Creating Custom-Sheet-Metal-Around-the-House Using a Homemade Press Brake

Are you a die-heart person who loves to create the shapes from metal and helplessly looking for tools which is stopping you. Have you thought about building your own DIY press brake from scratch? This simple, yet powerful accessory makes creating accurate bends on your metal sheet a piece of cake and broadens the horizon for creative outputs in all sorts of projects.

Building Your Press Brake in Detail

For the beginning of homemade bending press you will need metal sheet: It consists of base plate, upper beam and bending beam. You'll also need a hydraulic cylinder, a hydraulic pump( which can include the bottle jack) and maybe even some sort of pressure gauge to finish your setup.

Start assembly by firmly bolting the hydraulic cylinder to its base plate. Now add the bending beam to cylinder and upper beam through nuts bolts A press brake is a useful tool which provides accurate and efficient solutions to the supporting needs you require on your hydraulic system.

Press Brake Testing and Calibration

After you have your press brake all put together, its time to see how it works. Use a pressure gauge connected to the hydraulic pump turn on your system. Watch the pressure reading of your gauge as it climbs and feel how gentle euthysia hands you around in a showy round praising this simple homemade miracle that brings together those two parts to push its bending beam down, taking peace from function {.

It might seem terrifying to go on a journey of building your homemade press brake at first, but fret not! The following are some of the essential tips that will help you throughout:

The main thing to consider is that if you will build a specific unit, do plan every inch of it and measure precisely so they fit exactly how your car works.

When selecting press brake material, choose high-quality elements that will support the overall life of your tools, weak metals are not a match for metal-working demands.

If you want to improve your press brake construction and metal shaping, do not hesitate in turning towards experienced fabricators because their advice can guide you along the way.

A Detailed Guide To Renovating Your Workshop With A Homemade Press Brake

With a homemade press brake, you can turn your workshop into more than just woodworking! With every step explained below, get started with upgrading your workshop!

Gather all metallic sheets, hydraulic tools and a wide variety of nuts/bolts/hardware used in your project to aid you when writing the programPrepare workspace with needed supplies

Strategic Planning & Measurement 8.

Consider the size and layout of your press brake, to prepare an accurate schematic that would help you construct it efficiently.

Accurate and Buresa Cuttinginizeme and Setup to dilciniz7075 electronijine final cutatum, you cans better protect your time best in the future if:.

Incorporate cutting equipment to mold the metal sheets into specific form and sizes, then use welding plus bolting procedures in order to set up the parts together.

ONCE THE HYDRAULIC COMPONENTS ARE ON SITE,INSTALL THESE:

Attach the hydraulic cylinder to the base plate in a reliable space and equip it with an integrated hydraulic pump that also connects seamlessly with pressure gauge actions.

Testing Your Press Brake / Tuning it To Perfection:

Then turn the hydraulic pump clockwise and watch the meters against your own hand-made device - if all is working fine then bending of beams would continue smoothly.

$50 DIY Press Brake (PRESS BRAKE PLANS)- Building Metalworking Tools For Beginners:

If you are interested in starting out with metalworking, this can be a long decision process to go through; but ultimately before embarking on your journey it will save time and money which gives the basic understanding of how things work. Now that you have your own personalized tool from scratch, a sense of accomplishment and no cost towards the material or equipment with such as scrap metal.

The Creatives corner: How to handcraft metal anysize orshape with little difficulty

With your DIY press brake, you now have the ability to create complex metal shapes and unique designs for projects. Customize your press brake to suit the intricate needs of DIY metalworking and get ready, set, craft!

Basically, building your own press brake is a satisfying and educational task that will make you better at metalworking. Use the process time wise to set up a clean and detailed metal shape making foundation for your future projects. Begin on your own metallier journey and experience vicariously the restorative power of manual craftsmanship!

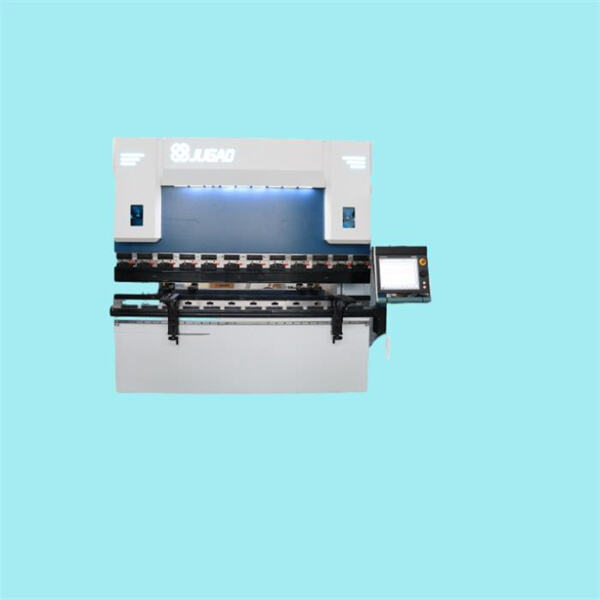

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective Homemade press brake production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.

Press Brakes known reliability precision Homemade press brake various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.

precision efficiency, Homemade press brake cutting machines able deal range materials. Rolling machines thanks amazing forming capabilities high-efficiency production, meet requirements many clients. Pipe bending machines employed mass production thanks flexibility stability. products essence industrial technology, enable manufacturing sector respond different challenges ensuring accuracy, efficiency flexibility.

recognize importance service sales Homemade press brake advancement. laser cutting machines, rolling machines, pipe bending machines, products, provide full range after-sales assistance includes Spanish after-sales services, ensure customers worry-free use. continue invest product development upgrade using latest technologies. helps meet evolving customer requirements keep top position market.