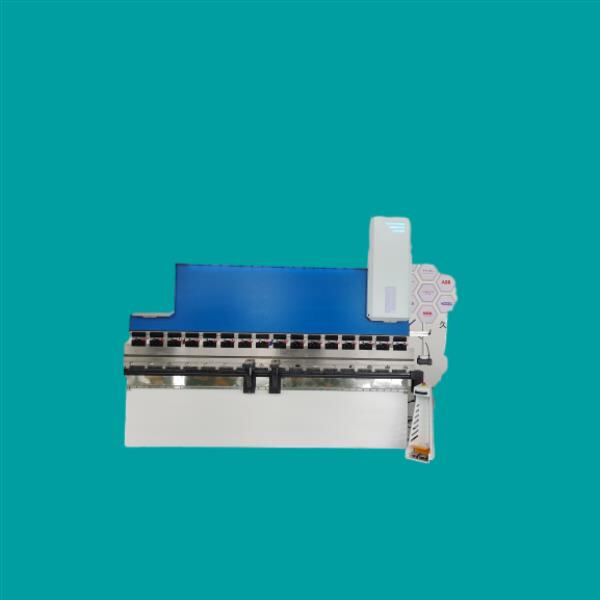

Have you even heard of pneumatic press brake? A type of machine through which metal is broken and formed. Think of it as a big machine that can press down on metals so they get formed. By air pressure, this causes the metal plate to be pushed down so that it will bend into angle based on what degree you input. If you are into making things in a factory, buildng buildings at construction sites or want to do some serious metalwork with professional grade machinery, then chances are that the pneumatic press brakes can be found anywhere. This is why they are important tools as they assist in the creation of various types of metal designs that add a finishing touch to every project.

A major advantage of pneumatic press brakes is they are extremely precise. That way, you can get a perfect square all around.QRectangles means shapes and angle go where they are supposed to. By this, exact dimensions: they have ensured that the openpowder deck with sliding elements and closed eco system of Metal swift traps fit together perfectly. This is important in many projects, if they work as long meant to be connected, then that's the way they'll need to downstream.

A final advantage for pneumatic press brakes is their versatility, via a long list of things they can perform. They are ideal for making many different shapes and angles. That flexibility matters because it means you can scale your work up from small projects well, or use them for any size project you happen to have.

If you have a business that relies on the use of metal plates for its operations, then investing in pneumatic press brake machines could save the company both time and money. By utilizing this machine, you can allow your production line to work stronger so dont be fear it will surely give great results for any of the business.

When using a pneumatic press brake, you will be able to complete metal parts significantly faster and with much more precision than if done by hand. This high-speed accuracy translates into more parts off the machine per unit time. Therefore, you get to complete more project and potentially earn extra. This is why many businesses view them as something really helpful.

So to speak here is an elaboration of the breakdown on How Pneumatic Press Brakes operates. Prior to that, the sheet metal is carefully placed into position on the machine. From there, the athlete using the machine will punch in its target position - say a specific bend angle for sheet metal. Air pressure then pushes on the metal plate in order to bend it at a desired angle.

Pneumatic press brakes are amazing for their accuracy. They can be easily formed into complex shapes and angles. In other words, this precision allows the tool to be as useful in simple projects like a door jamb at 45 degrees all year round or with much higher level of detail for complex assignments.

aware importance after-sales service RD innovation. provide array after-sales solutions such pneumatic press brakeg after-sales press brakes, various products. same time, continue invest research development, support improvements products using latest technologies meet evolving needs customers help customers maintain leading position marketplace.

Quality Builds Trust. We dedicated sheet metal machines ensure every machine is par standards industry. committed providing highest quality products customers. laser cutters press brakes, pipe bending rolling machines.Rapid Market Response: leveraging efficient production supply chain management, quickly meet demands market. time deliver reduced week, if enough stock. enables rapid equipment purchases gain pneumatic press brake advantages.

pneumatic press brake accuracy effectiveness Laser cutting machines handle wide range materials. Rolling machines excellent forming abilities efficient production meet demands many customers. Pipe bending machines utilized mass production due flexibility stability. essentials industrial technology aid manufacturing industry adapt various challenges efficiently, accurately flexibility.

Press Brakes recognized efficiency accuracy suitable various metal sheet processing. Laser Cutting Machines achieve high-speed, high-precision cutting meets pneumatic press brake complicated patterns. Rolling Machines specialized forming metal sheets ensure production quality; Pipe Bending Machines offers flexible pipe bend solutions. product range focused accuracy, efficiency, stability order improve effectiveness quality products.