A metal shear and brake is a powerful device that makes cutting metal sheets a cinch. It is commonly used in workshops and factories for metalworking and shaping applications. The press functions much like a lever that presses down firmly on the metal sheet and snaps it along a straight line. This requires careful workmanship and strength of arms to insure that the cuts are clean and straight.

As with any type of metal shear press safety is of the utmost importance. Whenever using chemicals or solutions, make sure to wear protective equipment such as gloves and safety goggles to stay safe. Read the operator's manual befoer using the press to understand the controls and settings.

To operate the metal shear press skillfully, plase ensure that the metal sheet lines up and fixed on both sides of the machine before starting the machine. Set the blade according to the thickness of the sheet of metal you are working with so that you do not get bent metal. It’s also important to press down on it evenly when cutting so you don’t get rough edges.

Also, a metal shear press aids in the quality of your work as they can create perfect cuts every time. It can delight customers and bring them back. And if you own a metal shear press, it can even save you money in the long run as you’ll be able to avoid paying for cutting services.

There are several types and models of metal shear presses depending on the units and options provided by the manufacturer. Some are little more than presses for cutting through paper; some are rugged enough for the mighty task of heavy industrial stamping operations.

Your metal shear press needs to be taken care of so it can continue to serve you for many years. Clean it often and oil the moving parts that it doesn’t get rusty and runs smoothly. Inspect the blades for wear and replace if necessary to continue making good cuts.

Be up on problems with your metal shear press, such as cuts that aren’t perfectly even or other problems, and address them immediately. If you need do, consult the user manual for assistance or a technician for help. Every bit of damage that occurs can overwhelm the press, and that’s the key reason it is crucial to fix issues early.

Quality Builds Trust: metal shear press sheet metal machines meticulously supervise quality control ensure machine is line industry standards. strive provide highest quality products customers. laser cutters press brakes, pipe bending well as rolling machines.Rapid Market Response: leveraging efficient production supply chain management, we able quickly meet market demands. ample inventory, delivery time reduced week, enabling prompt equipment acquisition market advantage.

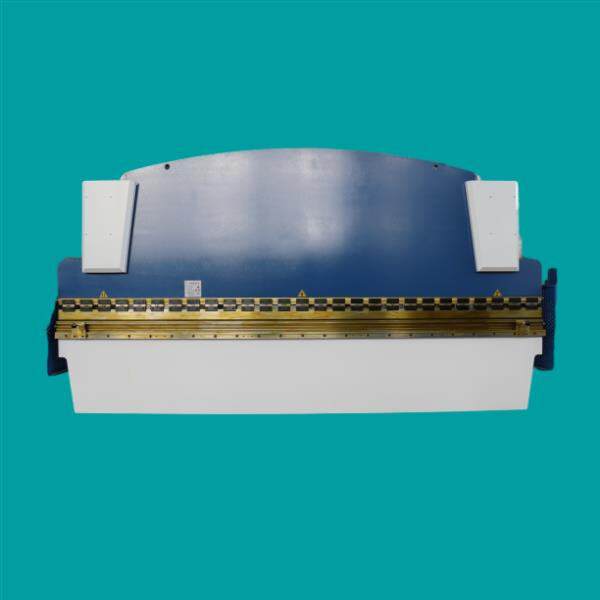

Press Brakes recognized efficiency accuracy suitable various metal sheet processing. Laser Cutting Machines achieve high-speed, high-precision cutting meets metal shear press complicated patterns. Rolling Machines specialized forming metal sheets ensure production quality; Pipe Bending Machines offers flexible pipe bend solutions. product range focused accuracy, efficiency, stability order improve effectiveness quality products.

understand metal shear press RD as well after-sales assistance. laser cutting machines, rolling machines pipe bending machines products, offer extensive range after-sales support services, including Spanish after-sales support, ensure customers able use product without worry. We continuing invest product development upgrade latest technology. helps us meet evolving customer requirements keep leadership position market.

metal shear press accuracy effectiveness Laser cutting machines handle wide range materials. Rolling machines excellent forming abilities efficient production meet demands many customers. Pipe bending machines utilized mass production due flexibility stability. essentials industrial technology aid manufacturing industry adapt various challenges efficiently, accurately flexibility.