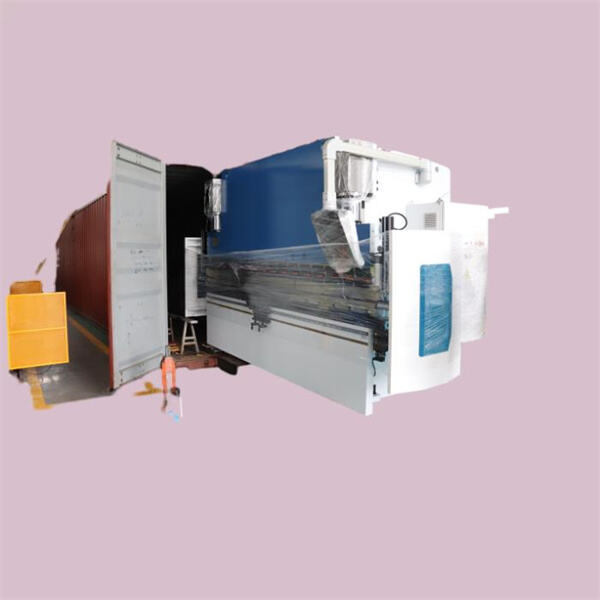

And a tandem press brake is a very important machine tool to accomplish this bending and shaping of metal. It’s a large, powerful tool that can shape metal in a variety of ways.

A brake machine works to bend metal by pressing down on it. It has a large arm that forces the metal against a flat surface. It causes the metal to curve or fold in the direction you intend. Brake machines come in various varieties, but they ultimately function the same.

Some tandem press brake machines are powered by hydraulic force to push the metal downward. THAT STARTS another machine into life, squirting liquid onto a piece of metal. They are also used to swell doughs for breads and pizzas, and as a general work surface. Brakes come in many styles, and some are quite large. Hydraulic press brake machines are often stronger and can bend thicker metal, while mechanical press brake machines are more precise and are easier to maintain.

Maintaining your brake machine is the key to keeping it in good shape. It should be kept clean from dust. If it is a hydraulic brake machine, never fail to see the oil level frequently. If you notice any issues, repair them immediately so that your brake machine stays in good condition.

It’s very important to be conscious in safety when using a brake machine. And be sure to always put on some safety goggles to protect your eyes from any flying metal bits. The hands should be protected with gloves. Do not put your fingers on the operational part of the machine. Never attempt to form material that is too thick for the brake machine.

To optimize your brake machine output, be meticulous in your bend planning. Measure and even mark your metal prior to bending. Take your sweet time about it, and don’t rush. If you bend metal too fast, you can mess up. The more you brake-machine, the better you will be at brake-machining.