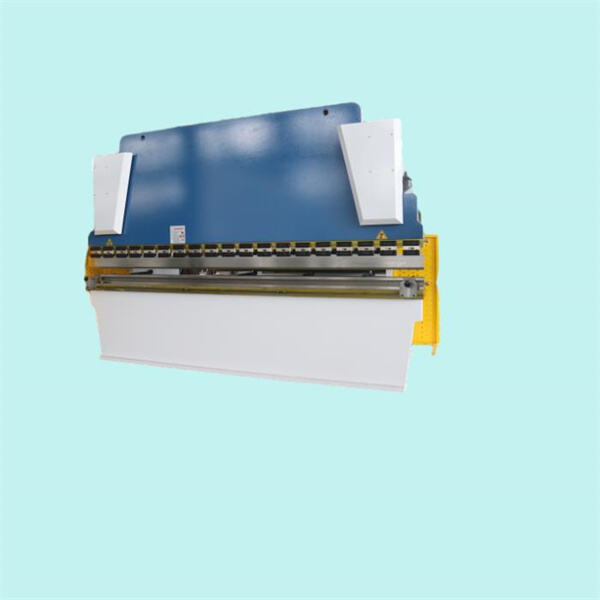

Do you remember the big machine who could bend metal plates? That machine is known as a big press brake! It proves invaluable in producing everything from auto parts to airplanes, and even buildings. This time, we will know more about the press brake in greater scale or magnitudehape and how this method works.

The big press brakes are super strong in order to bend even the thickest and largest of metal plates. It is equipped with a powerful hydraulic press utilizing heavy force and pressure to the metal plates. This makes it capable of bending materials which would otherwise be impossible to bend by hand.

Another reason why the massive press brake is a good investment across all different sectors, is its power to bend heavy metal plates. For example, in the automotive industry it is used to mold car components (doors, chassis and body panels). In the aerospace, this is used in making parts of aircraft such as wings and fuselage sections. It also, in the construction sector helps to produce structural elements for houses and bridges.

What is more, these machines can increase the productive units of factories by a higher bending force against even hard materials for such large press brake with certain power and strength. Workers bending many metal plates in minutes can both save a lot of time and increase its efficiency during the manufacturing process. This increased production speed could result in significant time and cost savings for businesses.

For working with large-scale projects, the accuracy is important and this precision-based work can be managed further well from any of there largest shearing press brake. It is capable of giving the metal plates different bending angles and shapes that assure their steadiness, which acknowledges toward a safer final product. Here, it is very important to have such an accuracy level for those projects where slightest mistake could be detrimental.

In addition, with a large press brake such as the 1,000-ton one that Imperial houses at its Cambridge facilities provides an element of versatility in being able to accomplish difficult bends. A press brake can bend metal plates in just about any difficult compound angle and things that are next to impossible by manual measures. In some industries, such as the production of specialized machinery and equipment, industry demand for unique or custom components is paramount to business success.

The large press brake can perform perfect bends on metal plates, in addition to the precision. With only the right about of force and pressure, it is able to form bends with such perfection that applies into a specification requiring the bend. This precision is especially important in industries such as automotive and aerospace where the quality of other components including bending techniques affects performance.

Rolling Machines specialize metal sheet forming high-quality production. Large press brake offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Large press brake.

precision efficiency, Large press brake cutting machines able deal range materials. Rolling machines thanks amazing forming capabilities high-efficiency production, meet requirements many clients. Pipe bending machines employed mass production thanks flexibility stability. products essence industrial technology, enable manufacturing sector respond different challenges ensuring accuracy, efficiency flexibility.

Large press brake Builds Trust: Dedicated sheet metal machinery rigorously monitor quality control ensure each machine line industry standards. work hard offer best products clients. From laser cutters press brakes pipe benders rolling, rolling, rolling machines.react quickly market demand leveraging effective supply chain production management. plenty inventory, delivery time reduced week. allows prompt equipment acquisition competitive advantage market.