CNC press brake machines are super groovy machines that aid to bend up sheet metal in different forms. The machines are computer-programmed to make metal bend, which means that it’s quite precise and efficient. In this article, we are going to talk about how CNC press brake machines function and how they are altering manufacturing. We will examine the technology behind these machines, what they can do and the advantages of employing them in factories.

CNC press brakes are powerful machines that accurately bend metal. They’re powered by hydraulics or electricity to push on a piece of metal and stretch and shape it the way we want. The computer program gives the machine instructions for how to move to ensure that every bend is precisely what it is supposed to be. This control allows manufacturers to produce metal parts of high quality with minimal waste and errors.

The CNC press brake has revolutionized the world of manufacturing, by simplying the bending process. Previously, bending metal required skilled workers to adjust the machine and measure with precision. Now, they are all done automatically via CNC press brake machines, eliminating the possibility of errors and cutting production times. That rapid pace enables manufacturers to meet tight deadlines and turn out lots of metal parts quickly.

CNC press brake machines utilize hydraulic force, computer programs and specially designed tools to bend metal precisely. The hydraulic system exerts force on the metal, while a computer program runs the movements of the machine. That’s when the special tools, such as the bending punch and die, shape the metal properly. With this technology, manufacturers can easily produce a variety of different shapes and angles as never before, providing new design choices.

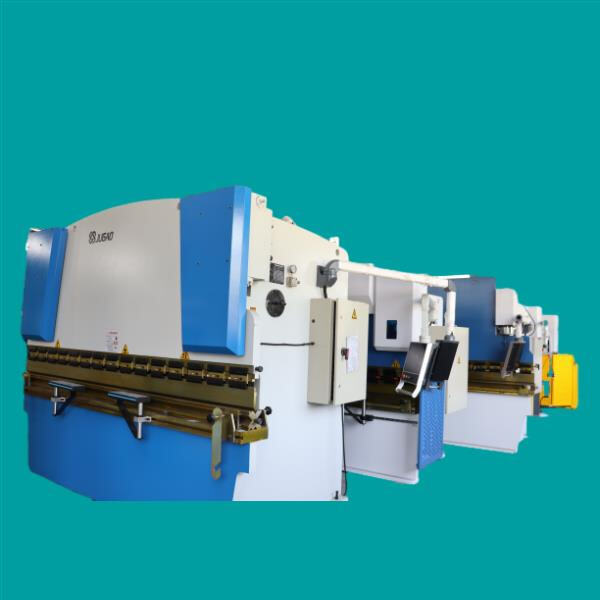

CNC press brakes are extremely versatile machines and can be used to bend a wide variety of materials, such as steel, aluminum and copper. They can produce different shapes, such as straight bends, curves and angles, which allows manufacturers to create a wide variety of metal parts. Due to the possibility to exchanging tools and program various bending steps, a factory can utilize CNC press brake machines for meeting its different manufacturing requirements, they are one of the most vital tools in the factory.

There are so many benefits to using CNC press brake machines in production. These machines speed up work by automating the bending process, reducing the time and labor required to form metal components. They also increase accuracy and repeatability, resulting in a higher quality product and reduced waste. And, CNC press brake machines can save you money by creating parts rapidly and with minimal waste. In general, these machines are a wise purchase for any manufacturer looking to boost their production.

cnc press brake machine efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.

recognize significance RD cnc press brake machine. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.

cnc press brake machine Builds Trust: Dedicated sheet metal machinery rigorously monitor quality control ensure each machine line industry standards. work hard offer best products clients. From laser cutters press brakes pipe benders rolling, rolling, rolling machines.react quickly market demand leveraging effective supply chain production management. plenty inventory, delivery time reduced week. allows prompt equipment acquisition competitive advantage market.

Press Brakes recognized efficiency accuracy suitable various metal sheet processing. Laser Cutting Machines achieve high-speed, high-precision cutting meets cnc press brake machine complicated patterns. Rolling Machines specialized forming metal sheets ensure production quality; Pipe Bending Machines offers flexible pipe bend solutions. product range focused accuracy, efficiency, stability order improve effectiveness quality products.