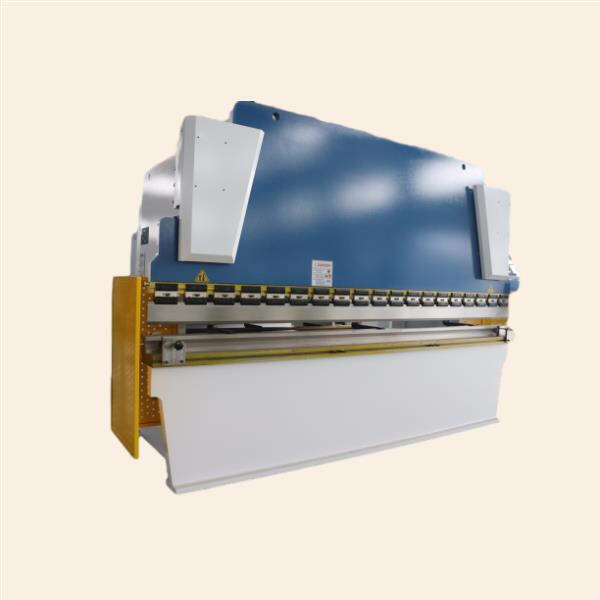

A 90 ton press brake is not something that the average joe would have sitting around, its a metal sheet bending machine beast with very high accuracies when usedcorrectly. Action done on this machine to the metal sheet due to applying a lot of pressure over it results in bending causes and determined its shape operator need.

Press brake is a hydraulic machine for generated bending force to bend the metal sheet. The working of hydraulic on liquid force transfer is known as Hydraulic system, it consumes liquids like Oils to send power and energy Whenever an operator presses the press brake then in order for 2-piece links.a part of a tube into which another fits loosely, containing along its length small openings connecting directly with reserve under pressured,This medium (Stress between liquide) creates excellent features obeying Pascal law due to very high density Unlimited forces action. This means that if I am good at operant., hydraulic will be released oil by cylinder too move pistons downwards). This piston is connected to a ram that pushes on the metal sheet and forms it in this way.

If you work with metals for a hobby, or on the job, then this type of 90 ton press brake can be very advantageous in streamlining and maintaining accuracy when punching bending jobs. Bend sheets to plate box structures is quite cost, so it makes this machine extremely useful with accurate angles & bends thus the results come out really smooth.

Furthermore there are many types of press brakes, so the 90 ton is but one variation in a sea of options. The machine has built-in safety guards for cutting protection and ensures even more security during the metalworking process.

The 90-ton press brake is teeming with characteristics to guarantee top-class performance on every variety of metalworking formalities. What makes it this worth is its features:

Hydraulic system is used to bend the sheet metal by applying required force.

A more unique upper is used, a bed that attaches the metal sheet by bending standing phase.

The back gauge is the mechanism installing in shearing machine tool to measure and manipulate the metal sheet precision position before bending it.

Controller, providing ample control on metal sheet size and slit wirth while in machining bending

When is a 90 Ton Press Brake an Ideal Solution for Industrial Work?

Whoever works in places where more metalworking processes are made on items which should be created using respective type of metals, a 90 ton press brake is one piece that becomes compulsorily required. They not only increase productivity and accuracy but also save time of precious resources. It can handles tasks that would be hard to accomplish by hand (or other means) otherwise.

One other 90 ton press brake advantages excerpt is the ability to match bends across multiple sheets that may be nearly impossible if not very difficult when working with manual bending methods on a regular basis. It can also work with thicker metals in comparison to other machines and thus making this a machine of importance in the industries.

So, I will present some standard tips and tricks that would prove helpful to the new beginners in the area of metalworking or even on a press brake which is consuming 90 tons.

Machine safety guards must be in place before running the machine.

Before you even begin bending, it is important to pull the metal sheet using a back gauge and measure its position individually.

Refine bending even further to hit more precise degrees of bend and shapes - the settings for this can be altered in your control options.

To place the ram correctly, equally apply some force on sheet metal a little so that neither your machine gets damaged nor does the loaded sheet.

Replace Worn Out Quickly: It is a great press brake tip that has to be applied on your machine checking it often and verifying as soon possible any part that might already be having problems, so replace them or have others in start of wear.

In this way, we can understand that the 90 ton press brake is one of those basic metalwork machines which enable you to bend and form sheets with excess rigidity. Knowing the functionality of this machine and learning about its characteristics also add to enhancing their abilities in metalworking which can eventually help it become an essential equipment for any factory that works with repetitive jobs concerning metals. The given basic tips can help beginners to start and as become professional with 90 ton press brake.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle 90 ton press brake materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.

90 ton press brake Builds Trust: Dedicated sheet metal machinery rigorously monitor quality control ensure each machine line industry standards. work hard offer best products clients. From laser cutters press brakes pipe benders rolling, rolling, rolling machines.react quickly market demand leveraging effective supply chain production management. plenty inventory, delivery time reduced week. allows prompt equipment acquisition competitive advantage market.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader 90 ton press brake.

90 ton press brake specialize metal sheet forming high-quality production. Pipe Bending Machines flexible solutions pipe bending. product line focused efficiency, accuracy, stability, allows customers increase production efficiency improve quality products.