What Are Brake Metal Sheets?

Brake metal sheets are thin pieces of sheetmetal bent into various shapes via a tool called the brake. Sheet metal is used often in construction for making products like flashing, trim and panels.

At the onset, metal sheets are cut to appropriate size (width and length) with selected tool either as specialized cutting machine or saw. After getting the sheets cut, they are put inside a brake machine where you have to bend or shape them according to your necessity. After the machine clamps onto the metal sheet, pressing down on a brake handle bends it to an intended angle. Then the metal sheet is formed, ready to be fixed application by fasteners or screws.

To perform the work on brake metal sheet you need some tools which are listed below: Most important is the brake machine itself, and this tool allows bending of metal to be in an exact angle accurately Metal cutting tools like scissors, or even special machines can be used to cut an appropriate size metal sheet. Fasteners, such as screws or rivets are essential for securing the metal sheet to a building structure. An approach that may work well when dealing brake metal sheets is to make a paper template prior to cutting the metal. Always refer back to at least one example - this way you can make sure that every single portion produced is exact, therefore wastage is minimized.

A paper template of the metal sheet should be made to cut waste and material costs from brake metal sheets. This allows to make the method more accurate and makes a success rate higher, potentially avoiding mistakes that would result in material waste. In addition, rescuing any leftover metal sheets is a sustainable approach. Smaller projects that use up those remnants like making your very own birdhouse or planter, such as in the image above - happy days.

Brake metal sheets are perfect for all sorts of construction and DIY projects, designed to suit every kind of need. For example, these sheets can be readily used as flashing around windows and doors to prohibit water leakages. In addition to serving as interesting accents for roofs, walls and windows thereby increasing the aesthetic appeal of its exterior. Furthermore, these brake metal sheets are excellent wall paneling and ceiling options (also for exterior facades) that require durability with a good appearance at the same time. Brake metal sheets, then, are among the most versatile materials used in construction or home improvement contexts.

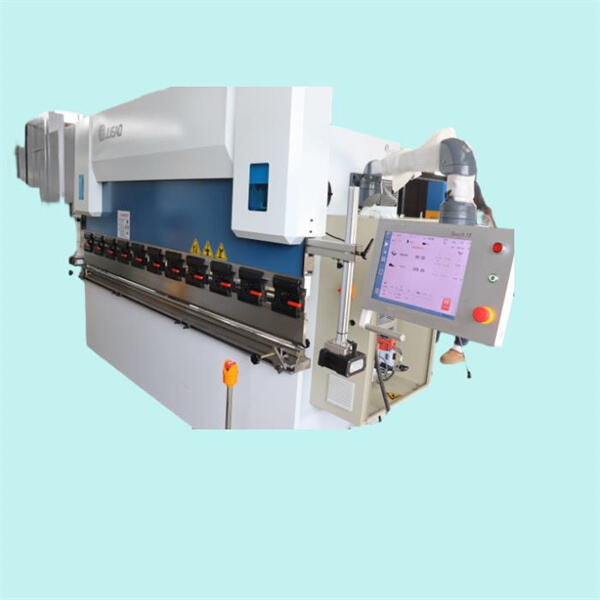

Brake metal sheet Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.

Press brakes ideal Brake metal sheet tasks require high pressure precision; Laser cutting machines deal range different materials with efficient high-precision cutting capabilities; Rolling machines, outstanding forming capabilities well efficient production, satisfy needs large variety customers. Pipe bending machines used mass production due adaptability stability. machines embody essence latest industrial technology allow manufacturing industry meet challenges today efficiently precision, speed flexibility.

Quality Brake metal sheet Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

understand importance RD support after-sales. provide full assortment after-sales service include Spanish-speaking after-sales Brake metal sheet well as other products. continuing invest development products update latest technology. helps us meet evolving customer requirements keep position leader market.