A hydraulic press brake is a tool bending apparatus which performs the functionality of wasted paper. It aids in creating a variety of angles and shapes with metal, making it an essential part for the need of constructing or manufacturing metals.

The press brake works by manipulating the power of hydraulic fluid which creates an intense force to bend metal. This force is what then allows the metal to be bent or formed exactly how it will need to occur in order for that particular job.

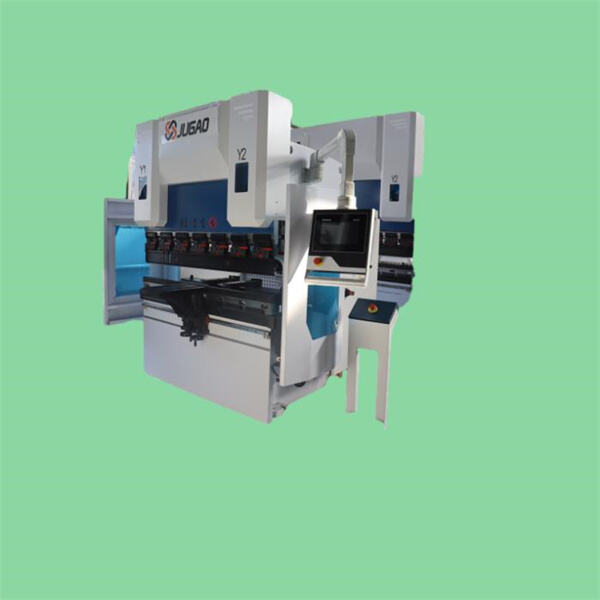

To put it simply, the press brake is comprised of different elements that work together to allow for sheet metal bending. These parts are the hydraulic fluid, cylinders, and ram. Pressure-build-up within the cylinders is created by hydraulic fluid, and this pressure then pushes down on the ram. This force is then imparted onto the metal by a ram to bend it accordingly.

Many considerations should be made when it comes to choosing the right hydraulic press brake for your application to deliver high-performance benefits. The first of these is examining the dimension of the machine. The machine should be big enough to fit the metal plates but not take up too much room in a workspace.

Additionally, the machine Tonnage meaning force of that can be applied is another important area to think about. The tonnage is critical, as it needs to match the metal plates that are being bent and shaped.

Secondly, the type of steel used is important. Different types of metals will have various efficiencies in different press brakes. Some machines have an upper hand in the bending of aluminum, while others are best utilized for steel shaping.

Metal Plates: Before being able to bend the plates, it is important that they are first cut out accurately and into the correct shape.

Press Brake Setup: During setting up, it is must that the press brake be correctly configured and safety measures are followed so as to prevent any kind of accidents.

Modifying the machine settings:It is important to adjust with regular intervals of time..... to give you a rough idea how would be when we place back metal plates

Bending Process Start: The means the machine is given power with the specified button or set of buttons, and making a constant pressure to fix at on place so that metal plates will start bending.

There is no doubt that hydraulic press brakes are highly relevant in the sphere of metal fabrication. These tools are part of a CNC press brake, which bends metal quickly and accurately to manufacture custom parts that would be hard to produce via manual processes.

recognize importance service sales Hydraulic press brake advancement. laser cutting machines, rolling machines, pipe bending machines, products, provide full range after-sales assistance includes Spanish after-sales services, ensure customers worry-free use. continue invest product development upgrade using latest technologies. helps meet evolving customer requirements keep top position market.

Press Brakes known reliability precision Hydraulic press brake various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.

Quality Hydraulic press brake Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

Press brakes suitable bending complex operations due high pressure precision; Laser cutting machines manage wide range materials thanks powerful high-precision cutting capabilities; Hydraulic press brake, thanks their exceptional forming capabilities efficient production, satisfy needs large variety clients. Pipe bending machines utilized mass production due flexibility stability. machines core latest industrial technology assist manufacturing industry meet challenges today efficiently quickly, precisely high degree flexibility.