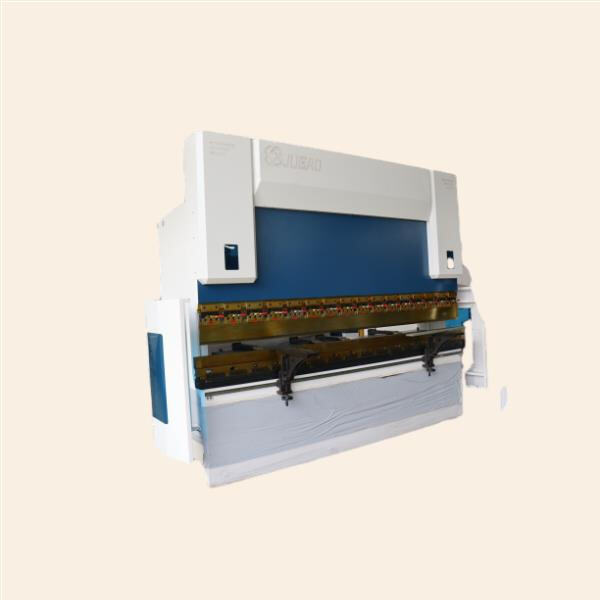

It is a device used in metalworking, such as, hydraulic press brakes manufacture to stylishly bend the metal due its negligence. They do so by using hydraulic fluid and a piston to put pressure on the metal sheet, bending it with ease and accuracy. That is what we will discuss in this article - the advantages along with different applications of a hydraulic press brake.

Hydraulic press brake provides high production efficiency One of the biggest benefits to using a hydraulic press brake is that it can drastically increase productivity in each aspect from manufacturing. These machines can bend a variety of thicknesses and materials with consistent precision, making them suitable for multiple applications. Again, they are quick to set-up so not only will you be spending much less time on this than before, it is also simplifying the manufacturing process.

Besides boosting productivity, hydraulic press brakes also help in saving energy. Hydraulic press brakes use less energy than conventional mechanical driven machines that consume large quantities of electricity to operate their motors and gears. This means that it not only runs faster, but also consumes less energy and cheapens production.

As a leveler,bending accuracy can be said to be one of the most significant benefits of hydraulic press brakes. They are programmable machines made to bend metal with precision, usually for products that require standards set out by the manufacturer In addition to this, you get a trustworthy bend across the whole sheet when using hydraulic press brakes which is important in order for them to provide consistent quality and product. They will also support more intricate bending shapes such as U-bends and V -bend s, along with the ability to place multiple bends on a single sheet.

Hydraulic press brakes are extremely versatile and durable machines, so they make a good addition to the lineup at any metalworking shop. This has a wide number of applications from small projects to full-scale production runs. They may even bend thin aluminum sheets up to large stainless steel plates as well.

Specially, they are designed to endure harsh use because is made with heavy-duty built and premium quality elements. Hydraulic press brakes, when maintained and taken care of properly can be very durable devices that are able to produce the same high quality products for many years.

The fabrication of the products can be achieved in efficient production rates by using hydraulic press brake. These machines are especially adept at bending metal quickly and precisely, which helps to enhance production rates. In addition to this, they can be furnished with robotic arms for automation purposes so that the production process is made faster and a lesser number of laborers are productively used.

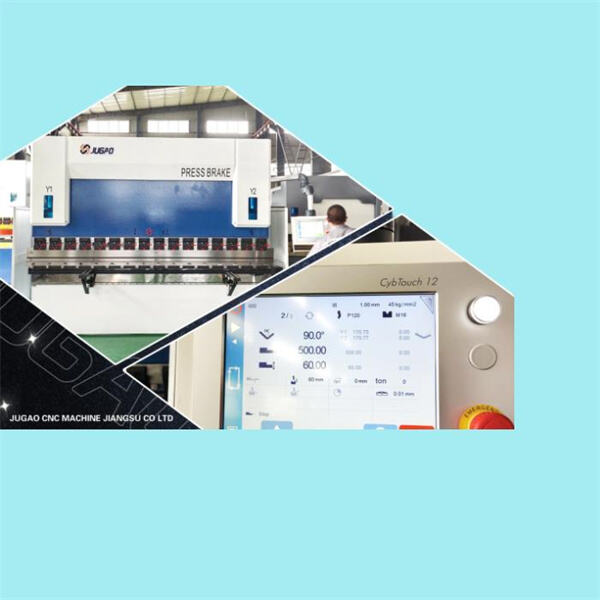

recognize significance RD Hyd press brake. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.

Press Brakes known reliability precision Hyd press brake various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.

Press brakes suited bending tasks require high pressure accuracy; Laser cutting machines manage wide range materials efficient high-precision cutting capabilities; Rolling machines, superior forming capabilities Hyd press brake production, can requirements huge number customers. Production requirements mass production; Pipe Bending machines ideal various pipe processing due bending flexibility stable performance. products embody essence modern industrial technology help manufacturing industry adapt various challenges, accurately flexibly.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor each machine's quality ensure conforms industry standards. laser cutters rolling pipe bending machines, strive top-notch products ease anxiety customers.respond rapidly Hyd press brake demands through efficient production supply-chain management. time deliver can reduced week ample inventory. enables rapid equipment purchases competitive advantage.