If you have ever studied a metallic object up close, like some type of shiny cup or portion if an automobile Have you ever wonder how it was made. This includes the creation of these metal items with a process known as press-forming! This unique process takes metal and forms it into a huge range of objects, from cups to bowls and even crucial elements used in cars and other machines. It is a complex process that involves great creativity but also science.

The first step in metal press forming is a flat piece of metal known, somewhat unsurprisingly, as the sheet. This sheet is then loaded into a machine known as the press. The press delivers great amounts of force, pressing onto the sheet so that it deforms and takes on a particular shape. The press is versatile in the way it can be used - different methods, such as stamping, bending and stretching are used depending on what the final product will look like (Scinexx.mobi/autoload/05 May 2008).

Metal press forming is not just an art but also the science behind it! The presses work by forcing the metal with force, speed and temperature until it is formed as required. The amount of force the press can exert is huge - hundreds or even thousands of pounds! This strength is required based on how thick the metal actually is as well as what kind of shape a producer would like his final product to be in.

The articles which are manufactured using this concept and technique have very accurate dimensions so there is a term according to that given "DESIGN FOR MANUFACTURE" so the metal press forming is a type of method in manufacturing where you want an exact product, or perfect as based on design in 3D cylinder. It implies that the finished item must be exactly as illustrated by their designer. To begin this process, the designer drafts a comprehensive schematic blueprint which is effectively a manifestation of what one might describe as a map or otherwise plan for the product. This blueprint contains all the sizes, shapes and specific information that products need to be developed.

As soon as the blueprint design is ready, any person responsible for operating a press with use it to ensure the product gets made properly. They stick very closely to our designs down to the secret sauce so that everything is right. Of course, sometimes even the best-laid plans go wrong. This is exactly why testing of a product or output gets very well justified in this case. The product, after being built as per the specification is checked in detail against all requirements specified on that blueprint. If this does not match up, it goes back to the press and is adjusted accordingly for any errors.

For example, computer controlled presses feature an advanced system that are digitally programmed that allow for precise actions. This computer guides the press to produce the final output in an identical way that designer designed, up unto minor details. This contributes to making top-notch products all the time.

One more interesting new technology for metal press forming is 3D printing. 3D printing enables designers to design their products and try out the same in models or prototypes before they go for a final version. This process saves time and money during development acting as a gatekeeper to costly mistakes later in production.

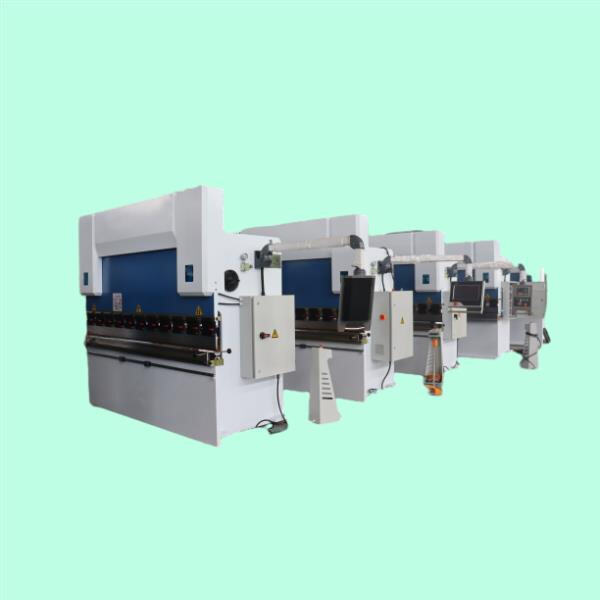

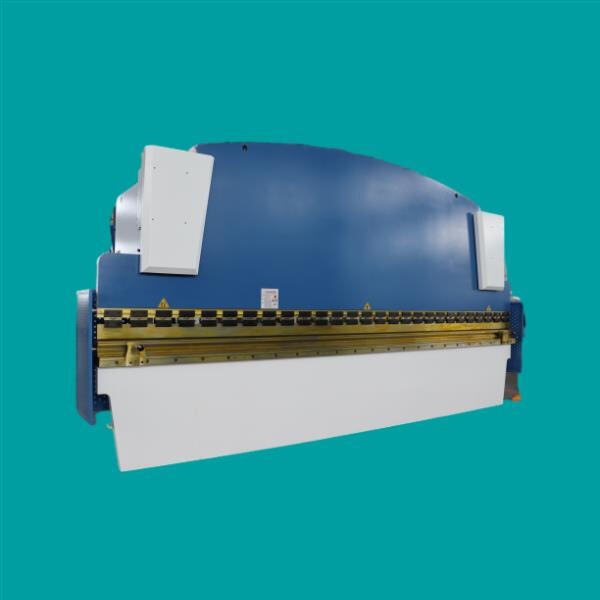

Metal press forming brakes ideal complex bending operations high pressure accuracy laser cutting machines able deal range different materials efficient high-precision cutting capabilities; Rolling machines, thanks excellent forming capabilities effective production, satisfy needs large variety clients. Needs mass production. Pipe bending machines suitable various pipe processing due flexibility bending dependable performance. essentials industrial technology help manufacturing sector tackle various challenges efficiency, accuracy flexibility.

know importance service sales RD Metal press forming. laser cutting machines, rolling machines pipe bending machinery many products, offer entire range after-sales assistance services, Spanish after-sales service make sure customers enjoy hassle-free experience. continue invest product development upgrade technology innovation. helps adapt changing needs customers keep leadership position marketplace.

Press Metal press forming renowned efficiency accuracy used many metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting fulfill requirements complex patterns; Rolling Machines specialized forming metal sheets ensure top quality production. Pipe Bending Machines offers flexible pipe bend solutions. product line focuses efficiency, precision, stability help customers improve production efficiency product quality.

Quality Builds Trust: Metal press forming sheet metal machines meticulously supervise quality control ensure machine is line industry standards. strive provide highest quality products customers. laser cutters press brakes, pipe bending well as rolling machines.Rapid Market Response: leveraging efficient production supply chain management, we able quickly meet market demands. ample inventory, delivery time reduced week, enabling prompt equipment acquisition market advantage.