What is a CNC press brake machine For those who are not familiar with the device, it may appear bulky and complicated at first sight; nonetheless, It is a handy tool in the world of metal fabrication. We will explain how this machine works and explore all the improvements it brings to increase efficiency and productivity during manufacturing processes.

A CNC press brake machine is a type of special purpose machinery that bends metal sheets in different shapes through bending process. The title "CNC", represents forDefinition of Computer Numerical Control which implies the machine is controlled by a set of specific instructions that are input into directional software. This makes the robot capable of preforming movements with exact precision and repetition, which in turn allows projects to be completed more quickly and efficiently.

Recent developments have taken place in the landscape of CNC press brake machines which has enhanced their high levels of precision and efficiency. In the current era, most machines use laser technology to measure and locate a metal sheet during production in real-time which allows for immediate corrections. In case of deviations in the thickness or form of the material, it readjusts efficiently and maintains high-quality parts downstream.

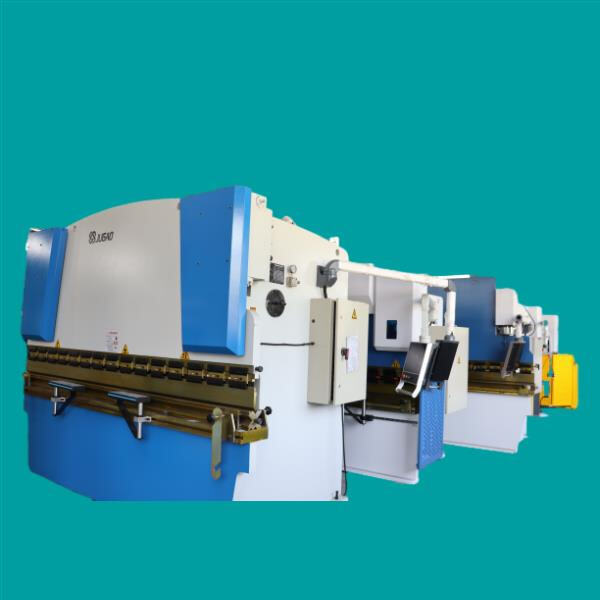

Our CNC Press Brake Machine that Moulds Intricate Bend Angles and Custom Made Outfits

The above feature symbolizes the distinctive attribute of a CNC press brake machine which is its ability to bend fine angles and configurations with immaculate precision. This machine can easily shape or angle according to the need of a design evolution and does not require hand intervention. By doing this, it has not only saved time and will power; but should ensure the same level of excellence in every piece fabricated.

The implementation of a CNC press brake machine can significantly change the course of manufacturing sectors and boost their production procedures. For example, by letting the machine produce very exact angles and special designs instead of doing this manually it can build up a high-quality product in less time which means that manufacturers are able to do more projects on scale faster then before with these products produced.

A CNC press brake machine is versatile and enables you to create a wide variety of products without any complication, while significantly driving up your productivity. The program and settings are flexible, which can be very easily adjusted because of its user-friendly interface guaranteeing the product is flawless according to customer individual requirements. In its truest sense, this machine marks a hallmark of innovation in manufacturing that enables users to get more done so by providing the desired outcomes each day.

Conclusion: A CNC press brake machine may become intimidating at first, however do no longer underestimate its fee as a treasured tool to manufacturers. This exemplifies the pinnacle of how far technology has come in manufacturing, creating perfect angles and customizing 24/7 with top-of-the-line tech to help maximize an already efficient system. This book shows how that versatility enables production of a diversity and complexity of items, much more accurately than was possible before an invention revolutionized the way things are made in factories.

Press brakes suited bending tasks require high pressure accuracy; Laser cutting machines manage wide range materials efficient high-precision cutting capabilities; Rolling machines, superior forming capabilities Cnc press brake machine production, can requirements huge number customers. Production requirements mass production; Pipe Bending machines ideal various pipe processing due bending flexibility stable performance. products embody essence modern industrial technology help manufacturing industry adapt various challenges, accurately flexibly.

Quality Cnc press brake machine Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

Rolling Machines Cnc press brake machine metal sheet forming high-quality production. Pipe Bending Machines offer flexible solutions pipe bent. product line focused precision, efficiency, stability, allows customers increase production efficiency improve product quality.

understand Cnc press brake machine RD as well after-sales assistance. laser cutting machines, rolling machines pipe bending machines products, offer extensive range after-sales support services, including Spanish after-sales support, ensure customers able use product without worry. We continuing invest product development upgrade latest technology. helps us meet evolving customer requirements keep leadership position market.