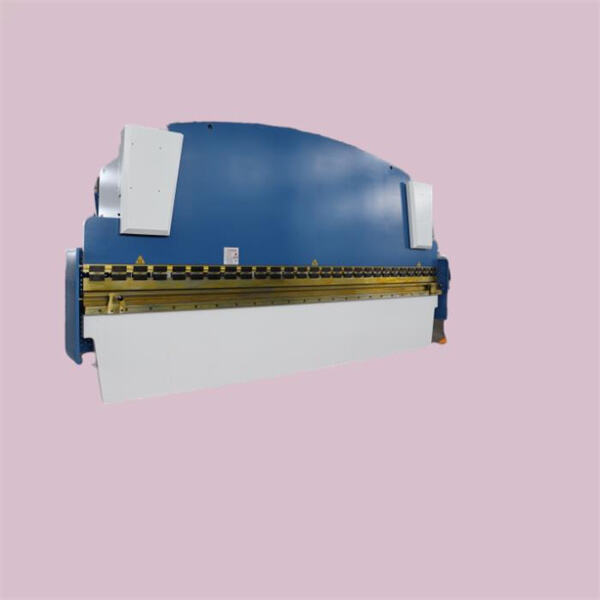

An electric press brake is a unique machine, formed by electricity to shape metals. An electric press brake works without oil, so there is less need for maintenance and it respects the environment more than traditional machines. This revolutionary breakthrough in metalworking technology has many advantages which can dramatically improve businesses.

Transforming the metalworking process by acquiring an electric press brake This tool not only saves you time, but also increases productivity due to an electric motor instead of hydraulics. Electric press brakes are also a low-maintenance, oil-free solution that runs more smoothly over time than normal press brakes which need constant upkeep and oils changes to even keep them working.

The electric press brake is precision, lightening fast. These machines are integrated with software that calculates the precise amount of pressure needed to bend metal and as a result, they leave less room for error which would save resources in the long run. In addition, electricallypowered press brakes are faster than their traditional counterparts allowing companies to accomplish more work and perform it in a shorter amount of time.

Electric press brakes for sometime now have been on the rise from more developments to increasing their green credentials. Thus they are faster, efficient and have great precision making them the machine of choice for many businesses in metalworking. In conclusion, it is also important to analyze the characteristics of your metal, size and capacity options on its machine type as well as available technology features.

In the end, electric press brakes offer a lot of advantages that traditional lever operated machines do not. As such, with their velocity, accuracy and pace; therefore the businesses additionally make a contribution to cleaning up our world. This results in a much faster overall bending experience - one that can save time and money, driving the bottom line for businesses investing in an electric press brake.

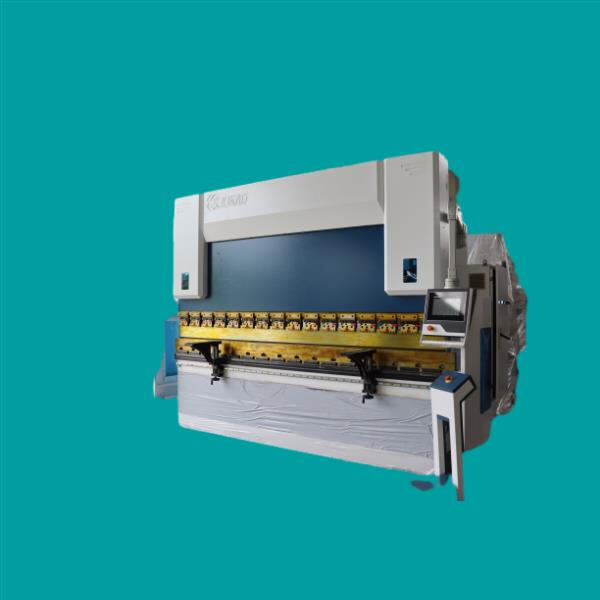

Press brakes suitable complicated bending processes due pressure precision laser cutting machines able manage wide range materials because precise precise cutting capabilities. Rolling machines, with excellent Electric press brake capabilities efficient production, satisfy requirements huge variety customers. Pipe bending machines utilized mass production adaptability stability. machines embody essence latest industrial technology manufacturing industry respond various challenges efficiently precision, speed flexibility.

Press Brakes renowned accuracy efficiency ideal variety processes metal sheets; Laser Cutting Machines achieve high-speed Electric press brake cutting order meet complex pattern requirements; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability order improve production effectiveness quality products.

Quality Builds Trust. We committed sheet metal machinery assure every machine sell up industry standards. laser cutters rolling pipe bending machines, strive top-notch products ease worries.able Electric press brake quickly market needs utilizing efficient production supply-chain management. ample inventory, delivery times cut just week, allows rapid acquisition equipment gaining market advantage.

understand importance RD support after-sales. provide full assortment after-sales service include Spanish-speaking after-sales Electric press brake well as other products. continuing invest development products update latest technology. helps us meet evolving customer requirements keep position leader market.