Box and pan brakes are additional tools that allow people to bend thin sheets of metal into various shapes. Sheet metal - Thin Metal Common Uses in Everyday Life? Rectangular Sheet Meatal Covers For Houses, Steel Sheets for Car and Tin Toys A box and pan brake is a very handy machine for people who regularly work with metal, from welders to roofers and carpenters. This is the reason this article will provide information on all you need to know about box and pan brake including its working.

What I like of box and pan brakes is that they allow to fold the sheet metal into a variety of bends or shapes. The different configurations of the brake allow for workers to make precise bends in their metal work. This accuracy helps keep all of the metal in place near to some other pieces or parts. Workers will bend the metal in various angles, they can form curves with it and sharp corners or even completely circles! This is critical, because at times sheets of metal will have to be adapted for a specific project. For this purpose, you will find box and pan brakes to be of immense help.

That is another great thing about box and pan brakes - they are very quick to use. As a result, bending metal sheets is substantially easier and faster compared to the manual process which can take time as well as toll on your body. A worker can bend many times over in a short period of time with the help of the box and pan brake. Someone that has to move around large pieces of metal can certainly find this useful as it will for sure save them a lot more time and power. Metal tools make the shaping of metal fast, giving workers more time to finish their project faster than ever.

Additionally, these tools are also essential for producing high grade metal products such as the box and pan brake. Since these tools produce exact bends and forms, you can turn that metal fragments into specific parts. Due to the complexity as well as uniqueness of such pieces, it would be almost impossible to make any one with a box and pan brake. For example, if someone wanted to make a piece of metal that is curved with certain dimensions or designs in it; without the use of a box and pan brake this would be incredibly difficult. In one way or another, these tools help make all kinds of things - gorgeous pieces of metal jewelry; vital automotive components; striking architectural details - more easily than otherwise.

Those who operate in metal know the importance of having some essential tools to help them out doing their work better. Box and Pan Brakes are the basic need of usage for metal work in nonetheless. A brake likethis allows workers to do much more with metal, than they could without it. That way, more sheets can be created and manipulated using different processes for many projects from customizing metal enjoys. You would not be able to finish many of your projects, or they will take way longer if you do it without the box and pan brake.

Finally, box and pan brakes allow you to easily form intricate designs in metal sheets. This allows for the metal to be bent in various directions by way of a brake. This adds depth and dimension to the metal that makes it possible for you to make box shapes, cylinders or even pieces of different types fit together like a puzzle. These tools aid in creating complex shapes fast and very efficiently, which is crucial for people who create objects from metal daily. They can produce highly customized objects that would be hard to manufacture otherwise.

Box and pan brakes efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.

understand Box and pan brakes RD as well after-sales assistance. laser cutting machines, rolling machines pipe bending machines products, offer extensive range after-sales support services, including Spanish after-sales support, ensure customers able use product without worry. We continuing invest product development upgrade latest technology. helps us meet evolving customer requirements keep leadership position market.

Quality Box and pan brakes Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

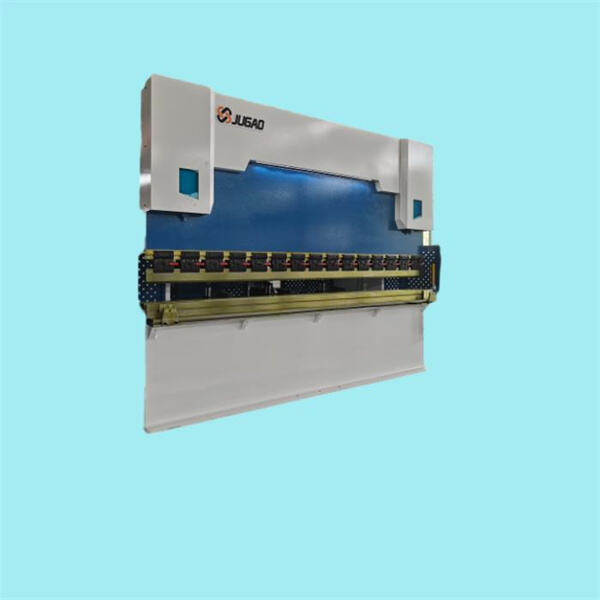

Press Brakes recognized efficiency accuracy suitable various metal sheet processing. Laser Cutting Machines achieve high-speed, high-precision cutting meets Box and pan brakes complicated patterns. Rolling Machines specialized forming metal sheets ensure production quality; Pipe Bending Machines offers flexible pipe bend solutions. product range focused accuracy, efficiency, stability order improve effectiveness quality products.