So, welcome to the interesting world of press brakes! Have you ever thought that what is a press brake? A press brake is machine used to bend and mould sheet metal into its various forms. Machines are vital to many industries including car production, airplane construction and buildings. Almost all these industries depend on press brakes to make the parts from metal which are an essential component of their product. Now we have a newer updated version known as the automatic press brake. So, dive in to know how revoke works and why it is useful.

Press brakes used to be machinery which people worked very hard on. Workers would spend time individually tweaking the machine's settings, aligning the metal sheet correctly and inspecting it closely to see how their changes caused has affected how that hunk of steel was going bend. This took a long time and made the workers tired. They had to be very cautious while working. Now days with the automatic press brakes,the machine alone can work on bunch of jobs.

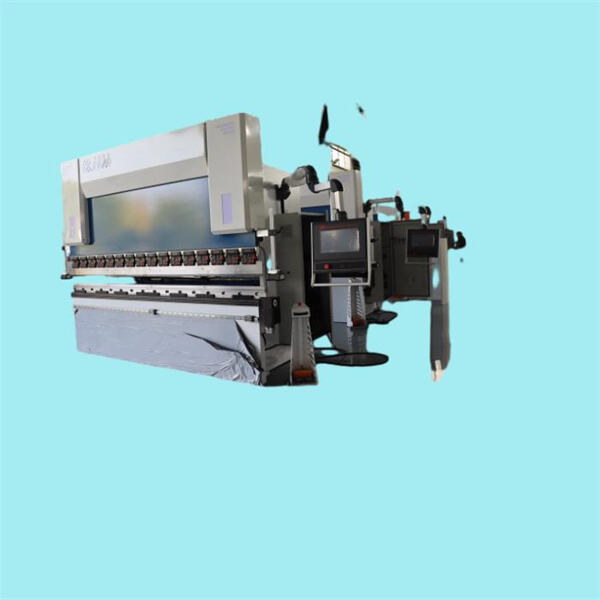

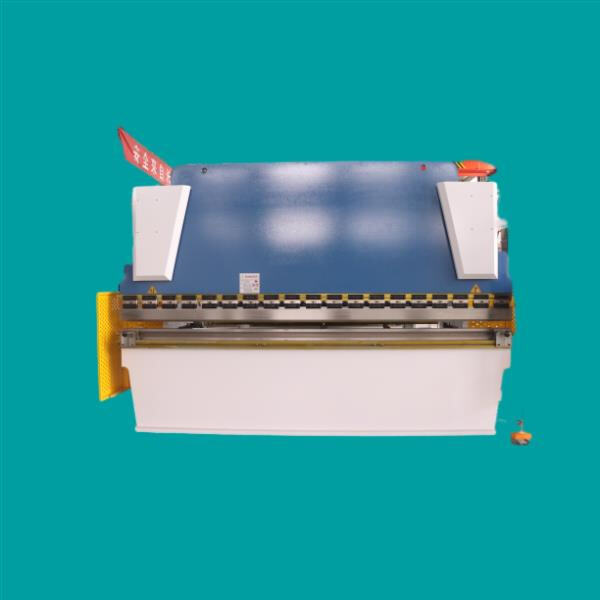

Automatic Press Brake oPress Break An automatic press brake is a type of computer operated machine that uses an automated bender when bending the metal. All that is required of the machine operator is to punch in the exact bend angle and length they prefer. Then all you have to do is enter that info and from there the machine does the actual work! So the above automation helps here to save your time and reduces probability of error. This makes the work faster and correct leading to benefiting everyone in action.

So, when we say about fabrication; it means the formation of metal structures by cutting and bending from different parts. It is a meticulous thing, which must be done with the utmost care and attention to detail as everything needs to fit right. An automatic press brake saves a lot of time and effort when bending metal on the installation, thus increasing efficiency within fabrication processes.

The automatic press brake has readout of the bend angle, a breeze for operator to enter what he wants. This helps to guarantee that every blank is deformed in the same manner, which is crucial for good part fit during final assembly. If all the layers are bending uniformly, it decreases the risk of mistakes and raises up a good final quality deployed output. The automatic press brake is also capable of working very quickly and efficiently so that a higher production can occur within the lesser period.

The automatic press brake is also has the other great advantage of being much faster. It has the ability to bend metal sheets a lot quicker than any person could do it manually. That is code for faster production, and therefore lower costs of labor to be made. Moreover, since the device operates it automatically does much of its own hence mitigating errors from making by an operator. This not only means a more secure procedure but also one that is verifiable.

It is automated so with each manufacturing cycle, there are no interruptions. What this does is produce more products in less time. They can also schedule production runs when they are less busy, during off-peak hours. Thus, is becoming proficient in its overall productivity gives upper-hand and best utilization of resources to companies. When using automatic press brakes, businesses can manufacture more products on the same terms of payment for labor and with less downtime.

Press Brakes renowned accuracy efficiency ideal variety processes metal sheets; Laser Cutting Machines achieve high-speed Automatic press brake cutting order meet complex pattern requirements; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability order improve production effectiveness quality products.

Quality Automatic press brake Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

Automatic press brake brakes ideal complex bending operations high pressure accuracy laser cutting machines able deal range different materials efficient high-precision cutting capabilities; Rolling machines, thanks excellent forming capabilities effective production, satisfy needs large variety clients. Needs mass production. Pipe bending machines suitable various pipe processing due flexibility bending dependable performance. essentials industrial technology help manufacturing sector tackle various challenges efficiency, accuracy flexibility.

recognize importance after-sales service RD advancement. press brakes, laser cutting machines, rolling machines, pipe bending machines, other products, provide entire range support after sales includes Spanish after-sales service, make sure customers enjoy Automatic press brake experience. same time, continue make investments research development encourage latest technology product development meet ever-changing needs customers, assist customers maintain position market.