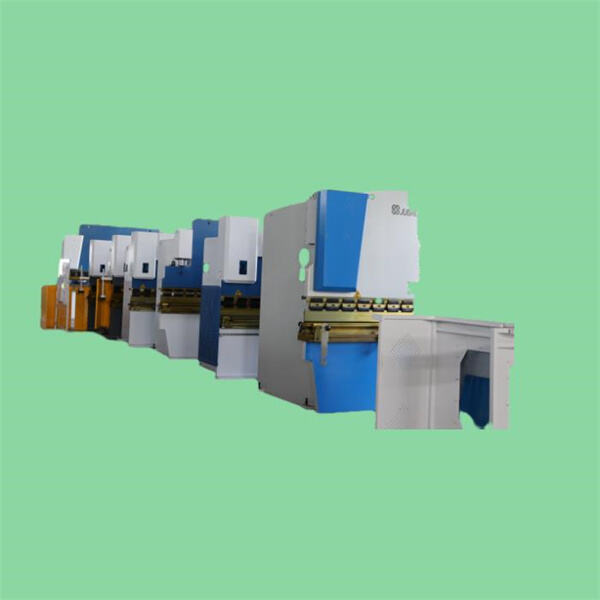

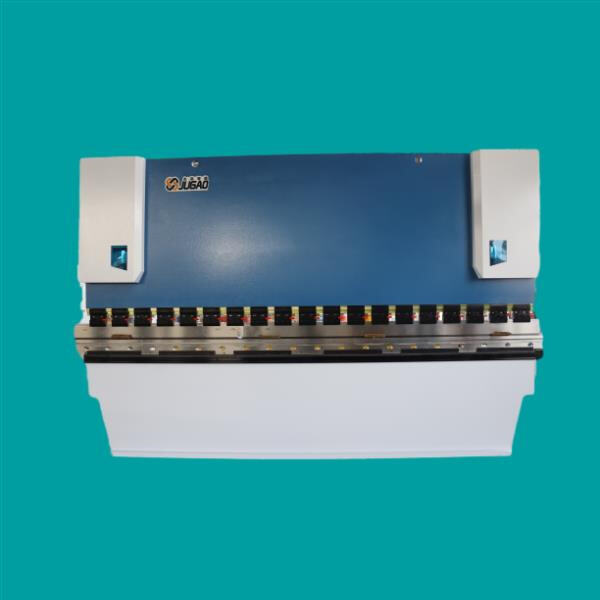

The other companies manufacture large machines called press brakes. "Which are absolutely vital here, as they can bend metal into various profiles. Press brakes are used in factories to forge items out of all sorts of metals ranging from furniture to cars. These businesses still resist the urge to sell all their offers and alternatives that allow you even better machines. The 2021 Ford F-150 Will Put All Other Lethargic Creation Trucks to ShameHere is some worth knowing info on these firms and their amazing trucks.

The press brake machines are planned to bent particular metal in the proper outline. You want to know just where the bends are so that means an angle and a set up. Just like any other industry, press brake manufactures are always on a look for innovative ways to better their machines. They aim for their customers to generate excellent results when they use the tools that are available in them. They are therefore designing the exciting new ways of bending metal more efficiently.

For instance, the thing that make me curious of what if we use robots instead. Robots assist in carrying large, heavy pieces of metal to the correct position on the machine. It is so that the bend made, will be at right location with proper accuracy. In addition, it helps employees stay safe by decreasing the necessity of lifting heavy materials. Companies are also employing computers to run the machines, a concept that you probably can foresee yourself. The use of computers enables the press brake to be programmed so that it can bend a part in specific areas precisely as needed (no more using calipers, protractors and sharpies).

A press brake is critical for producing metal products that are used by factories. This is the reason why everything press brake companies must have strong and reliable machines. These are the machines that have to weather daily use and they need to perform well throughout. If a press brake were to be out of service, it could shut the entire factory down - an expense no one wants on their balance sheet.

And all of them make sure to keep their machines in good shape and ensure they remain reliable by using the best materials available. On top of that, they subject their devices to rigorous tests before shipping them out for sales. In order to do this they need that all of the devices available in their portfolio will be compatible with each other. They also provide assistance to their clients in case of any complications This dedication to quality enables factories run their press brake machines quickly and win all the time, enabling production with no interruptions.

Every factory is unique. They produce different products and with other materials. This is why they require a variety of machines ona press brake machine. This is the reason press brake organizations give one of a kind machines to their customers only. They work with some materials that a specific factory can use, and then bends in exactly the way that each of these factories need them.

The simple designs of the relatively easy solutions governing them are just that. They provide clear instructions and guidance to help factories get going. If this happens, the faster these tools (which would be your press brake machines) are available again at use of manufacturing plants - the better it will be as products can now have production made faster and meet its targets!

Quality Builds Trust. We dedicated sheet metal machines ensure every machine is par standards industry. committed providing highest quality products customers. laser cutters press brakes, pipe bending rolling machines.Rapid Market Response: leveraging efficient production supply chain management, quickly meet demands market. time deliver reduced week, if enough stock. enables rapid equipment purchases gain press brake companies advantages.

press brake companies brakes ideal complex bending operations high pressure accuracy laser cutting machines able deal range different materials efficient high-precision cutting capabilities; Rolling machines, thanks excellent forming capabilities effective production, satisfy needs large variety clients. Needs mass production. Pipe bending machines suitable various pipe processing due flexibility bending dependable performance. essentials industrial technology help manufacturing sector tackle various challenges efficiency, accuracy flexibility.

recognize importance service sales press brake companies advancement. laser cutting machines, rolling machines, pipe bending machines, products, provide full range after-sales assistance includes Spanish after-sales services, ensure customers worry-free use. continue invest product development upgrade using latest technologies. helps meet evolving customer requirements keep top position market.

Press press brake companies renowned efficiency accuracy used many metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting fulfill requirements complex patterns; Rolling Machines specialized forming metal sheets ensure top quality production. Pipe Bending Machines offers flexible pipe bend solutions. product line focuses efficiency, precision, stability help customers improve production efficiency product quality.