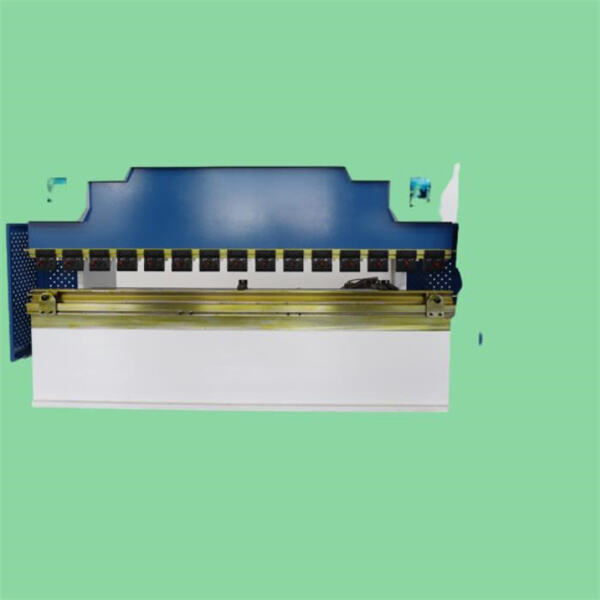

A vice press brake consists of a vise grip at one end and the bending tool on the other. The metal stays in it new place within this clamp due to the tool pressing down on top of itm causing it to bend as a result. That will allow you to set and bend the jig in order for it to be at that identical angle or curve based on your project. This allows you to create a tons of shapes and designs- easily.

With a vise press break, you can make perfect metal bends quickly and easily without wearing yourself out or using your arms as fulcrum. This best of the line machine is remarkable for making small and solid sheet metal bending simply as any various other kind connected with steel or light weight aluminum product. To do a good metalworking project that is not too tiring you need the use of one tool, and in this article we will show how it works.

Vise press brake: Kind of the opposite to our last option, one great thing about this vise press is that it provides long-term precision and reliability. This device is used for precise bends with this apparatus every single time you apply it This means that no longer will you have to worry about fold lines being crooked and asymmetrical, something which can be highly annoying. Hell, you can rock this shit!

The reason this is accurate, and the exact quote of his snarky comment here because I would surpass my recommended daily calorie limit if I tried to summarize it, is that we put smarts into building our tool. It makes it so that the bending tool does enough force on your metal precisely. Which produces the perfect curve that you want to achieve. This means that a simple bend, or even worse curve of an angle will give you better results every time with vise press brake.

Plus a vise press brake is versatile enough to handle various bending jobs. It also cuts aluminum, brass or copper when the steel bending tool.Geometry EditorDesign and draw your own parts CrossOver plateCADing a smaller non-linear area in XZ guiActive) This also means that vise press brake can help in bending a particular metal, irrespective of the type it is.

You may also use this tool to give it different environments such as create plain right bends... even curves and angles. On the other side there is a vise press brake which may be molded it is used to mold many types of metals this flex gives so much if in hand. You can make any part vision inn from of jewelry to a model airplane and even car parts, by using vise press brake aide you in the creation.

Vise press brake - A tool which is intended to last for very long time and need never changed. It is made up of resilient, durable components that are difficult to harm. That also means you can use it day to day across multiple projects and at the end of its life after many years this thing isn't going to fail (thats why I bought one)

Rolling Machines specialize metal sheet forming high-quality production. vise press brake offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.

recognize significance RD vise press brake. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.

vise press brake Builds Trust: Dedicated sheet metal machinery rigorously monitor quality control ensure each machine line industry standards. work hard offer best products clients. From laser cutters press brakes pipe benders rolling, rolling, rolling machines.react quickly market demand leveraging effective supply chain production management. plenty inventory, delivery time reduced week. allows prompt equipment acquisition competitive advantage market.

precision efficiency, vise press brake cutting machines able deal range materials. Rolling machines thanks amazing forming capabilities high-efficiency production, meet requirements many clients. Pipe bending machines employed mass production thanks flexibility stability. products essence industrial technology, enable manufacturing sector respond different challenges ensuring accuracy, efficiency flexibility.