Shear press brake is another very strong and useful tool for metalworking that often uses children in this field Slip roll, along with JUGAO's product handheld laser welders. Metalworking is the process of shaping and creating metal with different types of metals, these tools are used to give a shape onto it. Those tools, as well as the sheer press brake and slip roll make it easy to cut sheet metal pretty precisely. They are versatile so can fit a lot of applications. No matter if you have small jobs that can be done with a speed or big and complicated ones requiring careful work, shear press brake skip roll will do it.

There are few things more important in your metalworking workshop than having quality tools to do the job correctly, also the plate rolling machine innovated by JUGAO. You always get the results of your efforts on using a powerful tools to take care of you work. You will create work more quickly and efficiently with a shear press brake and slip roll. In short, this allows you to complete your tasks faster and in a smarter way. Also, having these tools set up in your shop can help you attract more types of work. Which is terrific as it will help grow your business and you to take on larger projects.

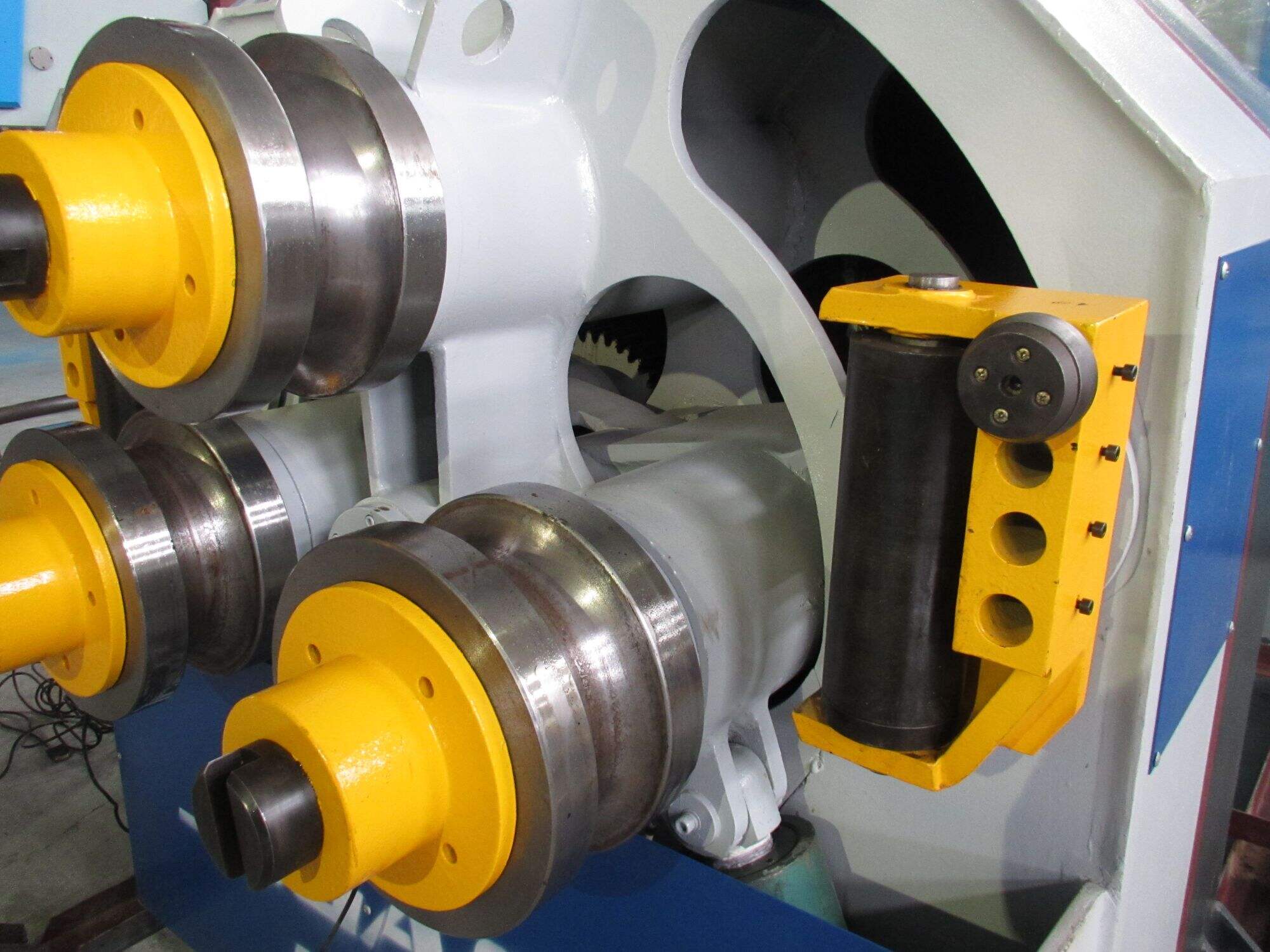

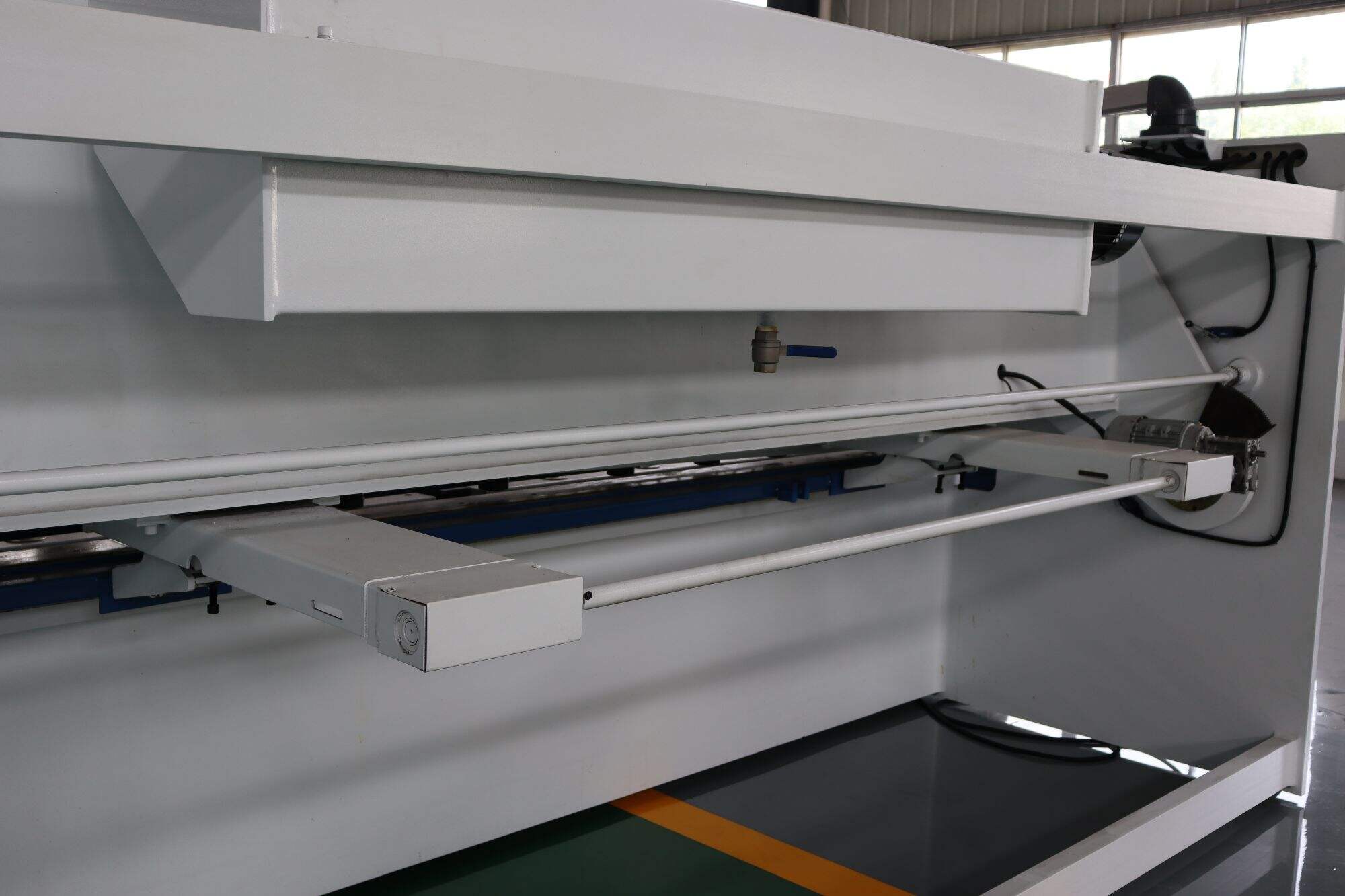

The shear press brake and slip roll are two separate tools with specific uses, but they can be used by themselves or as a whole unit; either for one purpose at first like adding the back gauge to your box and pan sheet metal bending form, same with JUGAO's 90 ton press brake. A shear is similar to a gigantic pair of scissors and cuts long sections into short, more feasible lengths. This comes in handy when you have to work on shorter pieces of metal. A press brake on the other hand, is used for bending metal sheets to form an angle of a sheet. It is useful for manufacturing tight tolerance metal parts that need to fit together with one another. Finally, a slip roll is used to form sheet metal into cylindrical or conical shapes. It can be handy for projects where you have to make cylinders, cones or any kind of repeated sheet-metal part.

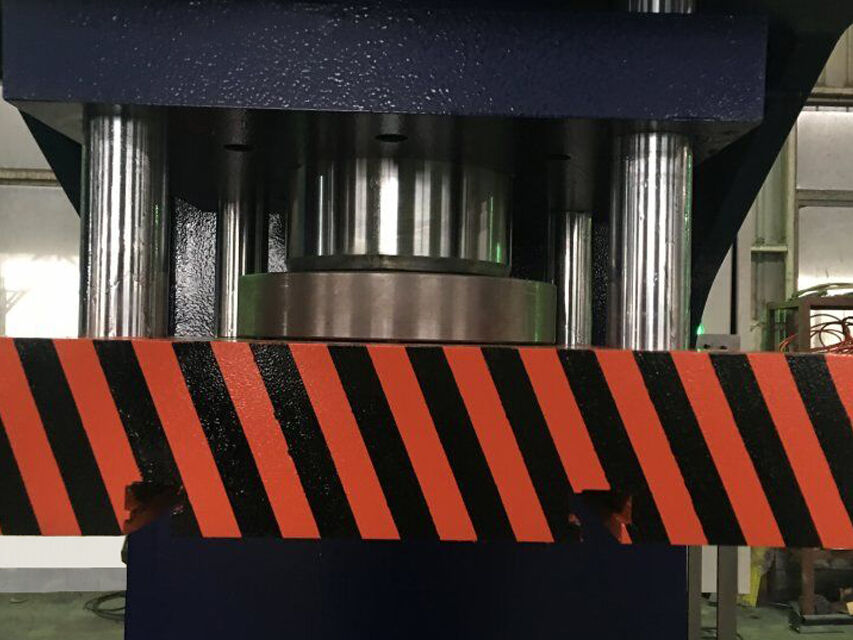

Professorial working with metal is a very important part of the complex process in production engineering wherever funds are at stake, just like when manufacturing a hydraulic press brake. It is here that the shear press brake and slip roll take their turn. Some metalworkers use these tools to do work quicker and more accurately. The shear is good for cutting metal to the exact size corresponding with a project, and press brake can bend the metal at 90-degree angles. In contrast, the slip roll can form both cylindrical and conical shapes- A necessity for many jobs. With these tools in your metalworking kit, you can finish up those tasks right on time and keep them under budget both important things for successful business operations.

To put in a nutshell, the shear press brake and slip roll are one substantial thing for anyone who owns metalwork, similar to the JUGAO's product like 48 inch metal brake for sale. They have all kinds of applications and advantages, so they will be a useful addition to many tool boxes. They are going to allow you to cut and shape metal the way they should be, whether together or separated methods of performance. Therefore, if you think that your skills are at an amateur level and want to do something more progress than before; now is the time where shear press brake slip roll combination can help. They can be the difference maker for how well and fast your projects turn out.

Rolling Machines specialize metal sheet forming high-quality production. Shear press brake and slip roll offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.

Shear press brake and slip roll efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease anxiety customers. can respond Shear press brake and slip roll market demand leveraging efficient production supply chain management. delivery time be cut week, if have enough stock. allows quick equipment acquisitions well as gain competitive advantages.

Shear press brake and slip roll aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.