Are you looking to take the hassle and frustration out of your sheet metal projects? Using a 12 ft sheet metal brake can make all the difference! Use this sturdy and stable tool that also helps in the filing of metals sheets as you mould them. Which will produce great looking products easily with least effort.

Using a 12ft sheet metal brake allows for accurate bends every time This large size of this tool as well the robust hydraulic system it uses provides you with great control over how to bend the metal. That is how you achieve professional looking clean and nice finishes. Siding Metal Roofing Big Precise Jobs It's so simple how to do bends.

Another great advantage of a 12 ft sheet metal brake is that it allows you to work faster as well. As opposed to bending small slugs of metal one at a time, and you can bend enormous areas of sheet metallic all in parallel. Its interpretation is, all your projects done as soon as quicker than before. It is a very handy feature for high-traffic stores but also DIYers at home. This will enable you to take on larger, more ambitious projects that may have previously been daunting.

12 ft sheet metal brake accuracy - hard to believe. There is a unique digital readout built into this machine to display the position of every bending angle. You will no longer need to guess or wonder if you are doing anything wrong. The result you get are far superior than if the metal were bent by hand. This extra precision will make sure that all looks well and is glued properly. You could get a decent boost in the quality of your work from using this.

There are several different things that a 12 ft brake can be used to make for custom sheet metal projects. From awesome metal art to unique roof designs. This tool lets you unleash your creativity to create anything that comes into sight. Experiment with different materials (or further work on the ones you know) and WOW yourself all over again. With a 12 ft brake you can make something useful or just play - the sky's the limit.

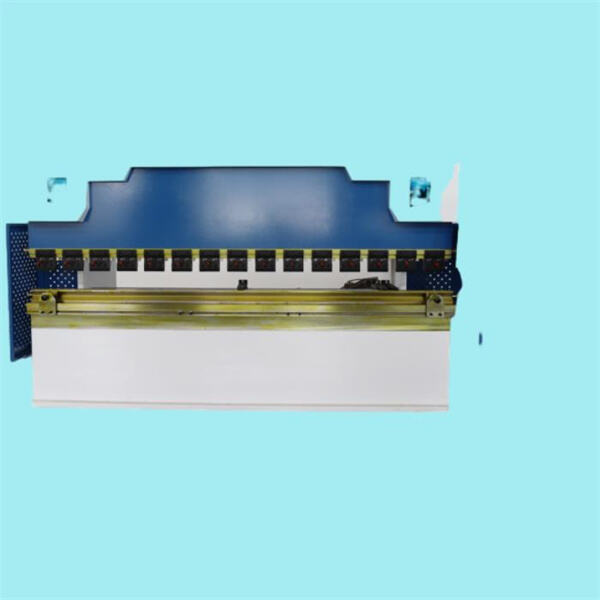

Press Brakes recognized efficiency accuracy suitable various metal sheet processing. Laser Cutting Machines achieve high-speed, high-precision cutting meets 12 ft sheet metal brake complicated patterns. Rolling Machines specialized forming metal sheets ensure production quality; Pipe Bending Machines offers flexible pipe bend solutions. product range focused accuracy, efficiency, stability order improve effectiveness quality products.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective 12 ft sheet metal brake production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle 12 ft sheet metal brake materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.

know importance service sales RD 12 ft sheet metal brake. laser cutting machines, rolling machines pipe bending machinery many products, offer entire range after-sales assistance services, Spanish after-sales service make sure customers enjoy hassle-free experience. continue invest product development upgrade technology innovation. helps adapt changing needs customers keep leadership position marketplace.