine is the Folding Machine; this gadget has been developed to fold metal sheets into complex and intricate shapes. The machine is used in industries that range from architecture, aerospace and HVAC to enable quick twisting of metal sheets with a high level of accuracy.

How to Operate Metal Sheet Bending Machines with Expert Guidance

A metal sheet bending machine must be handled with great care. Consult with professionals on the matter, and get some helpful tips for a smooth-running operation.

Stay safe and wear gloves, safety glasses and ear protection.

Always perform the machine verification and cleaning of it prior to use. It must be clean for work!

Choose the right tooling for a bend and clamp it properly

Adjust the stroke length and speed of your machine i. e. make it compatible with nature of particular job done by you

Follow the bending sequence of course, to get started right.

Do not overload the machine with metal sheets beyond its capacity.

Make sure your metal sheet is properly positioned, and then turn the machine on.

Keep clear of any moving parts during operation.

Choosing the Perfect Metal Sheet Bending Machine for Your Firm

One of the most challenging jobs for any business is to choose which metal sheet bending machineusinessto buy. SafetyWhen you decide, it should include the safety factor.

The types and thicknesses of metal sheets that you expect to work with.

Precision bending to prevent expensive errors.

These tools deliver production capacity in line with the bending demands of your business.

Continuous maintenance and repair needs for smooth operation

Popular Brands and Models of Bending Machines for Metal Sheets

In the market, there are several brands and types that specialize in their accuracy and top-notch characteristics. Here are a few examples of top brands to consider :

Durma: The Durma AD-S series press brake is famous for its precise bending and fast cycle times.

Amada!!! The most famous reliable and precise HFE series hydraulic press brake made in Amada.

Bystronic: The Bystronic Xpert Pro press brake is considered to be one in all the simplest offered with options like dynamic crowning, 3D visual image.

46) LVD PPEB series press brakeTo offer greater Y, X axis and a range of heights options for better performance the classical model is designed to go easy on that you pocketLVF-NC: The versatile eccentric presses bySmart system controls 09 auxiliary programmable axesso Mold opening speed can adjust independently as bending speeds.

Metal sheet can now be bent Metal Sheet Bending also involves most modern Equipment like;

Sophisticated computer programming for elaborate bends as per needs.

Fully automated part loading & unloading to maximize your production.

Laser bending technology uses lasers to make precise bends, improving the accuracy of a bend.

Sheet bending machines have changed the way industrial operations were executed and greatly improved precision of sheet metal shaping, thereby creating economic value for many businesses. This involves determining:Which machine is right for your businessFactors to consider are the type of metal sheets, bending accuracy, production capacity and needs for use in easy maintenance. With best practices and keeping abreast with the freshest in technological innovations, you are sure not to go wrong metal sheet bending machines database for industrial operations.

Press Metal sheet bending machine renowned efficiency accuracy used many metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting fulfill requirements complex patterns; Rolling Machines specialized forming metal sheets ensure top quality production. Pipe Bending Machines offers flexible pipe bend solutions. product line focuses efficiency, precision, stability help customers improve production efficiency product quality.

Quality Builds Metal sheet bending machine: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.

Press brakes suited bending tasks require high pressure accuracy; Laser cutting machines manage wide range materials efficient high-precision cutting capabilities; Rolling machines, superior forming capabilities Metal sheet bending machine production, can requirements huge number customers. Production requirements mass production; Pipe Bending machines ideal various pipe processing due bending flexibility stable performance. products embody essence modern industrial technology help manufacturing industry adapt various challenges, accurately flexibly.

understand importance RD support after-sales. provide full assortment after-sales service include Spanish-speaking after-sales Metal sheet bending machine well as other products. continuing invest development products update latest technology. helps us meet evolving customer requirements keep position leader market.