One of the most important equipment that Hydraulic Press Breaks is because they allow shaping large sheets of metal into desired shape in factories. They are commonly used shaping many materials but metals hold the forefront of what these machines can handle and accomplish in designing various goods. The JUGAO Hydraulic Press Brake one of the reasons why most in this particular industry prefers using equipments from Jugao as their machines are just strong and yet very well priced for what these tools can deliver.

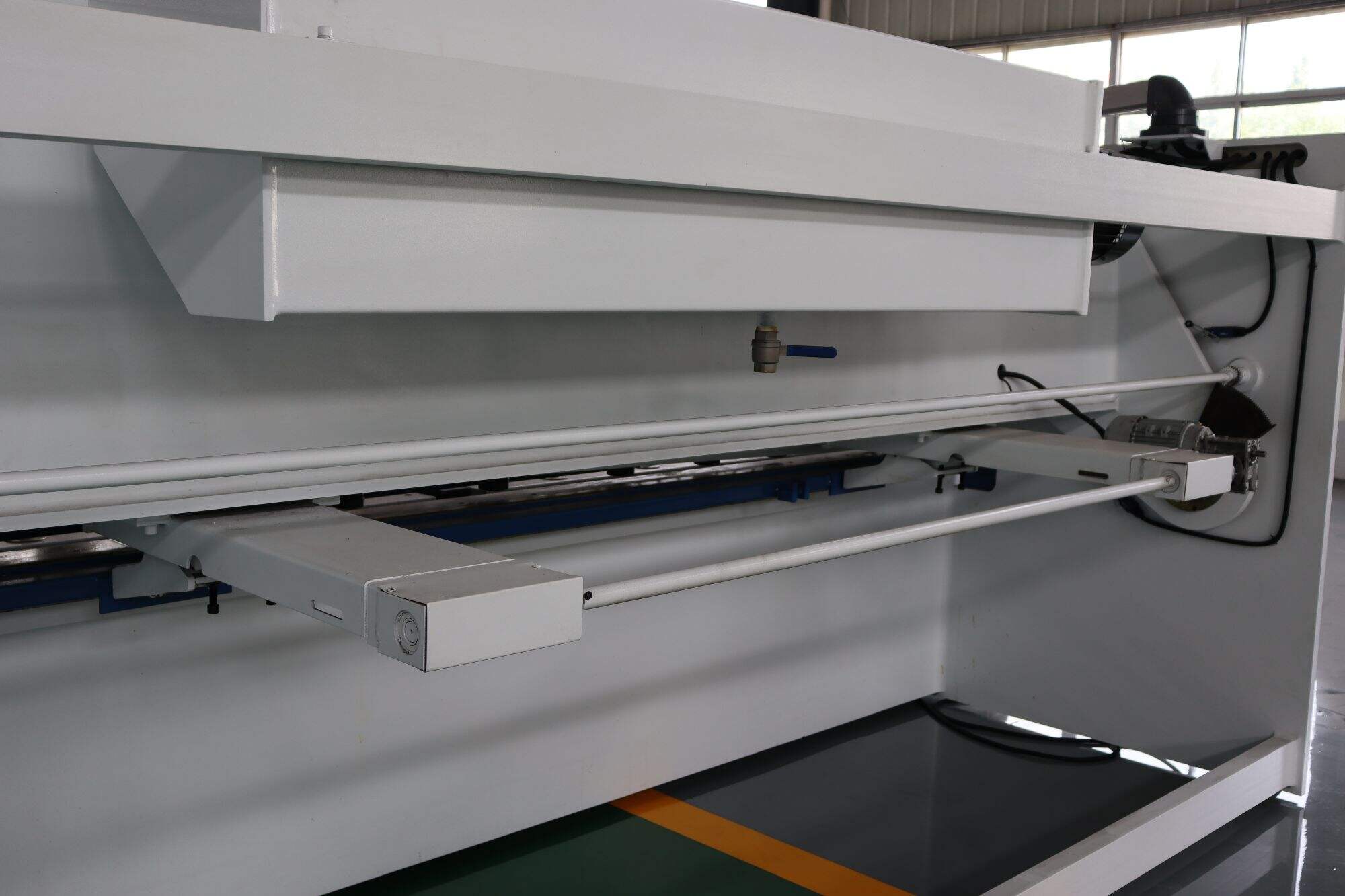

Hydraulic Press Break: It is a machine that bends the materials to differing shapes by applying The hydraulic force. Hydraulic pressure is created by Cylinder and Ram. The Cylinder is fluid filled, as Miguel explains-fluid; as the Ram pushes down it transfers force away into that metal piece. Hydraulic press breaks have the power to process metals in U, Vorum L shapes etc and all worldwide branded Hydraulic Press Breaks are available at every manufacturers. They all present their own individual features that will suit particular job and task areas.

The cnc hydraulic press brake play an important factor in numerous factories and industries. Workers help bend metal sheets into different form of shapes. For example, in the automotive industry: Sheet metals are used for automotive panels and motorcycle parts. Construction: This sheet is commonly used in the construction sector for building and other structures. These are formed in many of the projects and it is very important that exact n accurate bending is there to achieve success in multiple project.

JUGAO brand cnc hydraulic press brake machine and JH21 series are popular with accuracy customers. Metalwork, or where the most minute of errors could make an item worthless. Therefore, you will find that these machines come with modern technology because of which they can produce the perfect bends. The ability to bend extremely thin metal sheets without fear of cracking is crucial, chiefly for the part quality in ensuing operations.

Over the years hydraulic Press Breaks have developed substantially. The mechanical press break is a history old machine/ Machine was first time developed long ago. These were hand pressure levers and took two Andon Pull cords which workers had to manually operate. A lot of this is now digitalization. This is where accuracy and control can be enhanced with computers. The hydraulic press breaks such as 350 ton hydraulic press under JUGAO brand are CNC, which can provide automatic bending and shorten the duration of the steel processing. Well, this technology would be able to produce more complex round shapes with ease.

This is the hydraulic press JUGAO breaks brand best solution any metalworking work. Works for almost all kinds of jobs, so they are very flexible. For tasks like cutting sheet metal, hot forming in a range of at least two dozen ways and even laying down small intricate designs where detail is paramount. Simplicity of use is another design feature that separates these vacuum cleaners from the rest. Both feature top-of-the-line safety measures to care for the people working inside and it is (usual) fan-alloy cooling system, which keeps it cool no matter the workload.

recognize importance service sales Hydraulic press break advancement. laser cutting machines, rolling machines, pipe bending machines, products, provide full range after-sales assistance includes Spanish after-sales services, ensure customers worry-free use. continue invest product development upgrade using latest technologies. helps meet evolving customer requirements keep top position market.

Rolling Machines Hydraulic press break metal sheet forming high-quality production. Pipe Bending Machines offer flexible solutions pipe bent. product line focused precision, efficiency, stability, allows customers increase production efficiency improve product quality.

Quality Builds Hydraulic press break: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.

Press brakes suitable bending complex operations due high pressure precision; Laser cutting machines manage wide range materials thanks powerful high-precision cutting capabilities; Hydraulic press break, thanks their exceptional forming capabilities efficient production, satisfy needs large variety clients. Pipe bending machines utilized mass production due flexibility stability. machines core latest industrial technology assist manufacturing industry meet challenges today efficiently quickly, precisely high degree flexibility.