To be metalworkers wanting to cut, bend metal.. If yes then a shear press brake is exactly what you are looking for! This machine will make it easier and much faster for you to work. In this post, we cover the concept of shearing press brakes and its operation to explain why it is a vital apparatus for metalworkers.

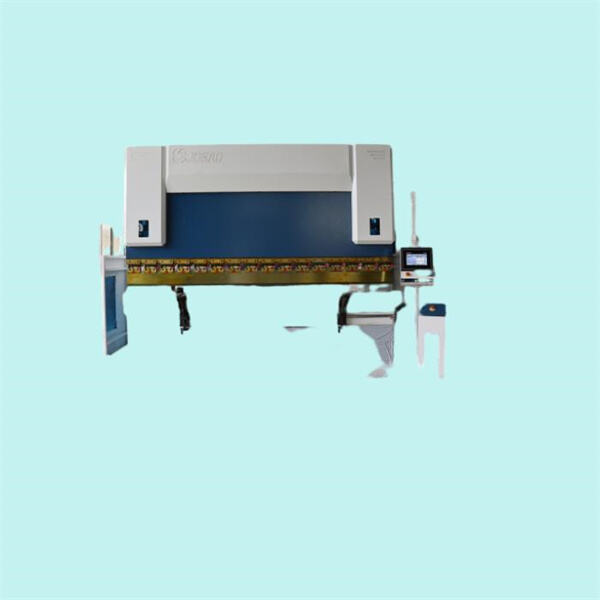

You may now have an idea that this shear press brake is a kind of machine not commonly dug. This machine helps you cut and bend the metal sheets as per your desired shapes and sizes. There are two main components which include the shear and brake. It is the part that cuts metal sheets to size and forms angles, be it being cut from this shear or broken at different points. These two sections together made it much easier for the workers of metal to mold their material into many shapes and configurations. This machine is a boon and list the two most important things in one handy device.

A great pro about shear press brakes transcend from how strong they are. For those working more extensively with thicker materials, a good cutting machine is still required due to the fact that these machines can handle metal sheets relatively easy and light. They also have exact cuts and bends. Because of this, you will get your complete piece exactly as desired. A press brake with a shear means beautiful, perfect cuts and bends! The precision is great for projects where they must all fit together just right.

Shear press brakes are not only powerful, it is very efficient as well. Such machines can cut and bend large quantities of metal in one go, they do so very fast as well on a consistent basis. It also helps to get more of the work done in less span of time. A shear press brake allows you to make a complete lot even more items throughout the training course of time. Since they are extremely accurate, the error rate and waste of materials is reduced greatly. This will allow you to work, no worries about errors! Efficiency is essential in metalworking, especially when time constrains and customer satisfaction are important to your business.

If you are looking to increase productivity in your metalworking, buy Shea Press Brake. You will be able to produce virtually any shape or design with this machine. With a shear press brake, you can make one-off parts for your customers or crank out many identical pieces in quick time. This allows you to start taking on bigger clients or larger projects and handle the pressure more easily. A shear press brake is a necessary tool that can help you greatly in this matter and allow for any kind of metalworking.

I believe that every craftsman of the metalworker has a desire to make products high-quality and which will like at our client. This is where a shear press brake comes to the rescue. This way you are guaranteed there is not any room for error, and these machines have the power to make all of those cuts an bends with precision. If you are inexperienced in using a shear press brake or in metalworking generally, purchasing one is actually a good decision because this will save your job. This can add a lot of value to your deliverable making it beautiful attractive for the client.

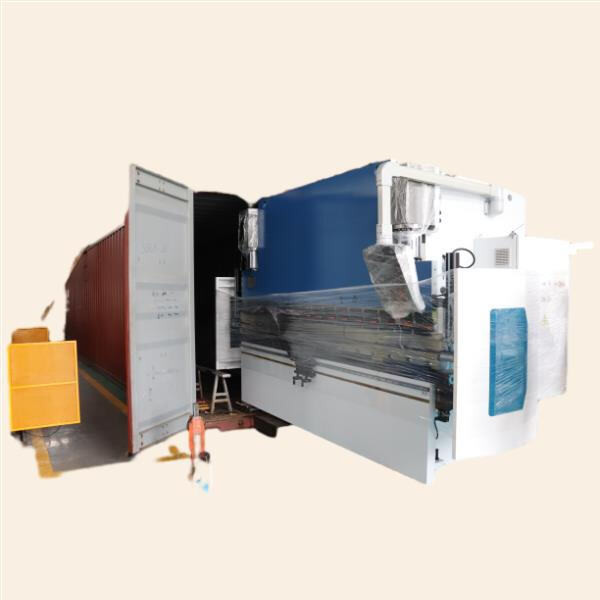

recognize importance service sales shear press brake advancement. laser cutting machines, rolling machines, pipe bending machines, products, provide full range after-sales assistance includes Spanish after-sales services, ensure customers worry-free use. continue invest product development upgrade using latest technologies. helps meet evolving customer requirements keep top position market.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease anxiety customers. can respond shear press brake market demand leveraging efficient production supply chain management. delivery time be cut week, if have enough stock. allows quick equipment acquisitions well as gain competitive advantages.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle shear press brake materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.

Press Brakes recognized efficiency accuracy suitable various metal sheet processing. Laser Cutting Machines achieve high-speed, high-precision cutting meets shear press brake complicated patterns. Rolling Machines specialized forming metal sheets ensure production quality; Pipe Bending Machines offers flexible pipe bend solutions. product range focused accuracy, efficiency, stability order improve effectiveness quality products.