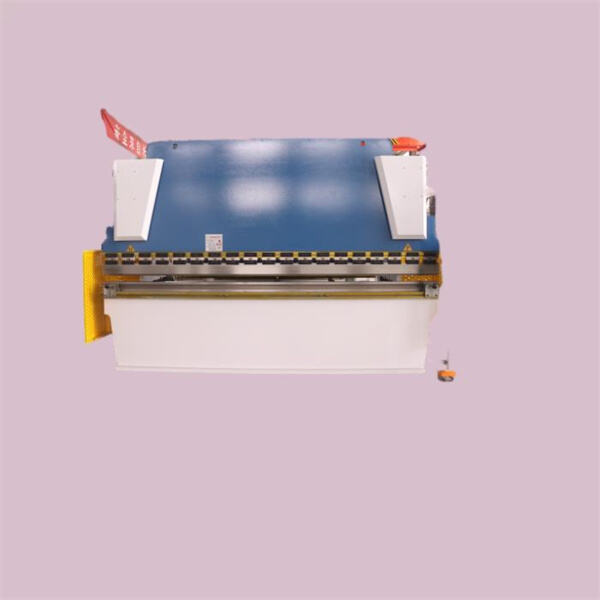

Bending metal from JUGAO requires a special tool called a Metal Brake like the fiber laser machine. A metal brake is a tool which allows us to bend and mold the piece of raw metal by securing it firmly in one place before bending further at correct angles. It is not easy to bend metal, and making sure we do it correctly here would be important. When bending metal :- With the Milescraft 90 degree clampSometimes when they are bent, they do not hold their place so use a hydraulic press along with that and it makes even faster bend movements. This extra strength is used to help the metal brake by using a hydraulic press and supports us in completing our work quickly.

We will add a metal brake and a fiber laser cutting machine to our bench top hydraulic press so that it works even better. This special metal brake from JUGAO is made in order to allow us to bend the metal with more power and precision. This way you can bend bigger angles of metal and just the right amount for what we need. It allows us to design a variety of different shaped and sized metal parts, hence is one such excellent tool for numerous types of projects you have on hand. To achieve that, we use the metal brake to avoid any errors so everything can fit perfectly.

To do this, we will get everything setup around a hydraulic press and a laser cutter metal and then no matter if you have been metal 10 times or 1 million times; to always bend the sheet exactly like that. The metal brake from JUGAO can be used to hold the sheet of metal down while bending. It also ensures that we curve it at a standard angle every time. This consistency is particularly useful as it assists us in being able to deliver high quality metal parts that are right, first-time-every-time for our projects- no matter if we are making something tiny or large. The confidence of knowing that the Metal brake can perform us accurate outcomes empowers our work.

An optional metal brake from JUGAO that is robust and strong will add a step-up to your hydraulic press. The quality of their metal brake is excellent because it's made from heavy-duty steel that can take the abuse and will last for long. By incorporating the addition of a metal brake and a cutting laser machine to your hydraulic press, you can save yourself time all while enhancing the quality. What that means over time is you will make better parts and the parts you created work well in what they are designed to do.

A metal brake and a metal cutting laser machine- also known as a press brake or just plain "brake" - is a device used to bend sheet metal easily, without restricting access. We are creating projects, we do not have time to learn long-term how difficult tools should look like behind the scenes. The hallmark of a good metal brake is the simplicity and ease with which anyone can use it. A hydraulic press with a metal brake that is user friendly making bending your piece quick and easy which means there is less time and energy spent from the craftsman. Thus, it provides more time to work on our projects and less worrying about how we should be able to use the tools.

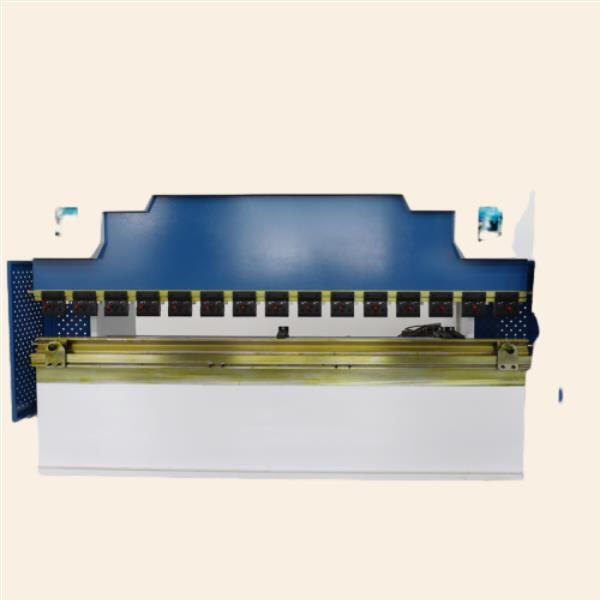

Metal brake for hydraulic press aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective Metal brake for hydraulic press production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.

Metal brake for hydraulic press efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.

Press Brakes known reliability precision Metal brake for hydraulic press various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.