What Are Some Good Tips For Running A Press Brake Project? One: You should also think about what you want your project to look like (and do) when it is done. If you want to organize your thoughts, letting some ideas flow out at first instead of focusing on making things perfect just like this: Sketc h it or make a small model with clay or another material I got mine from my kids room and kept interacting - which makes much easier upbringings for those who use pens. This way you will learn your design and make certain that You then have it in place before you begin working with the metal to achieve a similar idea of what we want from our wire shaping. Second of all, measuring everything is so important. This will also help you understand what would be the right size & shape for all your pieces. Measuring properly is important because it can prevent errors and ensure that everything fits well together. Last but not least, during press brake work remember to be patient. Metal work is tricky business; try to rush it, and you'll probably regret the errors made along with way. Well, take a deep breath and enjoy the ride of making something from scratch!

If you hope to produce the best results on press brake projects, it is important that you learn how to work quickly and efficiently. A great way is by using unique tools or some techniques which will improve your work. Or like using a bending tool to bend several times at once. This will lead to not only time saved but also less errors done as you can cater everything properly. You can even implement machines or automation intended to position your workpiece accurately and rapidly. The use of such tools and methodologies will enable you to get more done at a faster clip, allowing you to create awesomer projects with fewer bugs. This way you get to have even more fun - whatever that looks like for you as part of the process.

The number of projects that you can create with a press brake is absolutely staggering and very creative! A strong and unique metal bench, or a fancy artistic piece like this hanging steel screen that you can hang on the wall of your house. You could even try crafting a metal sculpture to embody your wonderful ideas if you getartsy. Another interesting use is to create metal brackets that hold shelves or other items you have around your house in position. You may also consider fabricating useful objects such as a tin box for your tools or yard art. Press brake projects are many and varied so let your imagination run wild in creating whatever is you choose!

After you have finished making press brake projects, one of the best parts about them is that they can be shown off. While the service has ended, you might still end up with a beautiful project that can be displayed in your home - something for your whole family to appreciate. If you make it and love your work, dare to try your hand at a metalworking contest or how does what did I do. It feels great to share your victories If you like what you made, post it on social media or write a blog (something complete different) about how amazing your creation was. This can be motivation for other people to make a press brake projects. Do not underestimate how many will appreciate your creativity and hard work!

If you are interested in press brake projects but a little unsure of where to begin, the following information can provide some clarity. The first thing that you have to do is choose a metal piece which you want it to be bent. It could fall under 2 categories: a flat piece of metal, or one you want to shape. You will then use a press brake to bend the shape of your choice into the metal. The press brake uses a die and punch to make the metal bend in he right shape. There are a few different styles of dies and punches that can be substituted out to make particular bends in your design, so you have some options when choosing the ones best for your project. And last but not least, after you have formed the metal then finished your piece by sanding or polishing it. This step will give it a good appearance, full, smooth and ready to use.

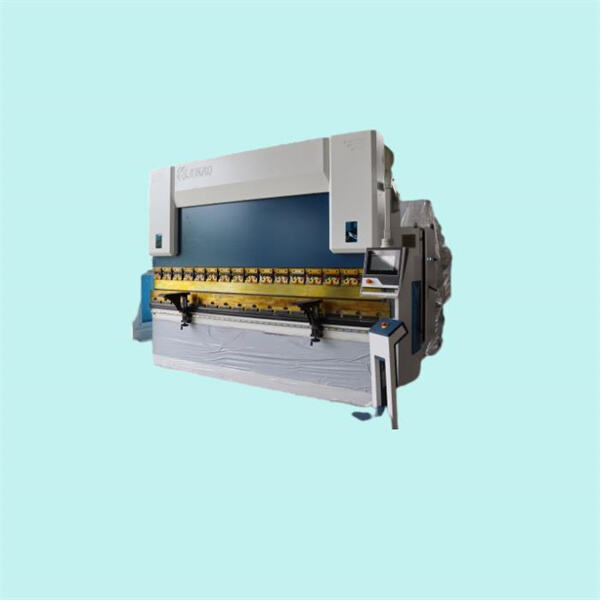

Press brake projects Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.

Quality Builds Trust. We committed sheet metal machinery assure every machine sell up industry standards. laser cutters rolling pipe bending machines, strive top-notch products ease worries.able Press brake projects quickly market needs utilizing efficient production supply-chain management. ample inventory, delivery times cut just week, allows rapid acquisition equipment gaining market advantage.

recognize importance service sales Press brake projects advancement. laser cutting machines, rolling machines, pipe bending machines, products, provide full range after-sales assistance includes Spanish after-sales services, ensure customers worry-free use. continue invest product development upgrade using latest technologies. helps meet evolving customer requirements keep top position market.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle Press brake projects materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.