Cutting is one of the most widely used job process in metalworking. The most important process used to manufacture metals based on shapes or thicknesses. In addition to its limited construction use, these materials are used for the manufacture of virtually all types of items including tools and countless machine components. Pre-Trained Humans Are Required To Cut Metal This requires lots of practice and skill is absolutely nothing but a cut. Metal Shear Press For a metal worker, the shear press have made their task of cutting metals through and through.

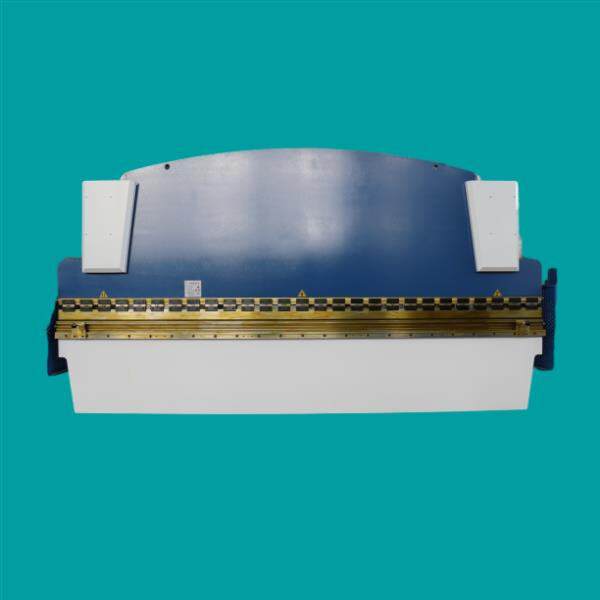

The metal shear press as mentioned here is a unique machine and it can be used for the direct embossing of all types of metals. It is all here; you just have to push down a little piece of metal, snap it in two easy parts along the line. The mechanism is powerful enough to take on the most challenging job of slicing thick metal sheets effortlessly. For many projects, this is important because the metal has very nice clean edges after being cut.

This metal shear press is mainly characterized by the high degree of accuracy in cutting and at considerable speed. But in an era of 3D printing that is literally out-of-this-world (did I mention on the printer they use IN SPACE), every piece can be tailored to expert standards and hey presto, no long headache for workers trying to cut metal nice n careful while making odd-shaped-fine-work-y-things from scratch. Needless to say, it also allows for metal cutting immediately and has them producing their work earlier. That works well if you have a lot of pieces to cut.

Any metalworking shop will need a decent quality metal shear press to create an even product from their starting stock. Thus, it saves time as well as the effort of cutting metal by hand. The shear press employees work on allows them to cut dozens of pieces metal in minutes. This has made them able to organize the projects, and deliver their project on time much effectively. This can save high volume shops several minutes a day and allow shop owners to squeeze more work into their days.

The Sheet Metal Shear Press: This is a very powerful machine which powerfully cuts all types of sheet metals easily, without any extra effort. Businesses that deal heavily in hard alloys, like construction and manufacturing operations may definitely be able to see the value of having this machine as part of their mix. It removes much material and does so very accurately. It is very critical to use in metalworking jobs like welding for ensuring the pieces will are contract with each other and everything works as it should.

Essentially, every metalworking shop should have a shear press that can process various material types. It is configured to shear almost any metal, including aluminum, copper and brass. It is easy for workers to work with as it can be used on many materials which makes for a quick turn over between tasks and jobs. This is a bit more necessary in metalworking, as seen from the wide variety of projects that call for different base metals.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective Metal shear press production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.

Press brakes suitable bending complex operations due high pressure precision; Laser cutting machines manage wide range materials thanks powerful high-precision cutting capabilities; Metal shear press, thanks their exceptional forming capabilities efficient production, satisfy needs large variety clients. Pipe bending machines utilized mass production due flexibility stability. machines core latest industrial technology assist manufacturing industry meet challenges today efficiently quickly, precisely high degree flexibility.

aware importance after-sales service RD innovation. provide array after-sales solutions such Metal shear pressg after-sales press brakes, various products. same time, continue invest research development, support improvements products using latest technologies meet evolving needs customers help customers maintain leading position marketplace.

Press Brakes known reliability precision Metal shear press various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.