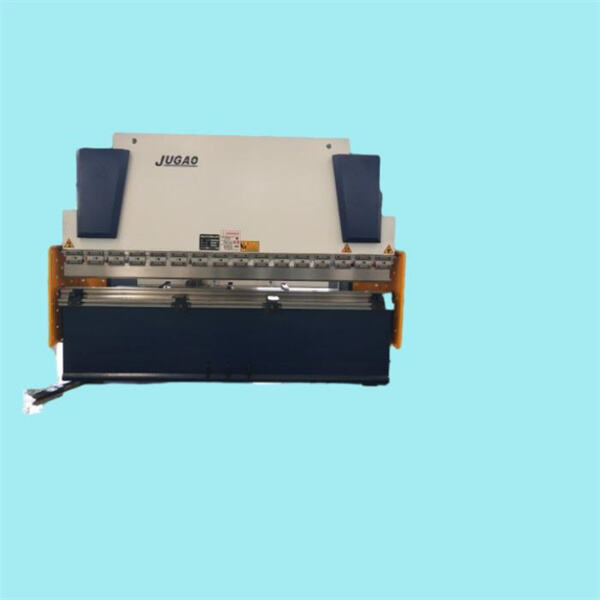

Ever see a small press brake? One thing that makes a sheet metal bender an essential is because it can shape not only bend metals but also a variety of other materials in your workshop. It is very small, but still does its work great and can support you to create numerous kinds of items. In this blog post we will see more about those nifty tool and how you can make it work for your workshop.

The small press brake is actually quite compact.... one of its greatest benefits. This is great if your workshop is already overflowing with tools and materials, or you just have very little space to work in. When it comes to the small press brake, you are going with an option that is not very big and bulky. Despite its small size, it also has a great capacity for bending material which is really helpful if space around you is limited and still allows you to do plenty of work.

A second key advantage of the small press brake is its precision. You can develop great bends in your materials with ease. Perfect bends can make all the difference in how your final product looks, whether you are building something that requires a lot of detail or just doing some light project metal bending. The small press brake assures you that the work will always be at its best no matter how many times you are using it.

Do you now that the small press brake is able to bend different materials? It's true! You can use it with aluminum, steel, copper and even they are compatible in the production of other materials. It is well organized and perfect for a wide range of materials you may be working with in your workshop. You do not have to keep worrying about swapping equipment or using another one with regard to different sorts of products; your small press brake will be able to assist them all. This flexibility makes for a great addition to any workspace.

Now for the small press brake: Fast as Hell For example you will follow it in less time to finish a lot of work. This is particularly useful when working on a large interface with many steps, allowing you to focus and avoid feeling overwhelmed. This will allow you to pump out a lot in very little time, saving countless hours getting the job done on your terms rather than embarking upon deadlines or having any reasons for turning away work altogether.

Small press brake Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.

Quality Builds Trust. believe sheet metal equipment make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines strive provide top-quality products ease anxiety customers.We respond rapidly market Small press brake using effective supply chain production management. ample inventory, delivery time shortened one week, allows rapid acquisition equipment gaining advantage market.

Small press brake aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.

Small press brake efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.