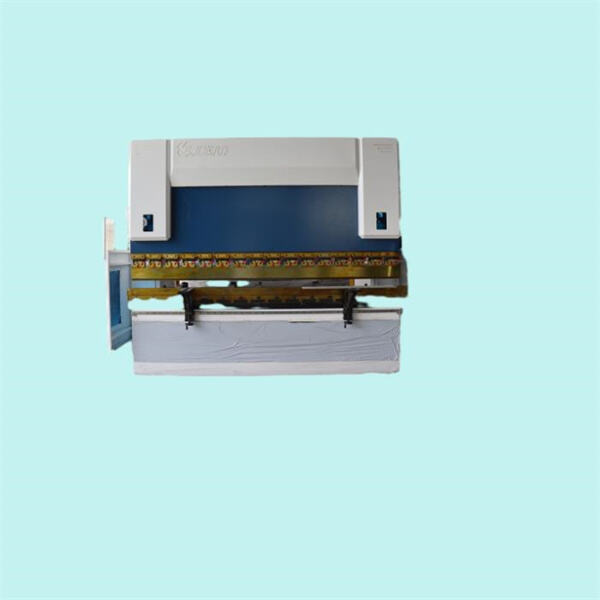

Pressbrakes are the machines which convert metal into different formations. They have a lot of srength and can preform many feats. Read more → An Introduction to Pressbrakes Read how pressbrakes can work for you and why the industry standard is here!

Pressbrakes are machines that forces beyond large. They can put a lot of pressure on metal so that it is bent into the shape to make what we need. The reason for this is the correct shape of your projects vary. A good instance would be bending the metal as a rectangle, to produce a rectangular box. This process is significantly faster and easier when using pressbrakes. Bending metal by hand would be wildly time-consuming and exhausting if we didn't have pressbrakes.

Big factories have lots of machinery that work together to produce different things. Pressbrakes are one of the highest demanded machines in these factories because they allow to bend metals into many shapes required by a large number of products. There are so many things, such as automobiles that needs certain parts of metal to cut accordingly. These parts would be complex and time consuming to manufacture without the assistance that pressbrakes provide. The newest pressbrakes are supposed to be much faster and more accurate compared with old style types, which allow factories then therefor make even a little product in less time. Especially useful for businesses!

Pressbrakes are extremely versatile machines. This career versatility is what helps them get into lots of different jobs! They vary in size as well, and some can work with metal of various thicknesses. This is significant because not every type of project can use the same size and thickness metal. Rectangles, squares, and even circles can be fabricated with pressbrakes. This makes them extremely handy in a lot of situations as they can adjust to different needs.

Pressbrakes are one way factories save time and money. Molds allow for the rapid and accurate production of a variety of shapes which make them an essential feature in making factories produce more with speed. This cuts down on labor costs as workers do not need to spend so much time producing each part. Furthermore, pressbrakes create an accurate cut causing less material waste. Efficiency is key in factories, as any waste can accumulate to a lot of money lost over time.

Pressbrakes are versatile machines which can bend metal into various shapes, dimensions etc very easily and faster in comparison to other format. This fact just makes them that much more important in the manufacturing process. The ease with which we make the items that each of us uses and owes its existence to pressbrakes would be much harder. They can also work with different materials such as steel, copper and aluminum which makes them being useful in diverse projects.

recognize importance after-sales service RD advancement. press brakes, laser cutting machines, rolling machines, pipe bending machines, other products, provide entire range support after sales includes Spanish after-sales service, make sure customers enjoy Pressbrakes experience. same time, continue make investments research development encourage latest technology product development meet ever-changing needs customers, assist customers maintain position market.

Pressbrakes accuracy effectiveness Laser cutting machines handle wide range materials. Rolling machines excellent forming abilities efficient production meet demands many customers. Pipe bending machines utilized mass production due flexibility stability. essentials industrial technology aid manufacturing industry adapt various challenges efficiently, accurately flexibility.

Quality Builds Trust: Pressbrakes sheet metal machines meticulously supervise quality control ensure machine is line industry standards. strive provide highest quality products customers. laser cutters press brakes, pipe bending well as rolling machines.Rapid Market Response: leveraging efficient production supply chain management, we able quickly meet market demands. ample inventory, delivery time reduced week, enabling prompt equipment acquisition market advantage.

Press Brakes renowned accuracy efficiency ideal variety processes metal sheets; Laser Cutting Machines achieve high-speed Pressbrakes cutting order meet complex pattern requirements; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability order improve production effectiveness quality products.