Ever wonder how metal gets manipulated into intricate forms? It is amazing how one certain tool, a large metal brake in this matter also plays an important role to allow it all happen. It is a very strong machine that valuable in the world of metal fabrication, as it helps fabricators bend accurate shapes from sheets and plates to shape all various items starting from tough roofs to car particular parts.

This was a major turning point in the metal fab industry that led to things like building what we know call Press Brakes. Before its arrival, fabricators relied on hand-operated tools-such as hammers-to mold metal body surfaces by trial and error. But the large metal brake made this process of bending and shaping both quicker, as well as more precise.

The giant metal brake is nothing short of a game-changer in the world of metal fabrication, giving fabricators access to work on projects they once thought out of reach. Fabricators looking to handle thicker (say a quarter inch or more) metal sheets can do so effortlessly with this advanced technology. Such a machine can be so incredibly powerful and versatile.

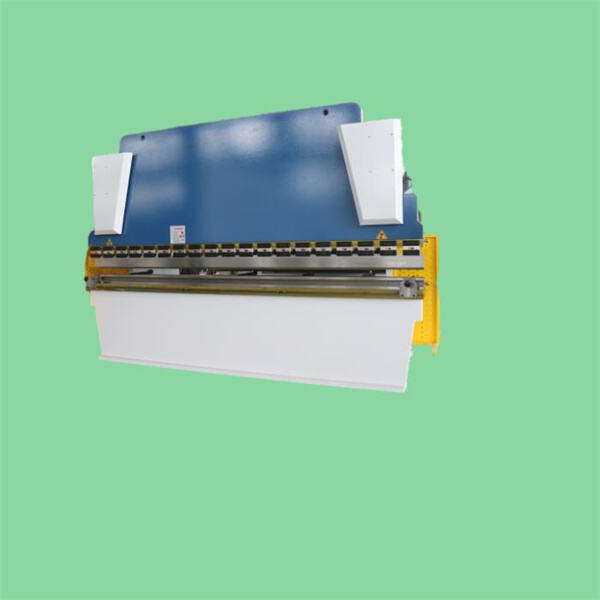

Using a large metal brake may sound complicated, but it's actually quite simple and very effective. The first one is, the metal sheet placed softly on a bed of the machine. The operator then chooses the metal bending angle they want and places it with tip touching brake clamping beam. As the press machine, applies an immense pressure on it slowly bend to that certain angle and shape into something totally different stuff.

The scale of metal brakes that are available to fabricators nowadays has also unlocked a roster of complicated projects once thought cartoons; not practical due simply their complexity. They can now easily make rounded metal parts (e.g., car fenders) and detailed motifs in sheet or plate metals roofs & sculptures. Whatever the project, a big metal brake is about as elemental an essential for any metal fabricator.

In Conclusion, The Big Metal Bending Brake: An Irreplaceable And Game-changer In Sheet Metal Fabrication. Changing the way in which metal forms are shaped, it made virtually any form-process easy to achieve from a fabricator standpoint. This technology has made it so that the ways in which you can shape and design metals are virtually infinite.

Large metal brake Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.

Quality Builds Trust: Large metal brake sheet metal machines meticulously supervise quality control ensure machine is line industry standards. strive provide highest quality products customers. laser cutters press brakes, pipe bending well as rolling machines.Rapid Market Response: leveraging efficient production supply chain management, we able quickly meet market demands. ample inventory, delivery time reduced week, enabling prompt equipment acquisition market advantage.

precision efficiency, Large metal brake cutting machines able deal range materials. Rolling machines thanks amazing forming capabilities high-efficiency production, meet requirements many clients. Pipe bending machines employed mass production thanks flexibility stability. products essence industrial technology, enable manufacturing sector respond different challenges ensuring accuracy, efficiency flexibility.

know importance service sales RD Large metal brake. laser cutting machines, rolling machines pipe bending machinery many products, offer entire range after-sales assistance services, Spanish after-sales service make sure customers enjoy hassle-free experience. continue invest product development upgrade technology innovation. helps adapt changing needs customers keep leadership position marketplace.