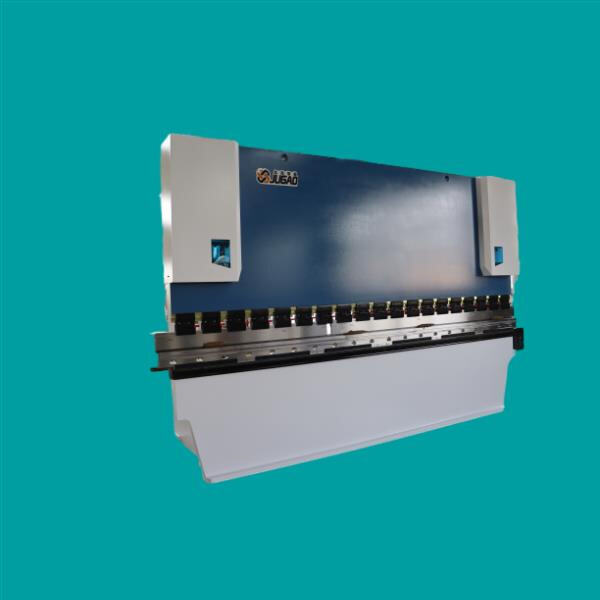

IntroductionThe press brake is a special type of machine in the forming industry. Bigger and which are somewhat specialized in terms of their work. Here is the little part that will help you to know more about what a press brake actually is;

Press Brakes are an extremely versatile machine for producing a diverse range of shapes in sheet metal. Heated and bent the metal with dies, which are special tools to form a varied shapes. Press brakes are good to make things such as brackets (small pieces that attach or connect thing, like) or panels which include groups of them used in builds and vehicles.

Press brakes are capable of bending metal but can also do an angle bend. They are right angle bends that allow parts to be fitted together correctly in very different projects. A press brake enables employees to form similar angles with the right bends and have everything fitness jointly just correctly.

Also capable of highly precise bends is a press brake. This is very important when parts need to be tight fitting like in automobile or machine. When a press brake is set up correctly the bend can come out very close to how it was designed. It is vital to maintain this level of accuracy since these components interact with one another.

Where press brakes are being used, it is demanding that the work to be done both fast and easy with utmost efficiency as well. Modern machines can be set up by workers with a computer for this press brake to make many parts in one shift. This kind of technology means they are able to produce parts more quickly and consistently, possibly even customizing them for the customer. Thus it is time as well energy saving for both the sides of the whole process.

If you are a weekend warrior or heavy work that requires the necessary fire and muscle, hydraulic press brakes may be best. This type of sheet metal bending machine can only perform industrial works and with the powerful machines easily bend deep into large sheets. This utilizes powerful hydraulic cylinders to press the metal into design you need, and is used for making parts that are tough & require a large force. Hence, all this makes the hydraulic press brakes a true champ for many of heavy dutiesifestyle.

Plus, new technology has made press brakes even better. With all these features and tools the engineers have made a way to provide utmost importance for manufacturers in producing their parts with faster means of improved precision, it is one part of a revolution. Take more sophisticated software control systems and improved tooling for instance, which allow operators to configure jobs with better speed, thereby operate in a far efficient manner. As a result, companies can start producing quality parts and saving money at the same time. As businesses, it is important that they compete and stay competitive just as the changing needs of our developing world — which new press brake machines can help to be done. 【Get Price】

press brake equipment Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.

press brake equipment aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.

press brake equipment brakes ideal complex bending operations high pressure accuracy laser cutting machines able deal range different materials efficient high-precision cutting capabilities; Rolling machines, thanks excellent forming capabilities effective production, satisfy needs large variety clients. Needs mass production. Pipe bending machines suitable various pipe processing due flexibility bending dependable performance. essentials industrial technology help manufacturing sector tackle various challenges efficiency, accuracy flexibility.

Quality Builds Trust. We committed sheet metal machinery assure every machine sell up industry standards. laser cutters rolling pipe bending machines, strive top-notch products ease worries.able press brake equipment quickly market needs utilizing efficient production supply-chain management. ample inventory, delivery times cut just week, allows rapid acquisition equipment gaining market advantage.