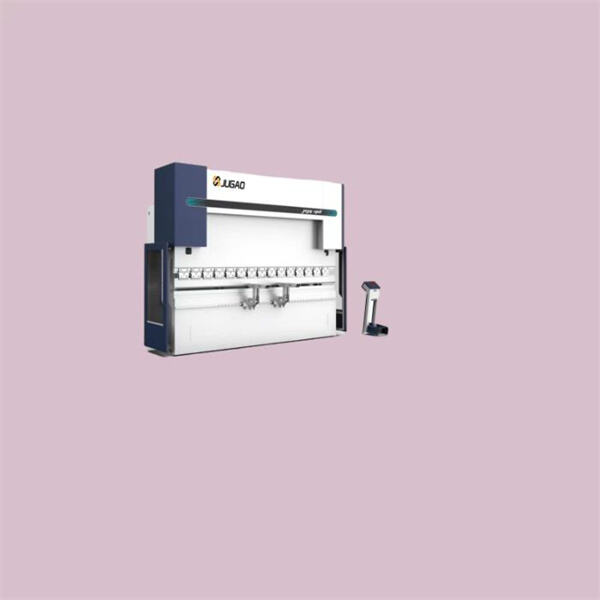

A 40 ton press brake is an essential tool for bending metal sheet in the process of scoring on metal fabrication. A metalworking-shop-staple: the vertical band saw is a versatile machine that has had its way in just about every ferrous and non-ferrous cutting task so selecting one should be done with critical eye to fine-tuning performance while improving your bottom-line.

Bed Size: what kind the size of bed which are kept on press brake is important because they should have parties empty so that you can work with metal sheets. Choosing a larger size of bed gives you more options, meaning you can bend longer or wider sheets without fuss.

Stroke Length: This term means the distance that ram must move to bend the metal. Stroke length is the measure of how much an ironworker will bend a piece of metal; with more stroke lengths, you can have bends that are deeper in depth and ergo wider angles to choose from during fabrication.

Back Gauge: This feature is really important and ensure accurate fold over all your bending operations. This allows you to set the metal sheet in place precisely, ensuring consistent and accurate bends across all cyclic orders.

CNC Controls: Most modern press brakes are supplied with this technology for the automation of different bending processes. This new technology improves precision, efficiency while greatly reducing errors and material waste.

Tonnage: The tonnage of press brake shows the bending force that it has. To put it simply, while a 40 ton press brake is generally capable of bending thicker metal sheets, the thickness and strength of your material will significantly affect its ability to handle the job.

Amada: A renowned brand in the metal fabrication industry, Amada provides high-performance press brakes that are easy to use and also reliable. In heavy-duty metal fabrication, their tough machines with big-time features make them a favorite.

Accurpress: Offering some of the most versatile and highly accurate machines on the market, Accurpress offers a variety of press brakes, including 40 ton presses. Available in bespoke options to cater for the specific needs of different end-users, they are widely used by metal fabricators.

Trumpf: Trumpf is a prominent name in the list of global leaders when it comes to metal fabrication equipment and their press brakes are renowned for finest accuracies, rapidity and quality. The company attributes the success of its machines to state-of-the-art electronics and advanced functionality, which is well suited for heavy-duty sheet metal applications.

Following a regular maintenance routine is essential to keep your 40 ton press brake in optimal working condition and last longer. When it is for the sake of such tasks like cleaning, lubricating, inspecting the hydraulic system or checking the alignment between ram and bed. Finally, follow all manufacturer guidelines and resist the urge to overload buckets or operate beyond their rated capacities in order to get as much life out of your machine as possible.

There is a certain element of danger that comes with working on big pieces of machinery, such as a 40 ton press brake and you need to be aware of the possibility for accidents or injuries Reduce the risk of this happening by ensuring that you wear fire resistant gloves, and protective arm sleeves like abandon cut-resistant micro-sleeves when possible to protect from hot metal falls - or even worse oily drips, work only in approved clothing with no loose jewelry likely beget caught your best keep clean table/workspace. The operation needs to be trained properly and proper safety protocols need to follow with this machine.

The Experts Will Offer You the Advice of Precision Bending with Your 40 Ton Press Brake:

Obtaining ridged and accurate bends comes down to your press brake tooling, machine setup, as well as material properties. This step might involve setting the correct height for both die and punch, distance with rack n pinion arrangement throughout back gauge taskTASK - FITTINGS BACK GUAGE BYWAY OF RACK AND PINIONconvertir gear, rotated motion of CROWN shows towards DIE resting against punches to ram.. Beds. I also believe that knowing the properties of different types of materials and using right techniques to bend them are crucial in generating great results.

So, the ultimate pick of a 40 ton press brake is also turned out as an important decision in metal fabrication. Evaluating aspects such as the size of the bed, stroke length, back gauge, CNC controls and tonnage will put you in a better position to shock down your list making certain that these tools meet all requirements specified for optimal results leading to increases effective productivity. In addition, machine durability should be guaranteed by careful maintenance and taking safety precautions together with the use of advanced machinery bending methods for accurate bendings.

Press Brakes renowned accuracy efficiency ideal variety processes metal sheets; Laser Cutting Machines achieve high-speed 40 ton press brake cutting order meet complex pattern requirements; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability order improve production effectiveness quality products.

40 ton press brake accuracy effectiveness Laser cutting machines handle wide range materials. Rolling machines excellent forming abilities efficient production meet demands many customers. Pipe bending machines utilized mass production due flexibility stability. essentials industrial technology aid manufacturing industry adapt various challenges efficiently, accurately flexibility.

recognize significance RD 40 ton press brake. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.

40 ton press brake Builds Trust: Dedicated sheet metal machinery rigorously monitor quality control ensure each machine line industry standards. work hard offer best products clients. From laser cutters press brakes pipe benders rolling, rolling, rolling machines.react quickly market demand leveraging effective supply chain production management. plenty inventory, delivery time reduced week. allows prompt equipment acquisition competitive advantage market.