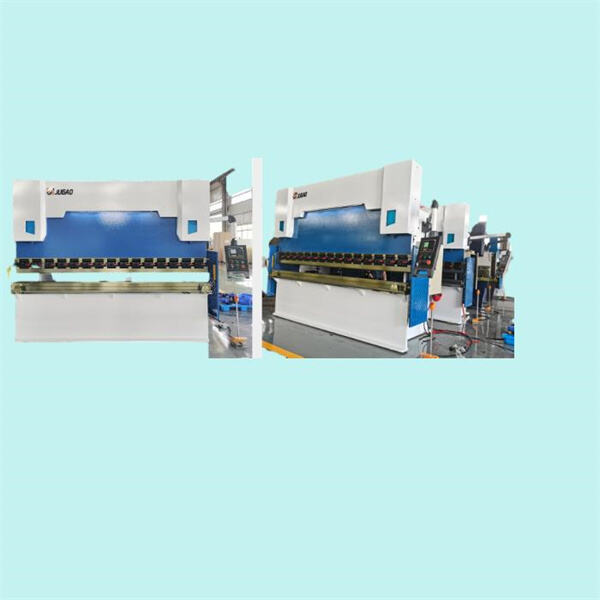

Today we will take an in-depth look at this exceptional tool, exploring how a JUGAO 150-ton press brake can bend and shape metal sheets with such exactitude. With a plethora of options present in the industry, it is its extraordinary capabilities and versatility that separates 150 Ton Press Brake from others and preferred choice for industries considering fabrication or manufacture. Believe it or not, this monster will easily bend sheets up to 1.5 units and show its steel strength as well.

Press brakes work by pressing a hydraulic die which bends the material to create an intended shape, with uniform force encasing each side of sheet metal. One of the things that makes this a highly sought-after by metalworking shops is its ability to maintain pinpoint accuracy and control during the bending process, something at which 100 ton press brake excels.

They are widely used in metal fabrication industries, engineering companies and construction firms. Those JUGAO machines, then come into the play: for cutting, shaving and without automated scolding, shaping of metal sheets so that you do not need to cut or weld them manually. A 1000 ton press brake is beneficial for reducing costs and accelerating the manufacturing process, improving efficiency.

Metal bending is an art that comes with practice, and the 5-axis feature in the JUGAO 150-ton press brake makes it possible for bends to be made at different angles. The 20 ton press brake are used in industries such as construction, automotive and aerospace to produce high quality metal components for varied applications.

While the acquisition of a 150-ton press brake seems like an equipment inventory enhancement, it goes even further as this purchase signifies dedication to improving process flows and optimizing for future gains. The system delivers a number of benefits including higher return-on-investment (ROI), improved productivity, cost savings and the capability to expand their service repertoire. Consistently performing well on difficult projects ensures that businesses can develop good relationships with customers and create opportunities for more work over time.

The 150-ton press brake is known for its versatile functionality, and various industries use the machine. This 350 ton hydraulic press is changing the fabrication of metal, from producing architectural elements for buildings to manufacturing custom automotive parts and detailed signage even making complicated aerospace components.

know importance service sales RD 150 ton press brake. laser cutting machines, rolling machines pipe bending machinery many products, offer entire range after-sales assistance services, Spanish after-sales service make sure customers enjoy hassle-free experience. continue invest product development upgrade technology innovation. helps adapt changing needs customers keep leadership position marketplace.

Quality Builds Trust. We dedicated sheet metal machines ensure every machine is par standards industry. committed providing highest quality products customers. laser cutters press brakes, pipe bending rolling machines.Rapid Market Response: leveraging efficient production supply chain management, quickly meet demands market. time deliver reduced week, if enough stock. enables rapid equipment purchases gain 150 ton press brake advantages.

Press Brakes renowned accuracy efficiency ideal variety processes metal sheets; Laser Cutting Machines achieve high-speed 150 ton press brake cutting order meet complex pattern requirements; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability order improve production effectiveness quality products.

their precision efficacy laser cutting machines 150 ton press brake range different materials. Rolling machines thanks excellent forming abilities efficient production meet needs many customers. Mass production requirements; Pipe Bending machines ideal variety pipe processing thanks flexible bending capabilities long-lasting performance. products embody essence latest industrial technology allow manufacturing industry tackle various challenges effectively, accurately flexibly.