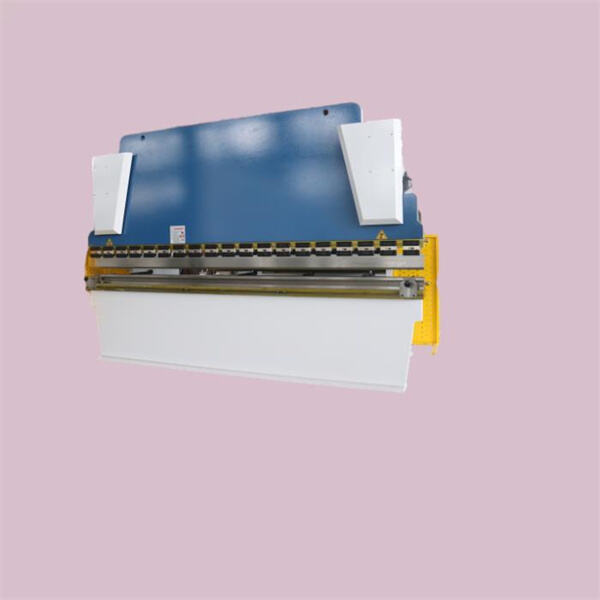

A hydraulic sheet press is a machine of great significance to factories where different products are made, and these can be car parts or even complete boats in the automobile industry among others. A metal sheet might be flat in nature but this machine can convert it into a shape such as curve, or flat surface. This is performed through hydraulic fluid, a liquid that has properties suitable for this setting. The fluid helps the machine to press harder on metal sheets. It actually, when the presser is applied makes that metal to bend or flatten itself in the form we need. Think of JUGAO 350 ton hydraulic press as a big, powerful hand that can push the metal into just about any shape we want.

This is a JUGAO hydraulic sheet press that happens to be built by one of the more reputable manufacturers. This means it can function without needing to stop and in action for a long time. The company provides top-of-the-line products with a consistent appearance each time it makes them. Therefore, this is a boon for factories which will help them to save more time and money. Instead of taking hours to produce only a few units, they can use the hydraulic sheet press machine and manufacture way far more quickly in making so many products. This is helpful for a business because it will enable them to deliver products faster and allow the cost as low.

Factories that purchases hyd press brake can expect great quality metal products. That is because the machine presses down evenly all along a metal sheet. It moulds the CA metals very accurately and neatly to get everything same of next every piece. All factory need this consistency because this what make sure they all parts that the producing are will be able to fit with each other.

Hydraulic sheet press is good news as it lowers the time for construction of products up to 50%. That’s a huge difference. This means that it is able to manufacture many of whatever items the company offers manufacturing for quickly. Since the JUGAO hydraulic sheet press is at work, so machineries of factory require fewer workers for this assist. This is a huge gain for them as cnc hydraulic press brake allows them to bring their products faster on the plate and serve what exactly customer wants.

Before the invention of a hydraulic sheet press, making custom metal products used to be slow and required a great amount craftsmanship. The metal had to be shaped by hand, which was tough and time consuming. But now, you can simply press the sheet of metal with one layer and transform your product within minutes. The cnc hydraulic bending machine are high technological to make sure the products and services provided by them have exactly what a consumer would want. Thanks to that, there are fewer bugs and more satisfaction from clients.

Because of this, hydraulic sheet presses are extremely versatile - capable of producing a wide range products in terms shape and size from metal. Iron dial are special tool for the sheet material adapting, and they have many types of dies to change different shape in one mould with adjustable force requirements. These tools can be tailored to the customer. These hydraulic sheet presses can thus create any type of metal product, no matter how un-common or specific it maybe. When you are working in a factory, whether it be for something as simple as flat piece to more complex curve shape and bend design the hydraulic bending machine has got your back.

Quality Hydraulic sheet press Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

Rolling Machines specialize metal sheet forming high-quality production. Hydraulic sheet press offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Hydraulic sheet press.

Press brakes ideal Hydraulic sheet press tasks require high pressure precision; Laser cutting machines deal range different materials with efficient high-precision cutting capabilities; Rolling machines, outstanding forming capabilities well efficient production, satisfy needs large variety customers. Pipe bending machines used mass production due adaptability stability. machines embody essence latest industrial technology allow manufacturing industry meet challenges today efficiently precision, speed flexibility.