MKT press brake axisWhen speak about a certain press brake axis that means the way by which A Mechanical force is introduced to metal sheet so It can be bent or shaped. A press brake machine normally consists of two dominant axes: the X-axis and the Y-axis. The X-axis moves Left to Right and the Y-Axis Up and Down. They make it possible for the press brake to bend metal sheets into forms like we need in a host of projects. Together, these axes ensure 3D rotation and bending accuracy are high-level enough to produce excellent metal shapes.

The reliability of the axes positioning is extremely important too, nothing works smoothly if a press brake cannot put its selves in ideal position. Otherwise, we would have the metal sheet bend in a different axis than that needed. This can make a metal sheet unserviceable and even dangerous if sharp edges or incorrect forms are created. For this reason, it is extremely important to ensure your press brake in always correctly setup and adjusted. Routine inspections and maintenance work save the machine long-term performance, helps to prevent any potential problems from causing a breakdown.

When choosing a press brake axis, it is absolutely essential that you take into consideration just what exactly shall be put to get the job done. Some jobs might need axes to be a moving type in different ways. For instance, some jobs have more accurate movements and others require a very wide range. Picking the right press brake axis will enable you to put intractable bends easily and accurately on your metal sheets. The choice is personified and simply drives the time of waste has been established to commit errors in future.

There are times when everything is configured correctly in the braking system and yet problems might arise while using the press brake axes. Here are some of the common problems you may encounter and how to resolve them.

The axis stops swinging: This is most likely caused by an accumulation of dirt or random things, and you will not get to them. A thorough cleaning often solves this issue and makes the key more fluid.

The axis is not aligning: The alignment of the axis might be off because parts responsible for monitoring and correcting may have worn out. Renewing all of these parts can enable a closer-to-shop applied result.

Faulty axis motor: Not functioning could either mean the motor itself is faulty or there is an issue with electricity running to it In that case, you can ask the help of a professional service to identify and solve the problem correctly.

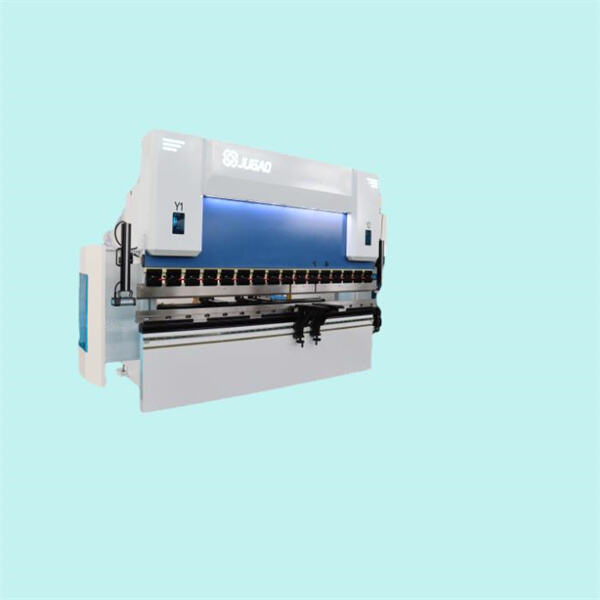

Press brakes suitable complicated bending processes due pressure precision laser cutting machines able manage wide range materials because precise precise cutting capabilities. Rolling machines, with excellent Press brake axis capabilities efficient production, satisfy requirements huge variety customers. Pipe bending machines utilized mass production adaptability stability. machines embody essence latest industrial technology manufacturing industry respond various challenges efficiently precision, speed flexibility.

Quality Builds Trust: Press brake axis sheet metal machines meticulously supervise quality control ensure machine is line industry standards. strive provide highest quality products customers. laser cutters press brakes, pipe bending well as rolling machines.Rapid Market Response: leveraging efficient production supply chain management, we able quickly meet market demands. ample inventory, delivery time reduced week, enabling prompt equipment acquisition market advantage.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Press brake axis.

Press brake axis Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.