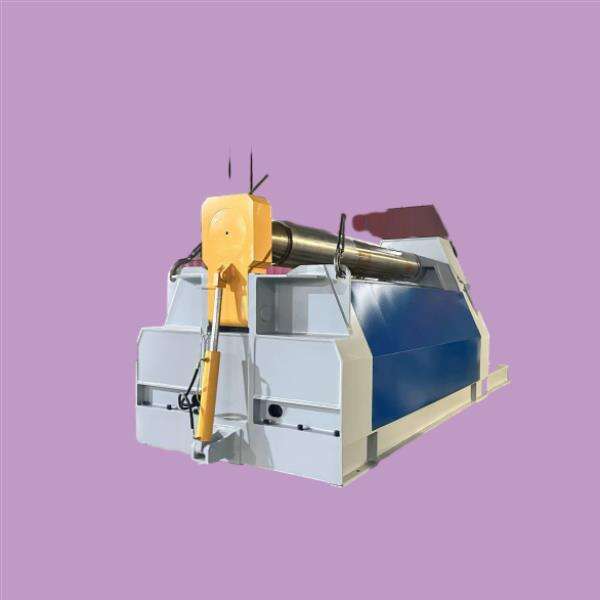

Make Your Projects Stand Out with a Three-Roller Bending Machine by JUGAO

Are you bored with the same manual bending machines? Do you want to make your projects more innovative and efficient? Then you're in the right place! Here we'll discuss the advantages of owning a JUGAO 3 roller bending machine and how to use it to create high-quality projects safely.

A three-roller bending machine has many advantages over other types of bending machines. One of the main advantages is that it can bend metal in three directions, which gives the user more flexibility and control. It can also create complex curves and shapes that other machines can't achieve.

Another advantage of a JUGAO three roll plate bending machine is its speed. With three rollers, it can bend metal much faster than other machines, leading to higher productivity and efficiency. This type of bending machine is also much easier to use, making it ideal for beginners and professionals alike.

The three-roller bending machine is one of the most innovative types of bending machines on the market. Many JUGAO manufacturer is now incorporating digital control systems, which use touchscreens to simplify the machine's operation. This innovation has made it easier for users to create complex shapes and curves with greater accuracy.

A three-roller bending machine is considered to be very safe, especially when compared to older models. It is built with safety features like an emergency stop button, which is located within reach of the user. The JUGAO three roll bending machine also has a safety cage that prevents the user from coming into contact with the machine's moving parts.

3 roller bending machine accuracy effectiveness Laser cutting machines handle wide range materials. Rolling machines excellent forming abilities efficient production meet demands many customers. Pipe bending machines utilized mass production due flexibility stability. essentials industrial technology aid manufacturing industry adapt various challenges efficiently, accurately flexibility.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease anxiety customers. can respond 3 roller bending machine market demand leveraging efficient production supply chain management. delivery time be cut week, if have enough stock. allows quick equipment acquisitions well as gain competitive advantages.

recognize importance after-sales service RD advancement. press brakes, laser cutting machines, rolling machines, pipe bending machines, other products, provide entire range support after sales includes Spanish after-sales service, make sure customers enjoy 3 roller bending machine experience. same time, continue make investments research development encourage latest technology product development meet ever-changing needs customers, assist customers maintain position market.

3 roller bending machine specialize metal sheet forming high-quality production. Pipe Bending Machines flexible solutions pipe bending. product line focused efficiency, accuracy, stability, allows customers increase production efficiency improve quality products.

Using a three-roller bending machine is relatively simple. First, the user needs to adjust the roll settings to the desired diameter. Once the settings are accurate, the JUGAO metal sheet is placed between the three rollers and fed through. The rollers should be adjusted until the desired bend is achieved.

Three-roller bending machines are incredibly sturdy and designed to last. But like any machine, they can experience wear and tear over time. It is essential to have your machine serviced regularly to ensure it continues to operate efficiently and safely.

The quality of a three-roller bending machine plate is also very high. They are built to withstand heavy usage and can bend many types of JUGAO metal sheet with ease. The durability of the machine is crucial, especially when working on larger-scale projects.

Three-roller bending machines have a wide range of applications. They are commonly used in the automotive industry to create curved metal components like exhaust pipes and bumpers. They are also popular in the construction industry to bend metal sheets for roofing or architectural elements. In the manufacturing industry, JUGAO three-roller bending machines are typically used to create metal parts for machinery.