Metal bending presses are simply amazing machines we use to form metal, similar to the JUGAO's product like laser cutting machine price. They are incredibly useful tools which can take a type of metal and in an instant shape it with high accuracy to the shapes we need. There are some of the presses which get their award for special reason as they can work in a better and an efficient way through computers. As a result, they can be altered or customised in order to suit specific tasks; all of this makes them very useful for working on particularly difficult metal bending jobs. Read on to find out how they work and why metal bending presses are so vital.

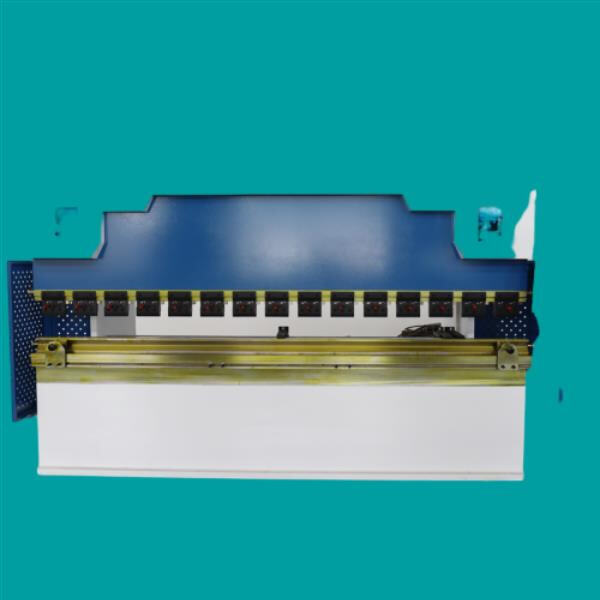

A hydraulic metal bending press uses a piston to perform the operation. A spring is used to push the piston up, and then a force created by pressure of oil or water in cylinder pushes down on this piston with a very strong force. This force is strong enough to bend the metal and give shape of our choice. These presses form the metal plates having diverse size and thickness with this wonderful hydraulic technology. They can also tune the speed and strength of size distortion to get everything running smoothly behind-the-scenes. This makes hydraulic presses ideal for everyone from home garage metalworkers to large factories that require full-sized machines.

A lot of businesses and industries need metal in the perfect shape - Think car making, airplane building, construction, also the laser cutting table supplied by JUGAO. Metal bending presses have a significant role in shaping the metal this accurately. We utilize these tools which need to be user friendly and come in a variety of types so you can fashion any original metal sheet or tube into the perfect piece. Inclusion of the new age technology allows workers to ensure that bending takes place with precision and in uniform manner on all occasion saving time as well as result reflect an excellent work, meeting quality standards.

Computerized metal bending pressesOne of the other great things that have helped us bend metals is computer-controlled Metal Bending Presses, just like the JUGAO's product called cnc pipe bending machine. Because they are more technologically-advanced, these presses contain computers that remember different bend patterns and settings. This system allows workers to program the machine once and not have to reprogram it before every single part which saves hours of time. The computers also regulate the intensity and speed of metal bending, ensuring all elements are accurately matched to requirements. This technology makes the complete bending process more straightforward than before with maintaining superior quality of manufactured modules.

The operator needs to make sure that the weight of the metal sheets or tubes which they are bending, is not heavy enough for his machine otherwise this can ruin down your device.

Hydraulic presses which is an easily customizable option that would be phenomenally helpful in troubleshooting difficult metal bending issues a non-custom machine might not solve. These multi-process presses can be continuously adapted and converted to perform diverse bending tasks, whether for different bend angles, shapes or lengths, also the 1000 ton press brake by JUGAO. In addition, many are configurable to control outputs, pressures and flow rates in their own right. Presses equipped with touch screens and sensors allow operators to bend at greater speed with finer tolerance, adding another layer of efficiency over conventional methods.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease anxiety customers. can respond Metal bending press market demand leveraging efficient production supply chain management. delivery time be cut week, if have enough stock. allows quick equipment acquisitions well as gain competitive advantages.

understand Metal bending press RD as well after-sales assistance. laser cutting machines, rolling machines pipe bending machines products, offer extensive range after-sales support services, including Spanish after-sales support, ensure customers able use product without worry. We continuing invest product development upgrade latest technology. helps us meet evolving customer requirements keep leadership position market.

Press brakes suited bending tasks require high pressure accuracy; Laser cutting machines manage wide range materials efficient high-precision cutting capabilities; Rolling machines, superior forming capabilities Metal bending press production, can requirements huge number customers. Production requirements mass production; Pipe Bending machines ideal various pipe processing due bending flexibility stable performance. products embody essence modern industrial technology help manufacturing industry adapt various challenges, accurately flexibly.

Press Metal bending press renowned efficiency accuracy used many metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting fulfill requirements complex patterns; Rolling Machines specialized forming metal sheets ensure top quality production. Pipe Bending Machines offers flexible pipe bend solutions. product line focuses efficiency, precision, stability help customers improve production efficiency product quality.