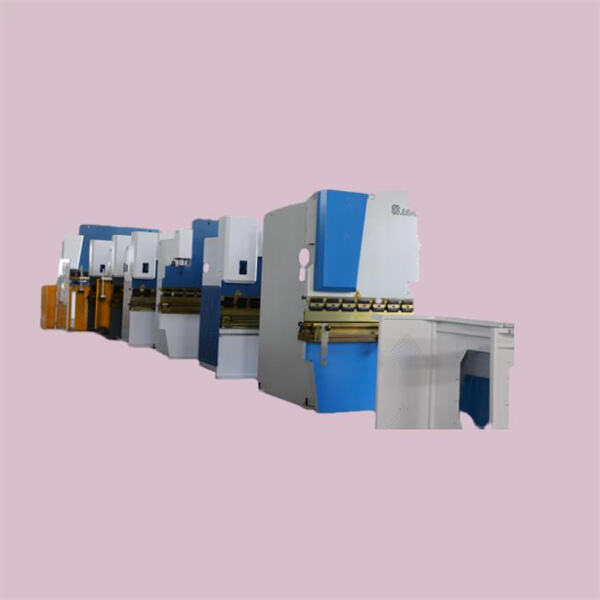

There is a machine called the press brake used to benders metal by pressing it with force. This machine works wonders for forming metal into various shapes. One such part of this machine is the press brake blade. A press brake blade resembles a lengthy piece of flat metal, and it is bent at one end. This blade makes the actual folding of metal happen.

Chances are a company with access to one of these machines is doing so because they need to bend large amounts amount of metal in short order and from the looks it, this thing can easily deliver. In Business time matters, the faster they work will help them to manufacture new products. A quality press brake blade will allow you to bend metal much more faster. The ideal press brake blade is manufactured using the sturdy material that wears out slowly to handle many times of use without breaking. When a business has good press brake blade, it will save them time they would otherwise be burning to make everything work in the right fashion.

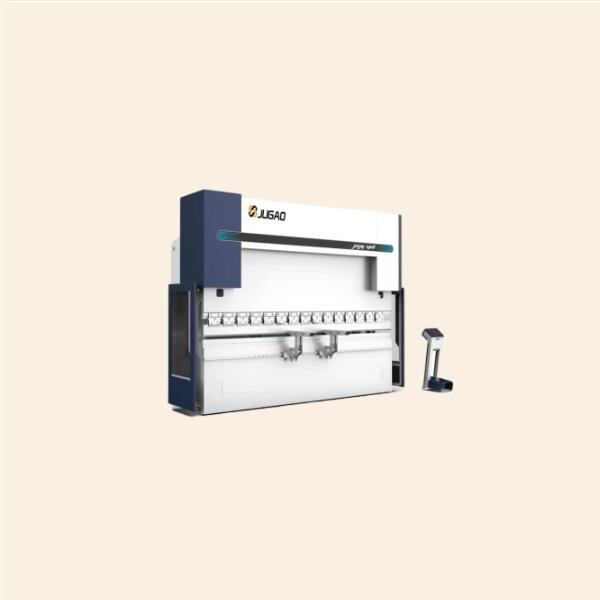

Bent for One of our clients is making some metal products, and they need every bend to be perfect. This basically means we want each bend to look identical and be super precise. One wrong bend can ruin the overall quality of your product. Enter: premium press brake bladeProfessional companies use what is referred to as a premium press-brake-blade in order for every bend to look good and meet the precision requirements, which can be achieved. These are top notch blades that enhance stability during the bending process and hence produce incredibly clean, smooth as well as precise bends. By using a high-end press brake blade, each bend will appear smooth and professional - which is very important as far as the quality of their products are concerned.

Press brake blades are made out of different types of steel. There are occasions in which one blade performs better at a job compared to another. A company must analyze the type of metal they are choosing to form and how thick this particular sheet is when selecting a press brake blade. These are key considerations for choosing a press brake blade. Selecting the wrong blade can mean they do not achieve their desired bends, and this in turn leads to dimension issues during production.

In the older days, bending metal was an extremely laborious affair that consumed a huge amount of physical effort and time. The metal needed to be folded into shapes that required heavy-duty strength. But now, the scenario has been totally changed. Bending metal nowadays is more of a walk in the park, thanks to high-quality press brake blades and modern technology. The fact that press brake blades are of good quality means they can yield better results in the form of an accurate metal bending and thus within a lower period. Technologically without a doubt we will see even better processing of metal in the future bending and forming.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Press brake blade.

Quality Builds Trust. believe sheet metal equipment make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines strive provide top-quality products ease anxiety customers.We respond rapidly market Press brake blade using effective supply chain production management. ample inventory, delivery time shortened one week, allows rapid acquisition equipment gaining advantage market.

Press brake blade efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.

Rolling Machines specialize metal sheet forming high-quality production. Press brake blade offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.