TRANSFORM YOUR MANUFACTURING PROCESS THROUGH THE AID OF AN ELECTRIC METAL BRAKE

An electric metal brake is a unique device as compared to all other tools in the world of manufacturing, and that has brought huge technological changes. This advancement plays a significant part in enabling factories to produce goods faster, efficiently and cost-effectively. Find out more in this article that reviews the many great things you get when a mechanical brake is replaced by an electric metal brake.

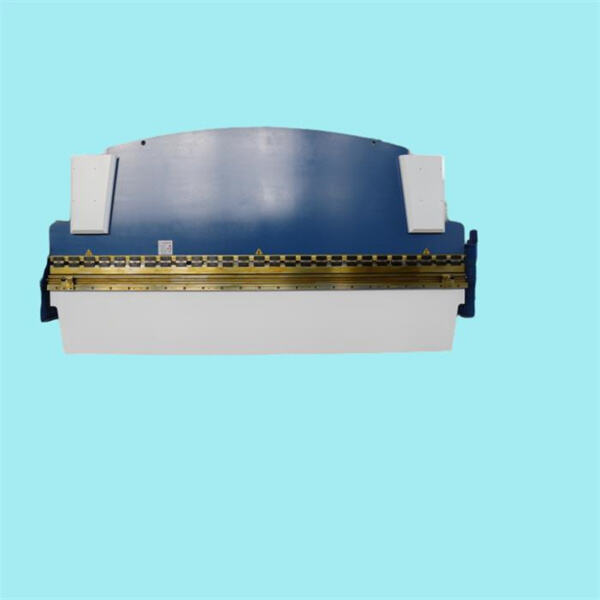

The creation of electric metal brake technology has changed the whole manufacturing scenario. This enables manufacturing factories to produce metal sheets faster and more easily than ever. Electric metal brakes are some of the most versatile tools offering what appears to be nearly magical ability. These cutting-edge methods create accurate metal sheet bends much faster and with less preparation than traditional manufacturing enterprises. This not only saves the priceless time and resources but also directly results into cost-effectiveness.

One of the most effective and accurate tools available to manufacturers is arguably metal brakes, such as electric ones. Arguably the biggest benefit is in reducing time to complete. Where traditional bending methods might have taken hours to get the job done, with this machine getthe bending process will be over in a matter of seconds. This time savings is important for factories looking to increase production rates while reducing cycle times. On top of that, those are said to use lower levels of electrical power than many alternatives and therefore give fewer emissions.

Electric metal brakes also have over conventional benders; they work great tools for manufacturing applications. We will cover some of the most significant benefits they have for you in this Posts.

Accuracy - Computer-controlled automation allows the electric metal brake to bend than any amount of precision.

Efficiency: These tools are designed to give accurates bends in rows, sheets or angles of metal material within short time intervals thus lessening the production process cost and labor duration.

However, electric metal brakes are quite capable of processing various types and thicknesses of sheet materials.

Precision: Their ability to form intricate shapes improves product quality and consistency.

Electric Metal Brake technology offers control and consistency

Consistency is critical in the manufacturing space. Manufacturers can ensure that metal sheets are bent to precise specifications every time using an electric metal brake. The use of automation and sensor technology controlled by the computer allows parts production in large series to be carried out uniformly. It helps to provide a certain level of homogeneity in the various materials that possess similar composition and properties, which can account for increased efficiency during different industrial endeavors.

Electric metal brake system is a fundamental part of modern production, which has streamlined the mass produced process. This modern technology, alongside being accurate and fast, is extremely reliable as well-critical for the production of higher-quality final goods. With continued innovations and technological growth, metal brakes have turned into a highly efficient machine that is not only powerful but also very user-friendly.

Ultimately, this electric metal brake is a disruptive force in manufacturing! Definitely, these time-saving, efficiency-enhancing and product quality-improving tools are a future of manufacturing processes that every manufacturer wants to have in their kitty! There are so many things electric metal brakes can do that one or two will have a hard time with, and the technology has clear advantages over traditional linear motion systems for precision metal forming applications; these just scratch the surface.

Press Brakes renowned accuracy efficiency ideal variety processes metal sheets; Laser Cutting Machines achieve high-speed electric metal brake cutting order meet complex pattern requirements; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability order improve production effectiveness quality products.

recognize importance service sales electric metal brake advancement. laser cutting machines, rolling machines, pipe bending machines, products, provide full range after-sales assistance includes Spanish after-sales services, ensure customers worry-free use. continue invest product development upgrade using latest technologies. helps meet evolving customer requirements keep top position market.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle electric metal brake materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.

Quality Builds Trust. believe sheet metal equipment make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines strive provide top-quality products ease anxiety customers.We respond rapidly market electric metal brake using effective supply chain production management. ample inventory, delivery time shortened one week, allows rapid acquisition equipment gaining advantage market.