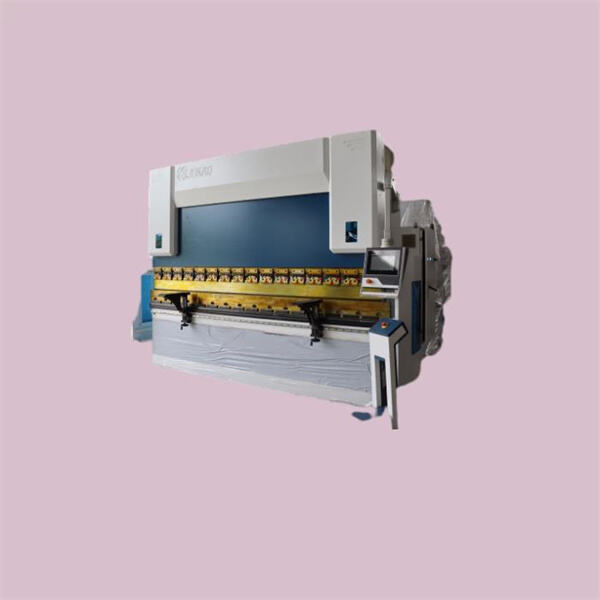

Page NavigationMost Important Tool Used In Factories Is Press Brake Machines These wonderful tools help workers to bend and give a systematized shape for the metal. These machines will also help manufacturers ensure the steel is properly bent. Which helps to produce products less valuable, and because their materials are saved (save the planet), this both goes for a production of high-quality.

Easier manufacturing means making it simpler for people to get what they need in order to perform their job faster and/or better. This is where press brake machines come in. They help in bending metal simply to choose any shape or size. This reduces the amount of time that workers need to spend bending metal, which lets them focus on other important projects.

Last but not least, a few of these press brake machines also can work automatically. This implies that they can do a wide range of task without much help from workers Factories will save greatly from automation such as this. If machines have the ability to work fast without help, then we can quickly produce more products in a set span of time. This can prove advantageous when it comes to getting a sizable output so that business becomes more profitable.

For those are not that familiar with these machines, press brake is a machine tool used to bend flat metal sheets into different kinds of shapes. Household appliances and parts, automotive components, construction materials are only a few familiar objects that these machines manufacture.

Are press brake machines difficult to use? To initiate, you simply put a sheet of metal onto the flat table simple machine. From there you lock the clamps to secure that your sheet wont move at all during operation. Once the sheet is in place, you will have to select a programme for how rapidly the machine moves. You also determine the size of the bend because it depends on how much of your shape is to be made. This enables you to reach the exact angle and curve required for end resultbegins.

Hydraulic press brake machines are operated using specific oil which works upon the machine and makes them move. They are extremely powerful and great for heavy works. This makes them an ideal tool for bending thicker pieces of metal in industries that work with larger materials.

But with new technology the press brake machines have greatly enhanced to such an extent that they work faster, are more capable and are accurate. The modern machinery may be equipped with advanced computer systems and sensors that assist their functioning. This tech does so much to support that even first-timers can use them like a pro.

press brake machine efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.

press brake machine Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.

understand press brake machine RD as well after-sales assistance. laser cutting machines, rolling machines pipe bending machines products, offer extensive range after-sales support services, including Spanish after-sales support, ensure customers able use product without worry. We continuing invest product development upgrade latest technology. helps us meet evolving customer requirements keep leadership position market.

Quality Builds press brake machine: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.