Ever wondered how large machines are able to fold metal sheets exactly at the right angles? This is accomplished with a machine that we call the press brake. The machines are primarily made by one famous company called Baykal. The press brake from Baykal is different because it can bend the metal sheets with precise thickness. But what does accuracy mean? This ensures that the device is able to form the metal into a precise angle required for any instrument. In manufacturing, and other types of industries the ability to maintain precision is critical because even a small mis-measurement can cause great headaches.

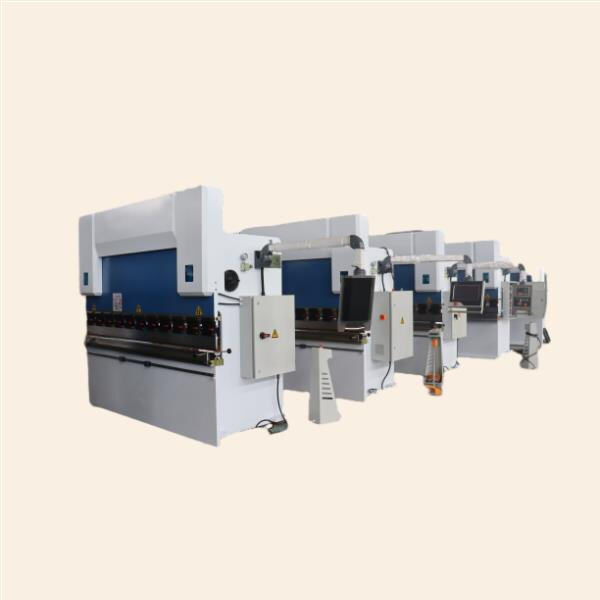

Now, try to imagine bending sheet metal using only human power. And this would be next to impossible, right? - since trying to get every bend perfect too... This is why companies used machines named press brakes, especially Baykal press brake. Say goodbye to inaccurate bending forces, with Baykal press brake all bends will end alike as they start. This leads to packages that are not only accurate but look professional and of high quality for the consumer. By consistently making the same product business creates a level of trust with consumers, who then know that they are guaranteed to receive a quality item.

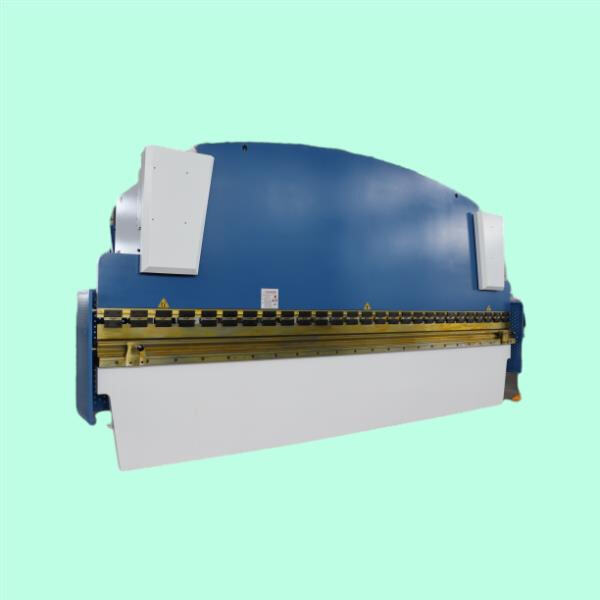

Well, how does the press brake of Baykal work? But all of that aside - my favorite part is the fact it uses hydraulic energy. This means that it relies on liquidity for the power.TRAILING NEXTterrorism Imagine of there is a waterfall, then the water gushes down and strikes everything with great upsurances. All like how Baykal's press brake uses liquid to push against the metal sheet to make that bend. This strong method of bending keep the metal positive about bend and exact.

The most exciting trait of the press brake from Baykal is its versatility. It is compatible with various metal sheets, such as steel and aluminum. It is versatile, and can even take on thicker or thinner sheets. That means that Baykal's press brake is more than able to handle a company requiring the bending of surgical sheet metal as well as light and heavy gauged, inch-thick steel. It allows manufacturing plants to win a variety of projects requiring different metals without the need for multiple machines.

Now, what about efficiency? Companies want to produce products as quickly and cheaply as they can. Thisi s where a press brake like the one here from Baykal comes in to save your sanity. Its sophistication is the result of high tech which makes it very effective. For instance, it is a computer system that automatically programs the machine to bend or fold up sheet metal in specific contours. This, in turn would mean that this machine is autonomous enough to operate and adjust itself without a human manipulating it on each occasion. Use of these established docs inherently saves time and smoothens the process.

In addition, the press brake by Baykal has a quick ram return. That simply means that your machine can jerk the metal back to original initiating point even faster. This allows you to make another bend immediately. For that reason, the entire manufacturing process is made significantly quicker than if everything was manually done. These machines save a significant amount of time, allowing for more products to be produced in less time and hence improving productivity at the business end.

At last, the compressive strength. What is that? It is the amount of force a material can resist with before it will break or bend. As one of the strongest press brake, Baykal is able to perform some metal related heavy tasks due its high compressive strength. Within such sectors, the desire to use materials with high tensile strength is a priority since the capacity for making solid products (aeronautics parts or constructible fabrics) only belongs here. Safety and Durability: Quality Products (Strength Goes a Long Way...)

aware importance after-sales service RD innovation. provide array after-sales solutions such Press brake baykalg after-sales press brakes, various products. same time, continue invest research development, support improvements products using latest technologies meet evolving needs customers help customers maintain leading position marketplace.

Press brake baykal Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective Press brake baykal production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle Press brake baykal materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.