- Overview

- Inquiry

- Related Products

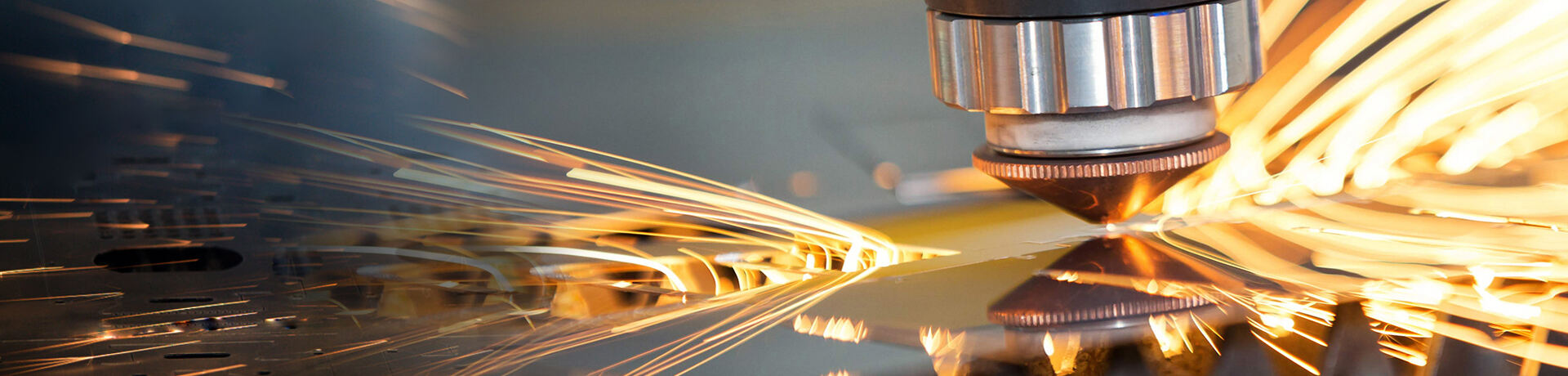

By using program-controlled robot can weld sharp parts with specific routine. It 's applicable to a variety of precision welding processes, including spot welding, seam welding and overlap welding.The laser welding machine adopts high-octane laser pulse to heat one particular area of tiny areas on a work material. The powerful energy of laser radiation diffuses into materials' internal parts through heat conduction, and then the melting material will form a specific molten bath to facilitate the laser welding.

Features and Advantages

1. The machine is easy to handle and don't need the professional welder.

2. High quality and very stable: With a long lifespan to 100000 hours and free of maintain.

3. High efficiency, capable for various welding process: jam welding, seal welding, spot welding, stitch welding and overlap welding .

4. Inappreciable heat-affected zone, little deformation good-looking smoothly welding seam.

5. Little remedial work after welding, high-quality of welding line, precise control of positioning accuracy, small spot focus and automated welding.

6. Use program-controlled robot can weld sharp parts with specific routine.

Application

Robot laser welding machine is standard robot arm cooperate with laser welding machine, which is suitable for precision welding, complicated welding and mass production. It is widely applied to many fields, such as 3C,medical devices, automobiles, railways, ships, aviation, air conditioning condensers, home decoration, elevators, power batteries,etc.

Technical Parameters

| Laser power | 1000w | 1500w | 2000w |

| Conduction Type | Fiber laser | Fiber laser | Fiber laser |

| Laser wavelength | 1064nm | 1064nm | 1064nm |

| Cooling Method | Water cooling | Water cooling | Water cooling |

| Total Power | 11.1kw | 13.3kw | 15.1kw |

| Repositioning Accuracy | 0.04mm | 0.04mm | 0.04mm |

| Machine Weight | 650kg | 650kg | 700kg |

| Welding Mode | Dot/Cricle/Line/8 mode | Dot/Cricle/Line/8 mode | Dot/Cricle/Line/8 mode |

| Spot Diameyer | 0.1-6mm | 0.1-6mm | 0.1-6mm |

| Welding penetration | 4mm | 5mm | 6mm |

| Machine Dimension | 1187*600*1200mm | 1187*600*1200mm | 1187*600*1200mm |