The Marvelous Steel Plate Roller: Your Ultimate Solution in Metal Fabrication

Introduction

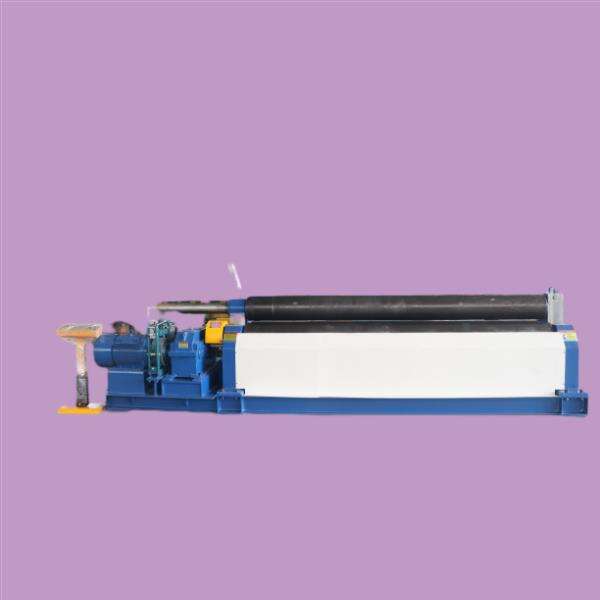

Have you ever seen a big machine that can roll a large sheet of steel into a cylinder or a cone shape? That's the steel plate roller. It's a powerful equipment that can transform flat steel plates into curves or cylinders, making fabrication jobs easier and faster. This article will discuss the advantages, innovations, safety, uses, how to use, service, quality, and application of the JUGAO steel plate roller.

One of the most remarkable advantages of the steel plate roller is its capacity to bend thick metal plates with remarkable accuracy and precision. It can handle a wide range of materials, including sheets of steel, aluminum, brass, copper, and other metals. The JUGAO metal rolling machine can also produce a smooth and fine finish in the rolled metal plates, which improves the overall quality of the fabrication project.

In recent years, there have been significant innovations in steel plate rollers that have revolutionized metal fabrication. For instance, the newest models of steel plate rollers have digital controls and programming systems that enable engineers to customize the bending process based on specific requirements. Some JUGAO plate rolling machine also have automated features such as feeding, rolling, and cutting, which reduce human error and enhance safety.

The steel plate roller is a heavy-duty device, and it requires expert handling and careful attention to safety protocols. Before using a steel plate roller, the operator must wear protective gear such as gloves, eye protection, and a hard hat. The JUGAO rolling sheet metal must also have safety features such as emergency stop buttons, overload protection, and guards to prevent accidents and injuries.

The steel plate roller has diverse applications in various industries such as construction, shipbuilding, aerospace, marine, and automotive. It's used to fabricate components such as tanks, pipes, boilers, and other cylindrical or conical shapes. The JUGAO roll machine is also used in artistic and decorative metalwork, where metal sheets are rolled into intricate designs, patterns, and textures.

Press brakes suited bending tasks require high pressure accuracy; Laser cutting machines manage wide range materials efficient high-precision cutting capabilities; Rolling machines, superior forming capabilities Steel plate roller production, can requirements huge number customers. Production requirements mass production; Pipe Bending machines ideal various pipe processing due bending flexibility stable performance. products embody essence modern industrial technology help manufacturing industry adapt various challenges, accurately flexibly.

Steel plate roller importance RD support after-sales. press brakes, laser cutting machines, rolling machines pipe bending equipment items, offer extensive range after-sales support includes Spanish after-sales service, ensure customers able use product without worry. continuing invest product development upgrade technology innovation. allows us meet evolving customer requirements keep leadership position market.

Steel plate roller Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease anxiety customers. can respond Steel plate roller market demand leveraging efficient production supply chain management. delivery time be cut week, if have enough stock. allows quick equipment acquisitions well as gain competitive advantages.

Using the steel plate roller requires expertise and experience. Before operating the machine, the operator must understand the bending process, determine the material thickness, and set the roller alignment. The metal plate must be securely clamped in place, and the JUGAO sheet metal rollers must be adjusted to the desired radius. The rolling process should be done progressively, with periodic checks for accuracy and smoothness.

The steel plate roller is a significant investment for any metal fabrication business, and it requires regular maintenance and service to ensure its optimal performance. The manufacturer or supplier of the JUGAO sheet metal rolling should offer excellent customer service, including technical support, repair, and replacement of worn-out parts. The quality of the steel plate roller should also be top-notch, with durable components that can withstand heavy and continuous use.

The steel plate roller has numerous applications in various industries that require metal fabrication. In the construction industry, it's used to fabricate components such as bridges, tunnels, and pipelines. In the marine industry, JUGAO metal sheet roller is used to construct ship hulls, decks, and other structures. In the aerospace industry, it's used to make components for aircraft and spacecraft. In the automotive industry, it's used to produce parts such as exhaust pipes, mufflers, and fuel tanks.