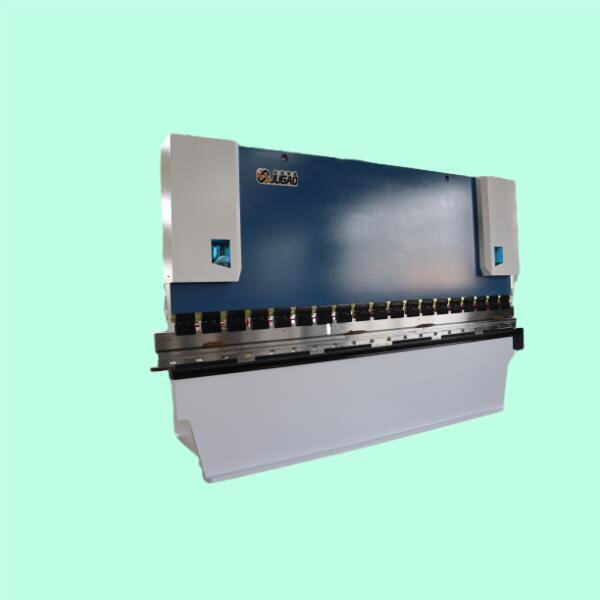

You could be into metalworking, and chances are that you have heard of hydraulic press brakes. The function of these machines is to bend metal sheets in different ways with the help of hydraulic power. Hydraulic press brakes include a robust frame to support all the equipment, hydraulic piston which provides bending force, tool holder that retains the actual bending tools and also bend die which will allows for shaping of metal. Modifying the location of tool holder and bending die you can produce various metal parts that suits for your demands.

Hydraulic press brakes offer even & consistent bending pressure - this is quite a great feature, right? In practice, this means whatever bend you make to sheet metal will be done consistently no matter how thick or wide a piece of sheetmetal is. The importance of this in metalworking is immense because it helps to make sure that all parts mate each other properly. Secondly, Hydraulic press brakes are powerful enough to work with heavy metal pieces - invaluable if you happen to be fabricating large products which require a great deal of power during the bending process.

One more impressive advantage of hydraulic press brakes is they can work fast and very efficient. These machines can do several bends in one piece of metal, saving time and wasting material. With a skilled operator, the machine can be set up to produce shapes such as U-shapes or box shape and even more intricate creations. A hydraulic press brake can perform some very complex bending of metal with the aid of CNC - computer numerical control technology that produces precision results.

Bending metal by hand is much harder and more physically demanding than bending with a hydraulic press brake. With a brake press, the operator can use foot pedals or hand controls to activate the hydraulic piston instead of using your muscles. This enables the manufacturer to form metal without experiencing fatigue and any other internal injuries. Due to this, hydraulic press brakes are great when it comes to create a substantial amount of pieces and also help keep workers safe from any injuries that could occur with manual ways.

Not only do hydraulic press brakes give a constant load, you can also exercise very careful control over the length and angle of your bending. You can achieve exact measurements and angles with accuracy by programming the machine to do so. This makes sure that wrong doings which causes rework and materials to be thrown away. Hydraulic press brakes, also they can typically compensate for any springback in the material to make sure that your final part remains true to form when compared against what you have designed.

The hydraulic press brake allows you to raise your metalworking skills dramatically. Whether you are an average DIY guy doing the small time projects, a larger scale hobbyist pushing bigger and more resourceful tasks or even someone who has been fabricating in metal for years. But this hydraulic press brake would enable you to carry out various other things in your studio as well. If you like to work with metals, then this desktop CNC is probably the solution for all your projects or even assembly of some items by hand as it allows making metallic custom parts and pieces that can help repair cars, machinery if they are no longer manufactured replacement parts on market today; in another way,patent creating his small business from scratch where selling things related machine army but will also include different molds equipment depending manufacturer quality required Continue Doing.

Now that you are aware of the many advantages behind using a hydraulic press brake to get your sheet metal parts bent, let's summarize it all. They are static bender force, meaning you can count on repeatable repeatability from one cycle to the next. Secondly, as hydraulic press brakes work well and can reduce waste it saves an expensive resource of your business - time, which in turn is money. Third, they provide outstanding precision and accuracy which is vital when producing complex metal parts that must be in conformance with extremely tight specifications. Number 4: Last but not least, you can use a hydraulic press brake to challenge your metalworking abilities and do all types of cool new designs. Finally, a hydraulic press brake is versatile and performs well with all types of metal; it can be used in various applications.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Press brake for hydraulic press.

Press brake for hydraulic press Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.

Press brake for hydraulic press efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.

Quality Builds Trust. We dedicated sheet metal machines ensure every machine is par standards industry. committed providing highest quality products customers. laser cutters press brakes, pipe bending rolling machines.Rapid Market Response: leveraging efficient production supply chain management, quickly meet demands market. time deliver reduced week, if enough stock. enables rapid equipment purchases gain Press brake for hydraulic press advantages.