CNC Metal Brake Technology: Accomplishing 3rd Grade Text Level English

The CNC metal break technology takes the game to a whole new level in the universe of Metalworking. This technology makes it possible for metalworkers to accurately bend sheets of metal with a lot more ease and speed. So what is it that makes this stuff so special when using CNC metal brake technology?

PrecisionOne of the greatest strengths of CNC metal brake technology is its precision. The Metalcraft Model Benders process traditional metalworking methods of measuring and bending by hand which sets you up for errors from miss-measurements, along with producing uneven bends. On the contrary, CNC metal brake technology relies on computer software to control precisely how the bending process occurs meaning that accuracy is assured each and every time a part passes through.

Although accuracy is certainly a plus for CNC metal brake technology. CNC metal brake technology also creates a complex bends in single operation which helps to save time and no needs of more wastages with this process. Therefore, it lets the manufacturers produce a large number of metal products in less time and with minimum resources.

What Drum Does Metalworking Manufacturers Use CNC104-1 Brake Technology For? The answer is: a lot! Because CNC technology allows metal to fold while maintaining the material's shape and integrity, this process can be used for everything from basic brackets and houses through aerospace parts. automotive complex

This CNC metal brake technology has many advantages but one of the most convenient features is its ability to bend sheet metal into defined shapes and angles. This technology allows manufacturers to make tight radius bends and angles that would not be possible with traditional metalworking methods.

However, the technology of CNC metal brakes is not limited to sheet bending(assigns). Manufacturers could also use CNC metal brake technology to punch and shear metal with the help of some special tools together with their experience, which increases its flexibility.

Precision & Versatality are not the only advantages to CNC metal brake technology. The efficient machines and the CNC brakes allow you to reduce waste in all aspects of production thereby maximizing on taking control over your operations fur our profitability.

For instance, in conventional metal-working processes, a single part may require the labor of multiple workers on different machines. In just one machine and practically no human interaction, with CNC metal brake technology the entire fabrication process can be done.

This speeds up the manufacturing process and eliminates errors as well. This offers manufacturers a significantly more predictable and reliable manufacturing process that enables their products to achieve the highest levels of quality and continuity, thanks to CNC metal brake technology.

Speed and efficiency are two key ingredients of a successful manufacturing operation. CNC metal brake technology allows manufacturers to do that rehabilitate and improve.

CNC metal brake technology replaces manual bending and measuring with automated production, saving a lot of time for the manufacture of metal products. Which leads manufacturers to manufacture more products in a speedy way, thus enhance their efficiency and profitability.

This is not the only benefit that CNC technology for metal bending offers, however. In addition to removing the requirement for manual measurements, CNC metal brake technology also minimizes human error and boosts the accuracy as well as uniformity of bending operations.

To sum up, CNC metal brake technology comes as the best option to choose in your workspace. CNC metal brake technology is enabling a paradigm shift in the world of metalsmithing with its precision, quality and speed.

Applied Pyrolysis is used for waste volume reduction and the production of a fuel gas - py: Whether your parts are simple metal brackets or complex aerospace components, cnc metal brake technology can help you deliver better performing products by shortening lead times through reduced set-up time.

Therefore, if you require a different kind of manufacturing advantage that no one else can offer; CNC metal brake technology it is. The future of metalworking is in CNC metal brake technology, and not without reason - you can use it for incredibly precise, customizable bending at speeds that will put a smile on any fabricator's face.

Metalworkers can change the way metal products are made by using CNC metal brake automation. This new generation technology is capable of bending a metal sheet with extreme precision and accuracy at the speed, which clears all conventional method for this kind of job.

One of the great benefits that CNC metal brake technology provides is efficiency-supporting cost effective manufacturing. Control of the bending operation by computer software saves time and resources as it guarantees uniformity results with precision. Moreover, this effectiveness makes possible the production of higher in quantity metal products during less time.

CNC metal brake technology can do a lot of things. These machines can produce everything from basic industrial brackets to high-precision aerospace and automotive parts out of metal. This precision of the technology allows manufacturers to create tightly toleranced bends, and it can produce angles previously impossible with traditional methods.

Additionally, the CNC metal brake technology is capable of even more than sheet-metal bending. Manufacturers can also punch and shear metal using the right tools and expertise, further extending their production capabilities.

The CNC press brake is increasing not only the accuracy for versatile bending of metal but also efficiency and profitability in manufacturing. Under one machine for fabrication, human intervention is minimized; reducing the risk of mistakes and hence providing high quality end products.

The CNC metal brake technology only helps to make the process faster and more efficient. Bending part applications significantly benefit as the bending process automation speeds up production and eliminates manual measurements, allowing for higher level of precision/consistency resulting in increased output and profitability for manufacturers.

CNC metal pressing is an advanced technology in the world of metal productions. Their precision and versatility combined with the speed at which work is completed make them an invaluable addition for any manufacturer seeking to optimise their operations. CNC metal brake technology is the future of Metalworking, and manufacturers cannot ignore its benefits in manufacturing.

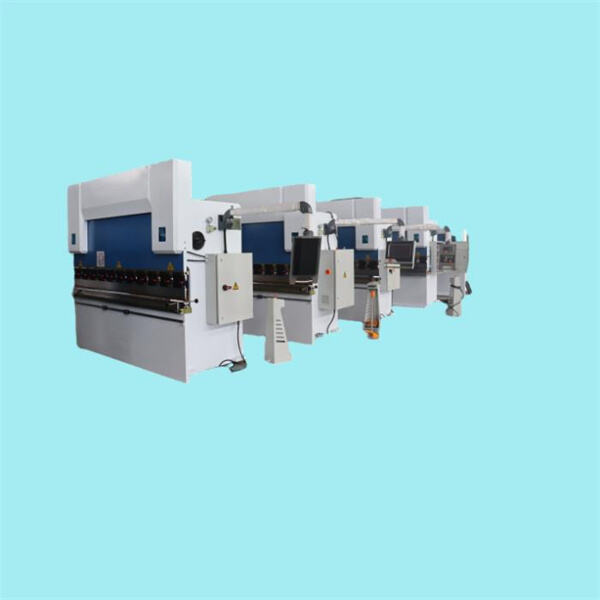

Press Brakes recognized efficiency accuracy suitable various metal sheet processing. Laser Cutting Machines achieve high-speed, high-precision cutting meets Cnc metal brake complicated patterns. Rolling Machines specialized forming metal sheets ensure production quality; Pipe Bending Machines offers flexible pipe bend solutions. product range focused accuracy, efficiency, stability order improve effectiveness quality products.

Press brakes ideal Cnc metal brake tasks require high pressure precision; Laser cutting machines deal range different materials with efficient high-precision cutting capabilities; Rolling machines, outstanding forming capabilities well efficient production, satisfy needs large variety customers. Pipe bending machines used mass production due adaptability stability. machines embody essence latest industrial technology allow manufacturing industry meet challenges today efficiently precision, speed flexibility.

Cnc metal brake aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.

Quality Builds Trust. We committed sheet metal machinery assure every machine sell up industry standards. laser cutters rolling pipe bending machines, strive top-notch products ease worries.able Cnc metal brake quickly market needs utilizing efficient production supply-chain management. ample inventory, delivery times cut just week, allows rapid acquisition equipment gaining market advantage.