Breaking the Barriers of Convention through High-Tech 6 Axis Press Brake Machine for Precision Metal Bending

Manufacturing is a complicated industry and it never stops looking for newer ways to make the whole production process easier, reduce need for manpower, and improve quality of the products. Out of the many manufacturing processes, sheet metal bending has undergone some drastic changes in recent times. The following is an exploration of the features that make a 6 axis press brake so valuable to metal bending including speed, precision and ease-of-set-up.

The advantages of 6 axis press brake technology over conventional bending methods It reduces the amount of time and effort it takes for manual setups, first off. In addition, 6 axis press brake automation can run nonstop -for hours and hours before resting- meaning fewer pauses leading to far less downtime which equals time lost and money sunk.

The one distinctive benefit of the 6 axis press brake in technology is its superior precision. For this reason, the quality of metal sheets needs to flawless with perfect bends and that too in a certain amount so robotic folding make sure all products have an equal level. The 6 axis press brake technology provides an accuracy up to the last detail and ensures repeatable precision bends in each part. The bending process is readily modified, making it well-suited to all sizes of production runs as well.

6 axes make bender machines useful for automated making applications. Automation helps to minimize errors be eliminating manual labour, which increases productivity. 6 axis press brakes automated systems will help in speeding up the bending process from loading material to finished part.

Such automated systems are perfect for having exact tolerance, high-volume operations, generate complex geometries and manufacture custom parts. In addition, the production processes of a company can be streamlined to make it faster at an overall cost reduction and increased accuracy and repeatability.

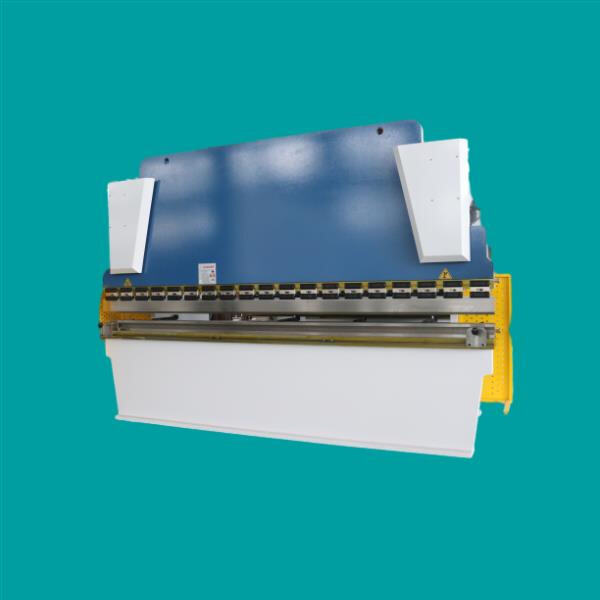

These characteristics makes the 6 axis press brake technology ideal for a broad spectrum of applications. Easy Handling of Complex Geometries and Bends: Operators can produce a wide variety of parts without secondary tooling. Its versatility makes the 6 axis press brake a must-have for any metal fabrication shop.

It is quite easy to obtaining such result, 6 axis press brakes designed for manufacturing complex brackets and items like enclosures & machine frames help you in the process. The capabilities of bending copper, aluminum and stainless steel change Versatreks' technology the most versatile solution on metal forming market.

Bringing 6 axis press brake technology into metal fabrication holds a considerable advantage. The technology simplifies manufacturing, eliminates errors and improves productivity in exchange for large cost reductions. Using 6 axis press brake technology is beneficial, as companies can complete much faster production processes without compromising on quality.

In addition to making this technology scalable which increases the production capacity of a facility without having to purchase more equipment or assign personnel for shift work. Auto bending offers homogeneity, without human factor and most important thing if we summarize the reasons is it eliminates manual labor aspect in stages mentioned above.

In conclusion, the 6 axis press brake technology offers a special line of answer to manufacturers who are in demand for bending metals. It has proven in applications as necessary tools with the capabilities to provide exceptional accuracy, efficiency and versatility over traditional techniques when processing metals on a medical device surface grind. Automating the bending process with 6 axis press brakes results in increased efficiency, reduction of errors downto zero as well as significant cost saving and improved product quality. Moreover, with the advancement in manufacturing industry, 6 axis press brake technology will continue to play a big role in sheet metal fabrication.

Press brakes suitable complicated bending processes due pressure precision laser cutting machines able manage wide range materials because precise precise cutting capabilities. Rolling machines, with excellent 6 axis press brake capabilities efficient production, satisfy requirements huge variety customers. Pipe bending machines utilized mass production adaptability stability. machines embody essence latest industrial technology manufacturing industry respond various challenges efficiently precision, speed flexibility.

Quality Builds Trust. believe sheet metal equipment make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines strive provide top-quality products ease anxiety customers.We respond rapidly market 6 axis press brake using effective supply chain production management. ample inventory, delivery time shortened one week, allows rapid acquisition equipment gaining advantage market.

understand importance RD support after-sales. provide full assortment after-sales service include Spanish-speaking after-sales 6 axis press brake well as other products. continuing invest development products update latest technology. helps us meet evolving customer requirements keep position leader market.

Press 6 axis press brake renowned efficiency accuracy used many metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting fulfill requirements complex patterns; Rolling Machines specialized forming metal sheets ensure top quality production. Pipe Bending Machines offers flexible pipe bend solutions. product line focuses efficiency, precision, stability help customers improve production efficiency product quality.