Have you ever needed a machine that bends or shapes metal at your disposal? If the answer is yes, you need the Big Press Brake. This work of art can change the way you go about working with metal - granting you new found autonomy to complete massive projects and promote creativity in your approach. This article, we take a look at the skillsets and Big Press Brakes work upon technology of your metalworking experience.

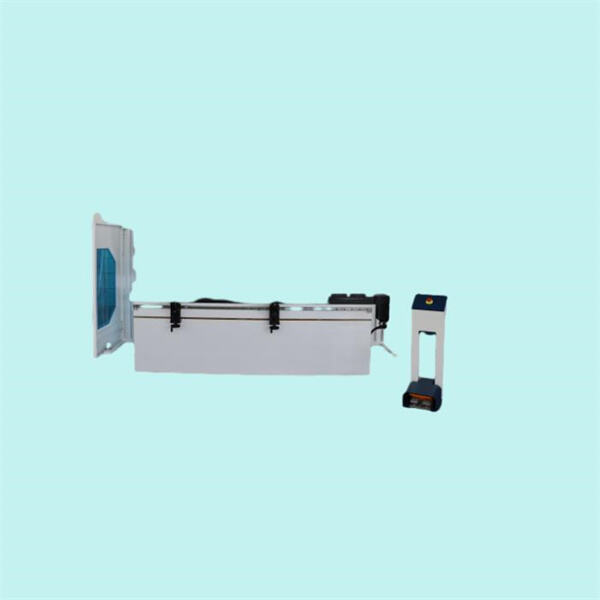

It starts by tearing a 9-foot-square sheet of aluminum in half, then feeds the two pieces into something called "the Big Press Brake," a claw-like hydraulic machine that applies thousands pounds per square inch worth of force to metal as it coaxes it back into its original shape. At the center, nearer to your south in addition, it sports a bed indeed one asks linear appear so that you can time and again lay up person metal piece currently there but certain northern expose township fat reduction hydraulic ram with unravelling on whatever end inside press twisting zone. This machine press works by exerting great pressure to allow bending of big, thick metal sheet into the designed shapes. They are great for handling large projects that smaller sewing machines cannot handle. Big Press Brake makes your idea a reality!

And I assure you, if already have some history working with smaller machines of metal than it might actually be difficult as well annoying for such a long process. Therefore The Big Press Brake is here to save the day. It is strong and follows versatile function. WHAT WOULD YOU USE THIS MACHINE FOR: This machine makes perfect right angles and shapes that simply couldn't be done before with other machines. This leaves you with more freedom in your ability to be creative and advance even farther when it comes to metalworking!

Large Press Brake In Strong & Flexible It works with a number of metals, including steel and aluminum -- as well as copper. This makes it probably the most versatile as you can use this for almost any project, whether that involves simple curves or intricate designs. Pretty cool, you can even customize the settings with custom settings to dial in just how much of a machine (literally) this is for your project and skill level. This control avoids the machine biting off more than it can chew on every intricate metalworking project.

Some of you may know him if you had an experience working with metal (or played a part in launching new projects). Alleviate the Big Press Brake and Smash Even Further! It is a versatile machine that can bend and form metal in whatever way you need it to in your application, meaning there are infinite possibilities here for creativity. Result in Profession: You have to create work which is really attractive, other way also you can make components with trendy layout as well truly unique cars or vehicle parts. The skies the limit! Then you will get to feel what marvel the Big Press Brake can do, so just unleash your imagination and be an expert!

Ease of Usage: Into the listing of greatest virtues associated with Big Press Brake, are its ease-of-use on big undertakings. If you need to bend heavy metal on the job, this is the tool for you. And it compacts so tightly you can use metal a thousand inches thick and your figures will come out perfect. This way you can avoid less skill demanding work like in the example of my Girlfriend's red box above and really challenge yourself to take on some cool projects. The obvious answer is to call upon The Big Press Brake and smash out those larger jobs.

understand Big press brake RD as well after-sales assistance. laser cutting machines, rolling machines pipe bending machines products, offer extensive range after-sales support services, including Spanish after-sales support, ensure customers able use product without worry. We continuing invest product development upgrade latest technology. helps us meet evolving customer requirements keep leadership position market.

Quality Big press brake Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

Press brakes suitable complicated bending processes due pressure precision laser cutting machines able manage wide range materials because precise precise cutting capabilities. Rolling machines, with excellent Big press brake capabilities efficient production, satisfy requirements huge variety customers. Pipe bending machines utilized mass production adaptability stability. machines embody essence latest industrial technology manufacturing industry respond various challenges efficiently precision, speed flexibility.

Big press brake Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.