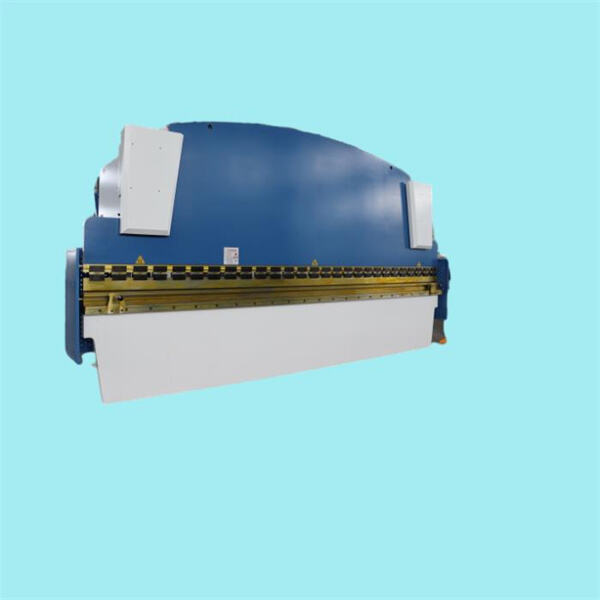

Come and see this curious electric press brake machine World of ours! This invention is widely used in the metalworking industry to effortlessly bend sheet metals into several different shapes.

The process of bending metal in this shape was originally only a quality that could be done by machine, powered either hydraulically or mechanically. But one of their feature which has changed how sheet metal bending is done, the electric press brake machine. This new innovation has opened up an era of unheard-of accuracy and efficiency.

An electrical press brake is a machine that has numerous benefits to it. Firstly it is environmentally naturally because that never release any unwanted elements to all of the environment. In addition to their precision, they make the process more productive as well due to rapid cycle times. Plus they are sleekly-designed ideally for safety, so you can have a piece of mind that you purchase something durable versus just some old trash bin.

The best electric press brake machine can be used to bend sheet metal in various shapes. These machines will do anything from your less than-stellar bend to virtually any complicated folding one can imagine. One of its biggest pluses are the ability to be adjusted cause they can bend metal with different weights very easy Being multi-functional and able for any type if metalling.

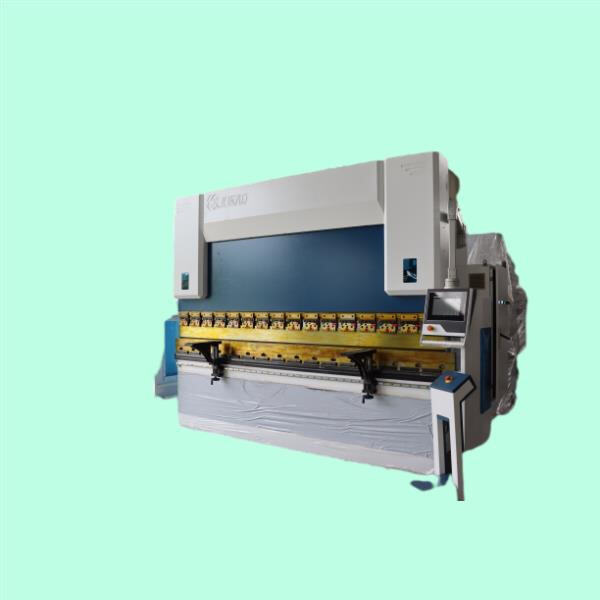

The next generation of electric press brake machines have been designed to open doors in productivity in metalworking, but with them also come the automation and remote capabilities. Therefore they are employed in the purpose of one bend only to it and from a vast variety distance observation.

To sum it up, the electric press brake machine is indeed a metalworking miracle. The modern and extensive features enabled it to have transformed the sheet metal bending process as well by introducing new advantages over traditional technologies. The metalworking industry gets this unrivalled addition to the manufacturing scenario that is bound to make it possible for them revel in higher rates of productivity.

Electric press brake machine aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.

Press Electric press brake machine renowned efficiency accuracy used many metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting fulfill requirements complex patterns; Rolling Machines specialized forming metal sheets ensure top quality production. Pipe Bending Machines offers flexible pipe bend solutions. product line focuses efficiency, precision, stability help customers improve production efficiency product quality.

Press brakes ideal Electric press brake machine tasks require high pressure precision; Laser cutting machines deal range different materials with efficient high-precision cutting capabilities; Rolling machines, outstanding forming capabilities well efficient production, satisfy needs large variety customers. Pipe bending machines used mass production due adaptability stability. machines embody essence latest industrial technology allow manufacturing industry meet challenges today efficiently precision, speed flexibility.

Quality Builds Electric press brake machine: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.