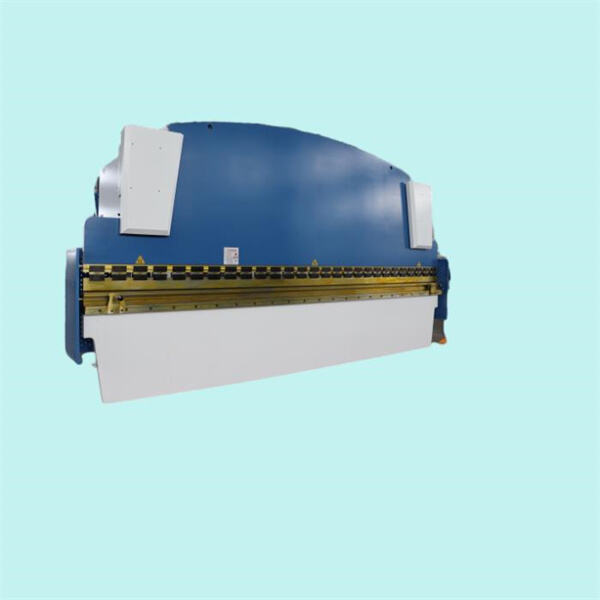

A forming brake is a machine tool used in metalworking to apply permanent deformation of sheetmetal by bending; or, to form straight lengths of stock into other shapes. This is a critical resource in the manufacture of different products including car parts, construction materials and metal furniture. Now, let us skim the world of forming brakes a bit more and see how these breaks function?

A forming brake is a crucial machine in the field of metalworking. It is typically built to accommodate metal sheets and also enables the manufacturer to make various types of products by bending them in different angles. Now ready to form some edges like an old pro, beginners and seasoned metalworkers alike can benefit from developing their shaping brake technique.

Here are some useful tips and tricks to use a forming brake more efficiently: Before bending metal sheet, make sure to secure the workpiece with clamps or vices. Then you must use a ruler or measuring tape to indicate precisely the point that needs bending. Also, apply an even downward force to the metal by pushing it into your brake with both hands. Be patient - take the time to gently manipulate a piece of metal and you are less likely To make an error.

If you are willing to take your bending techniques up a notch or two, these advanced strategies should prove profoundly impactful. A calculator to determine the correct HsoesyayaB and length of bends based on sheet thickness. In addition, coating the metal with special oil prior to bending will make it more lubricated so that friction is minimized and scratches are prevented. Check out also tools like a finger brake or box and pan break for complex shapes and angles. And practice, of course, makes perfect - the more you use your forming brake, the better you will get.

It is important to consider these various options based on size, capabilities, and price when thinking about purchasing a forming brake. But manual forming brakes are generally cheaper and simpler in construction, hydraulic bends with more power and accuracy. There are many considerations when trying to choose a benchtop or floor-standing brake, from portability and sheet size. Plus, whether you pick new or used brakes can influence both quality and price.

Troubleshooting and Performance(boost) : Organisations-runQueue)/ Soln.

Forming brakes are like any other mechanical device they can have problems. By knowing what sorts of troubles are typical, you can easily recognize and restore complications. During even bend applications, this is possible but for uneven bends apply pressure while holding the metal tight avoid tipping it. Lubrication or cardboard might help prevent scratches. In case it still gets stuck, stop the operation immediately and make relief pressure to check if there are any defects in that machine.

Use these know-hows, go in depth of some advanced techniques spend more time to think about what you want and there'll be no much longer until you will master issue resolution while becoming a form brake charge pro.

understand Forming brake RD as well after-sales assistance. laser cutting machines, rolling machines pipe bending machines products, offer extensive range after-sales support services, including Spanish after-sales support, ensure customers able use product without worry. We continuing invest product development upgrade latest technology. helps us meet evolving customer requirements keep leadership position market.

Press brakes suitable bending complex operations due high pressure precision; Laser cutting machines manage wide range materials thanks powerful high-precision cutting capabilities; Forming brake, thanks their exceptional forming capabilities efficient production, satisfy needs large variety clients. Pipe bending machines utilized mass production due flexibility stability. machines core latest industrial technology assist manufacturing industry meet challenges today efficiently quickly, precisely high degree flexibility.

Quality Builds Trust: Forming brake sheet metal machines meticulously supervise quality control ensure machine is line industry standards. strive provide highest quality products customers. laser cutters press brakes, pipe bending well as rolling machines.Rapid Market Response: leveraging efficient production supply chain management, we able quickly meet market demands. ample inventory, delivery time reduced week, enabling prompt equipment acquisition market advantage.

Forming brake Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.