Another tech we have in a lot of factories is Press and Shear. It is very advantageous as it moulds the materials into different forms for making various products. This technology is widely used to make car, airplane and building parts. When it comes to knowing the essence of this, we could really understand how crucial its application is in our daily living.

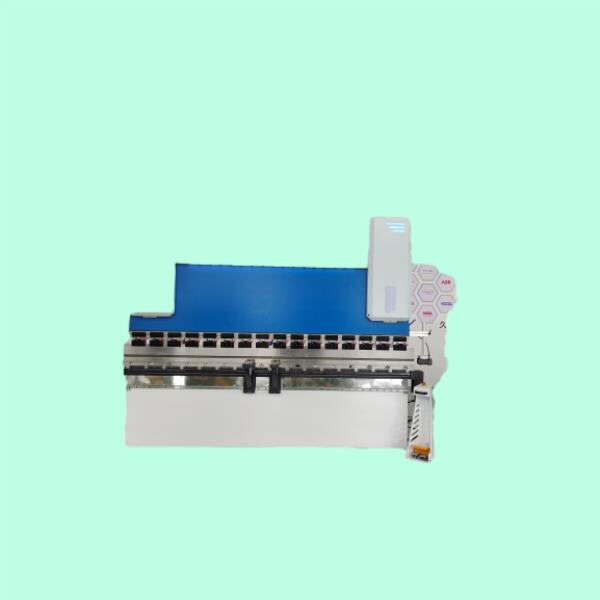

The Press and Shear Technology The unique feature of the P&S technology consists in examination two separate parts working coherently with each other one for the press, another -for shear. Definition : A Press is a mechanical tool for creating compression and shear forces to metals. The machine works in a similar way to your day 1 creation of pressing down on fresh clay with the flat palm of one hand. The shear, however, is created to reduce the thickness of those materials into different ways and sizes. It is just like forming paper into different shapes by cutting it with scissor. The combined use of these two elements allows the factories to produce the products used in daily life.

The use of Press and Shear technology is a major asset to factories. It has a great impact that on increasing work speed in factories. They are fast and can perform jobs with high accuracy - so workers in turn also become really productive to produce more products within a certain time frame. This pace is critical for scaling to fulfill a demand and serving the customer.

Using Press and Shear technology also creates less waste. Since the machines are very precise in cutting and shaping materials, therefore there is almost negligible amount of wastage left behind post completion. Not only is this good for the environment, but it also means that less money needs to go into waste and more can be used elsewhere in factories.

Machines behind Press and Shear technology generally require to be maintained well for efficient use of the same. This involves washing them by adding oil to move smoothly and verifying that all the parts are working voter. Keeping up these machines, similar to an auto holds longer and works better when consideration and upkeep are performed routinely during the time.

Workers also needed training to operate the machines in a safe and efficient manner. For all concerned, however should they be transferred from one location to another business is as easy and convenient possible combine with proper training where everyone will know how to run the machines without getting hurt. It helps in the safety of workers as well as overall running efficiency and even pedestrian is able to factory operate better.

After all, the appliances themselves should also be designed to clean and maintain your machines. It also means that there should be serviceable parts accessible so workers are able to do some form of maintenance without too much difficulty. This is crucial to accomplishing the highest levels of productivity with least amount downtime.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle Press and shear materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.

Rolling Machines specialize metal sheet forming production quality. Pipe Bending Machines offer flexible solutions pipe Press and shear. product range focused efficiency, precision, stability help customers improve production efficiency quality products.

understand importance RD support after-sales. provide full assortment after-sales service include Spanish-speaking after-sales Press and shear well as other products. continuing invest development products update latest technology. helps us meet evolving customer requirements keep position leader market.

Quality Builds Press and shear: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.